A method and device for multi-point recovery and efficient utilization of waste heat at the tail of a sintering machine

A sintering machine, multi-point technology, applied in the field of sinter production in the iron and steel industry, can solve the problems of unstable steam quality, harsh operating environment, incomplete waste heat recovery, etc.

Active Publication Date: 2019-10-01

ZHONGYE-CHANGTIAN INT ENG CO LTD

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

(1) Waste heat recovery is not complete;

(2) The operating environment near the return lane is harsh;

(3) The adjustment method is not flexible, the quality of steam production is unstable, and it cannot meet the various heat needs of users

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

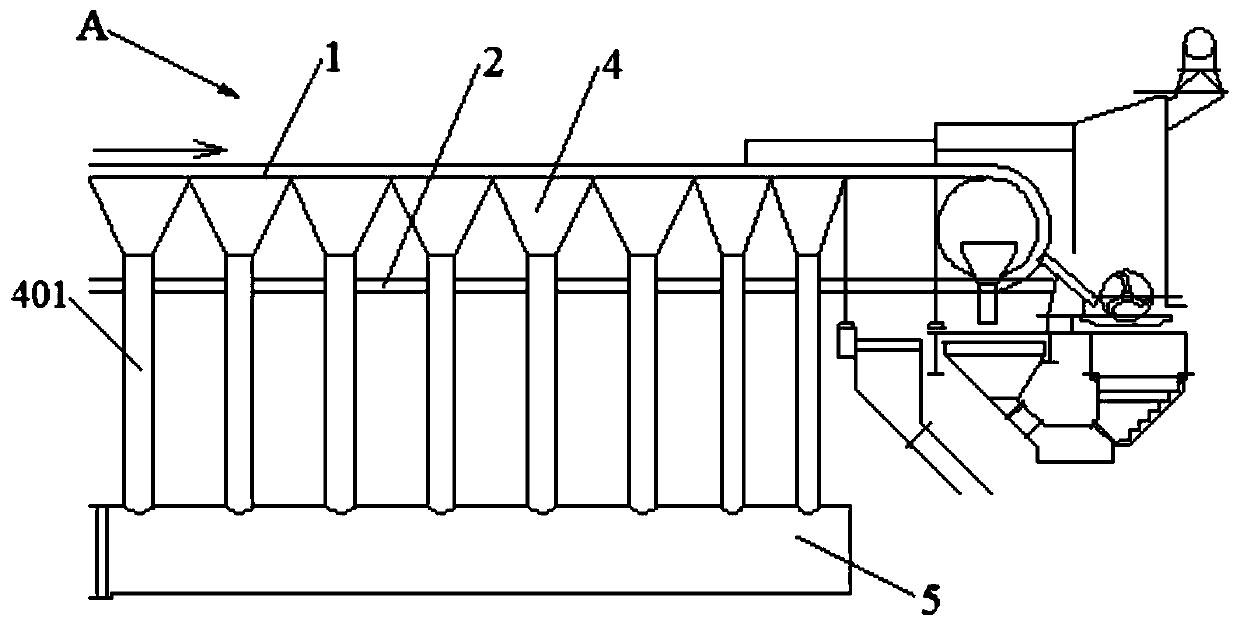

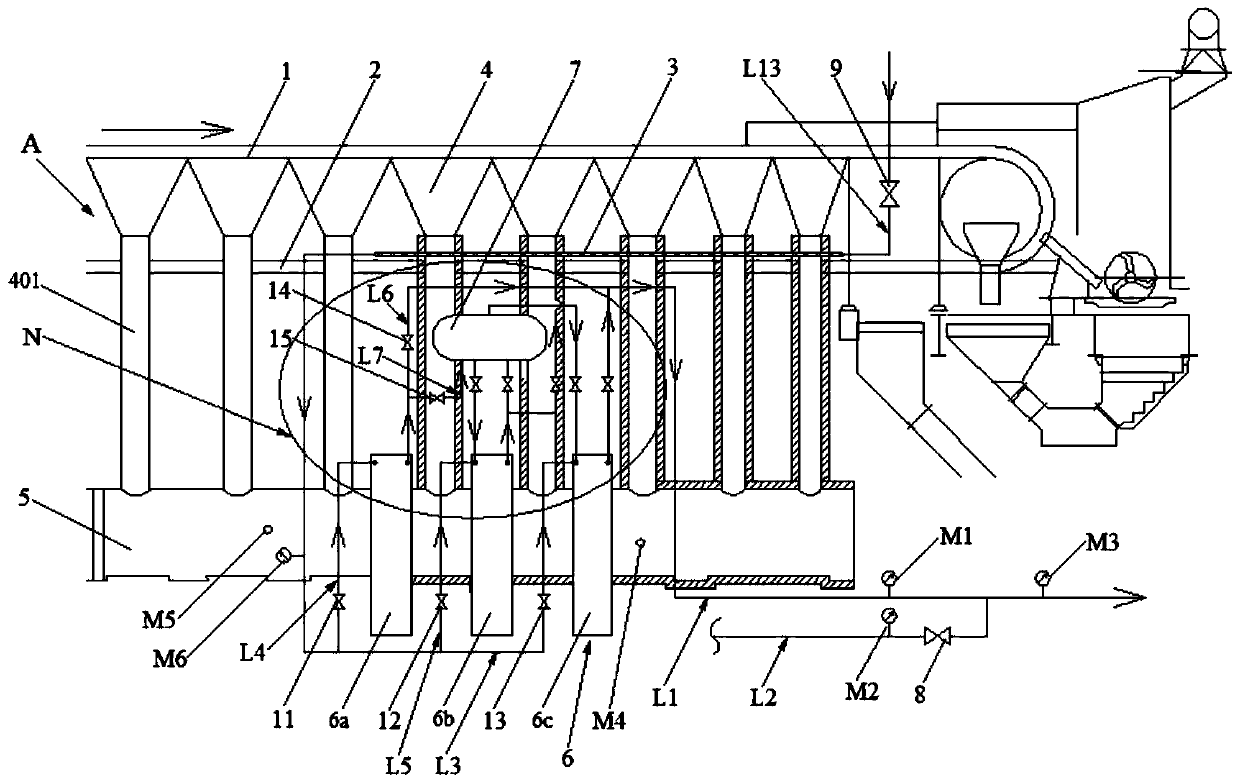

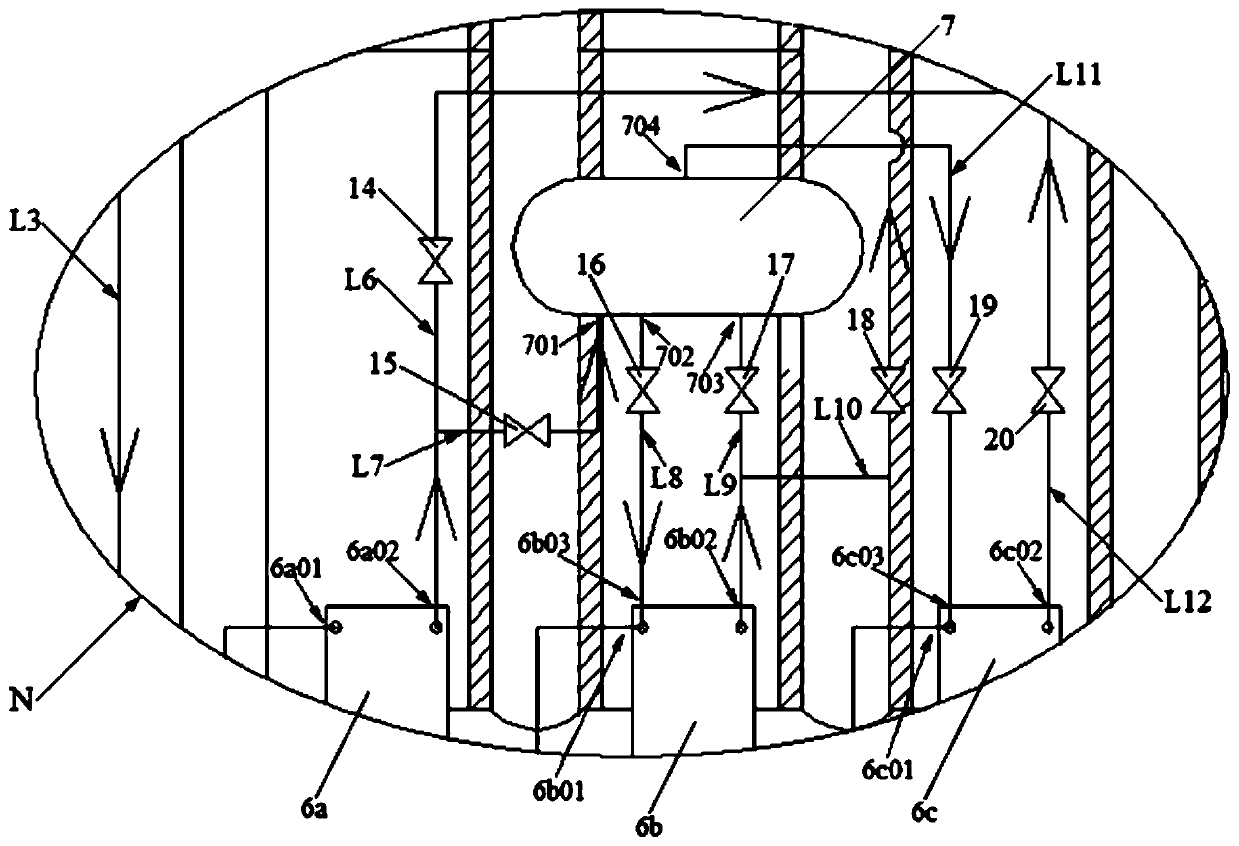

Disclosed is a method for multi-point recovery and efficient utilization of waste heat at the tail of a sintering machine. The method includes the following steps that (1) a sintering mixture is put on a sintering machine trolley 1 for