Powered rat-hole offline stand column connecting and unloading system and stand column connecting and unloading method

A rathole and column technology, which is applied in earthwork drilling, drilling equipment, drill pipes, etc., can solve the problems that are not conducive to the weight loss of the rig floor, the rathole occupies a large space on the rig floor, and the rathole interferes with the riser. Achieve the effect of realizing fully automatic control, improving operation efficiency and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

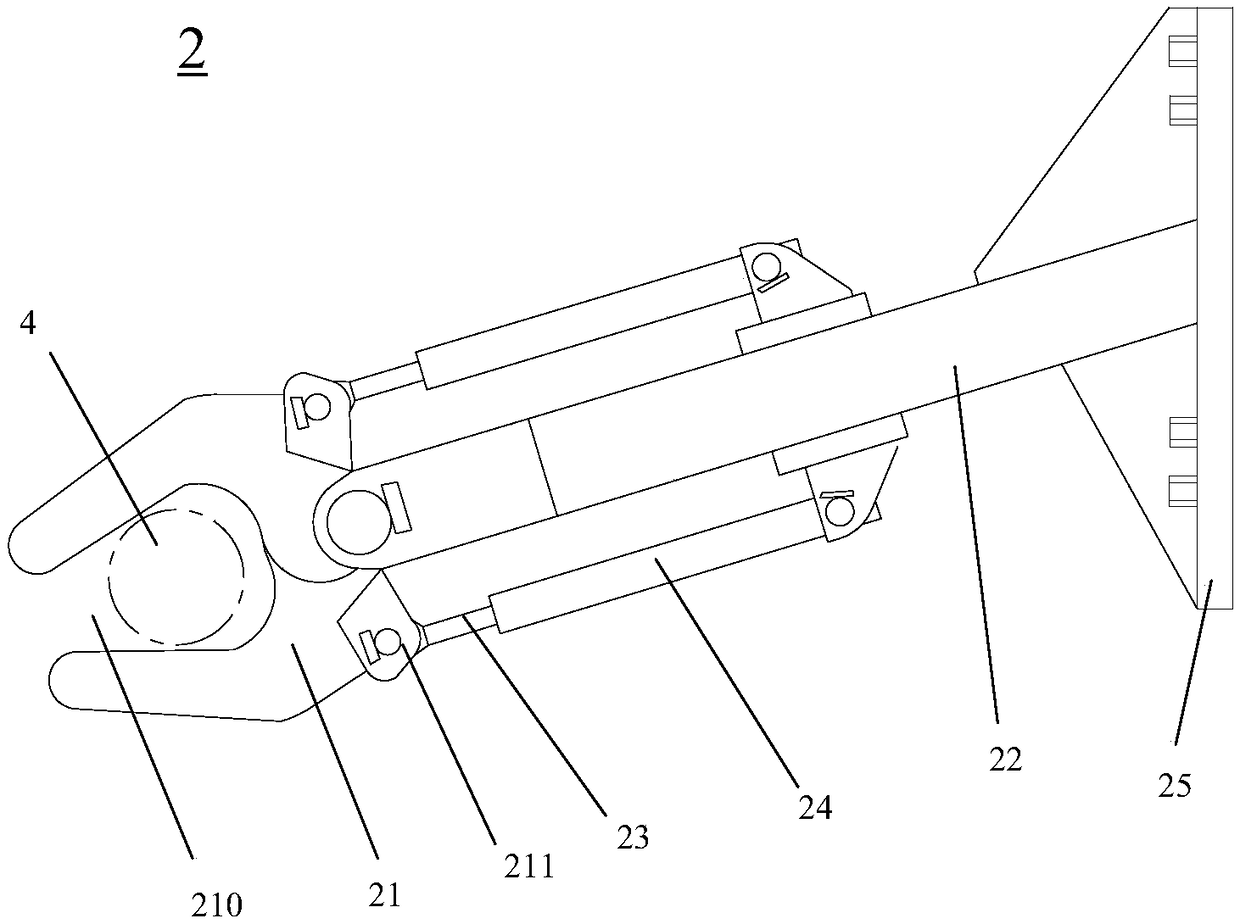

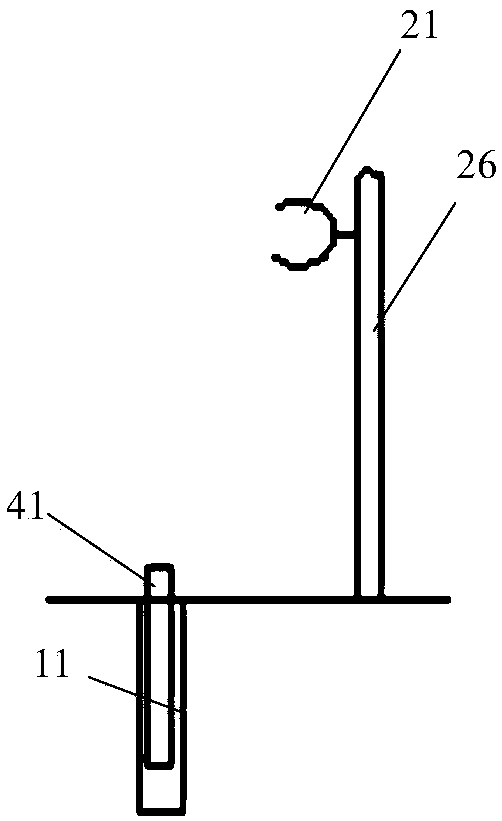

[0058] In order to make the purpose, technical solution and advantages of the present invention more