ignition, and sintering is started; (2) a radiation heat exchanger 3 is arranged above a turning lane 2 at the tail of the sintering machine, fed water enters the radiation heat exchanger 3 and carries out heat exchange with the empty trolley 1 above the turning lane 2, and the fed water is heated into low-temperature water; (3) convection heat exchangers 6 arearranged in the positions, corresponding to a plurality of air boxes 4 at the tail of the sintering machine, of a flue 5, the low-temperature water enters the convection heat exchangers 6 and carriesout heat exchange with high-temperature flue gas in the flue 5, and steam is generated after the low-temperature water is heated through the high-temperature flue gas; and (4) the steam is used by users. Through comprehensive multi-point recovery of the waste heat of the high-temperature flue gas and sensible heat of the turning lane at the tail of the sintering machine, the waste heat recovery and utilization rate is increased, and the operating environment nearby the turning lane is improved.

Description

technical field The invention relates to a sinter tail waste heat utilization device, in particular to a method and device for multi-point recovery and efficient utilization of sinter tail waste heat, belonging to the field of sinter production in the iron and steel industry. Background technique The waste heat resources carried by 1 ton of sinter ore in large and medium-sized iron and steel enterprises in my country are about 0.94-1.02GJ, accounting for about 65%-71% and 11%-12% of the total waste heat resources in the sintering process and iron and steel enterprises, respectively. Compared with large and medium-sized iron and steel enterprises in developed countries, the recovery rate of sinter waste heat resources in my country's iron and steel enterprises is lower than the average level of 30% to 45% of major foreign large and medium-sized iron and steel enterprises, only 28% to 30%. Therefore, the efficient recovery and utilization of sinter waste heat resources has bec...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): F27D17/00F22B1/18

CPCF22B1/1892F27D17/004F27D2017/006Y02P10/25

Inventor 周浩宇刘前

Owner ZHONGYE-CHANGTIAN INT ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com