clear, the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined arbitrarily with each other. The stand box, clamping arm, clamping hydraulic device, and piston rod structure in the accompanying drawings only illustrate one group, and the rest of the unillustrated parts are the same in structure and principle as the schematic ones.

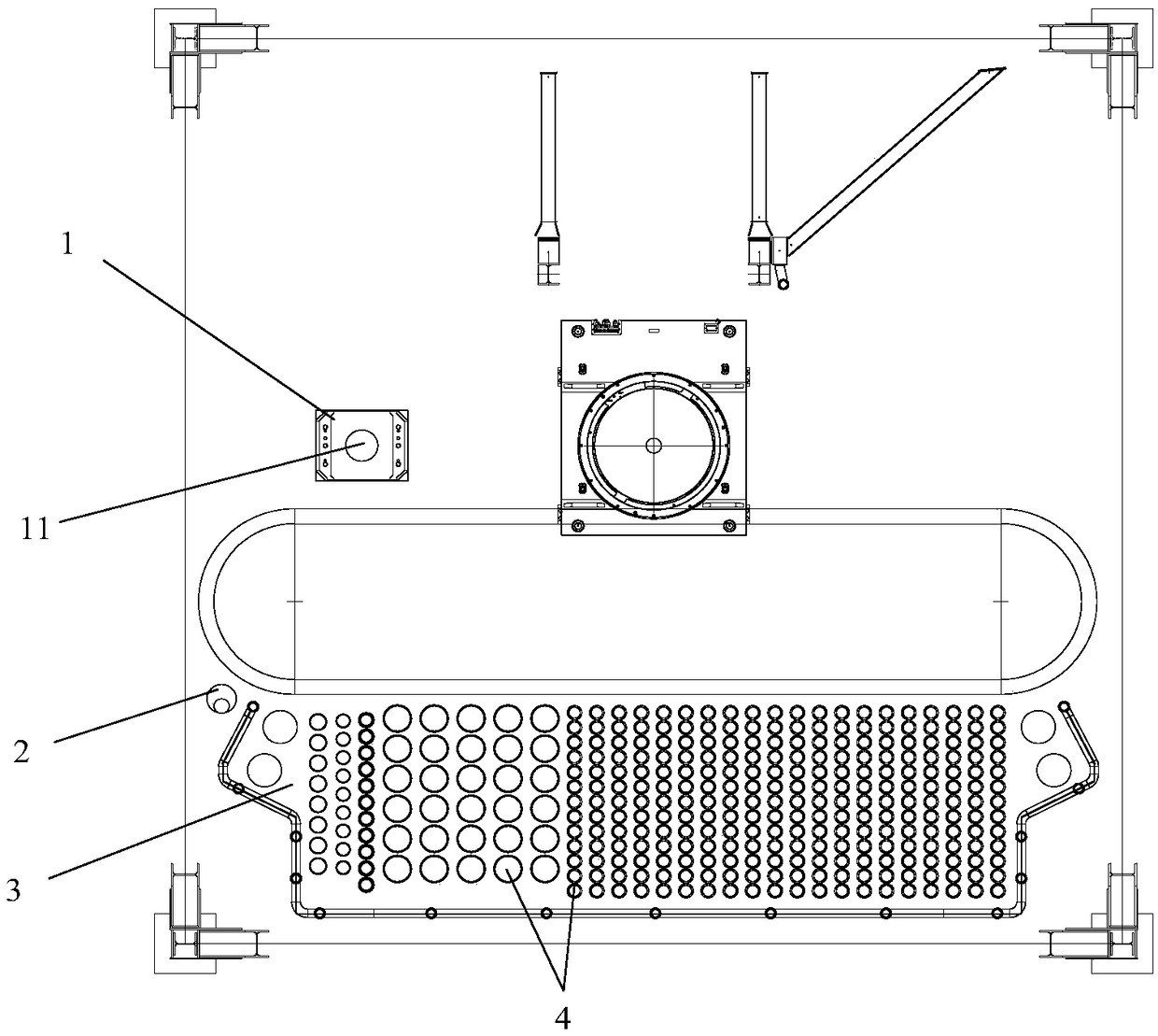

[0059] In order to solve the above-mentioned technical problems, the embodiment of the present invention provides a power rathole off-line connection and removal column system with simple structure, small weight, low power consumption and low cost. in, figure 1 It is a top view schematic diagram of the overall structure of the power rathol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com