Non-contact type optical measurement method for thickness of thick photoresist film

A non-contact, thick photoresist technology, applied in measurement devices, optical devices, instruments, etc., can solve the problem of insufficiency of measurement methods, and achieve the effect of improving production accuracy and success rate and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

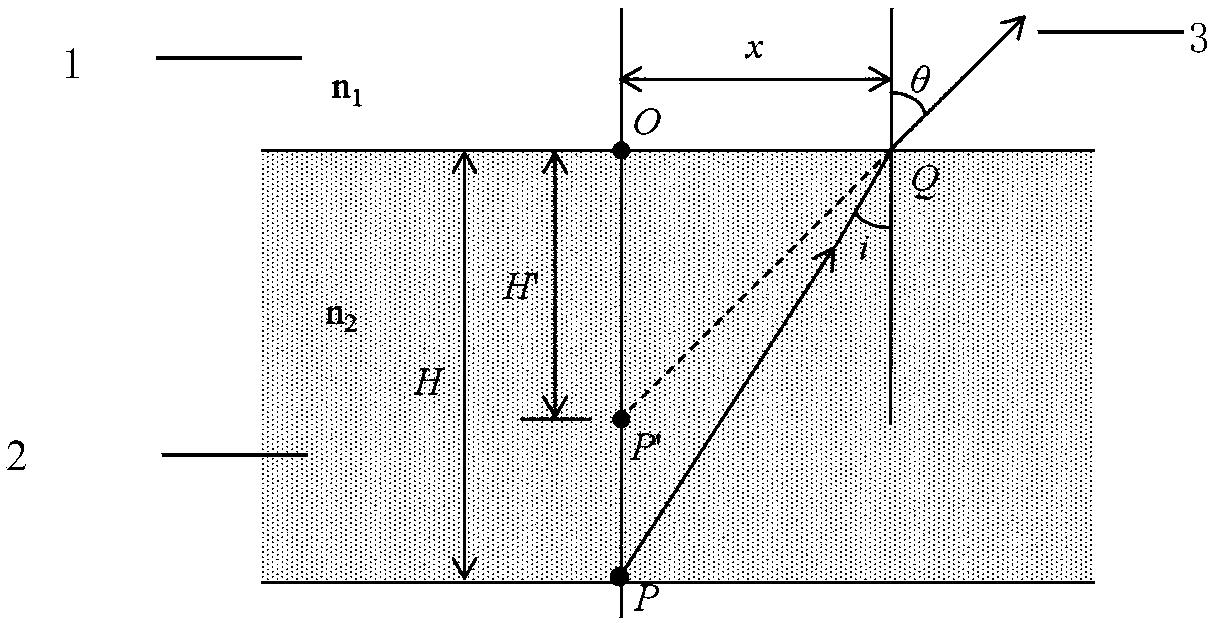

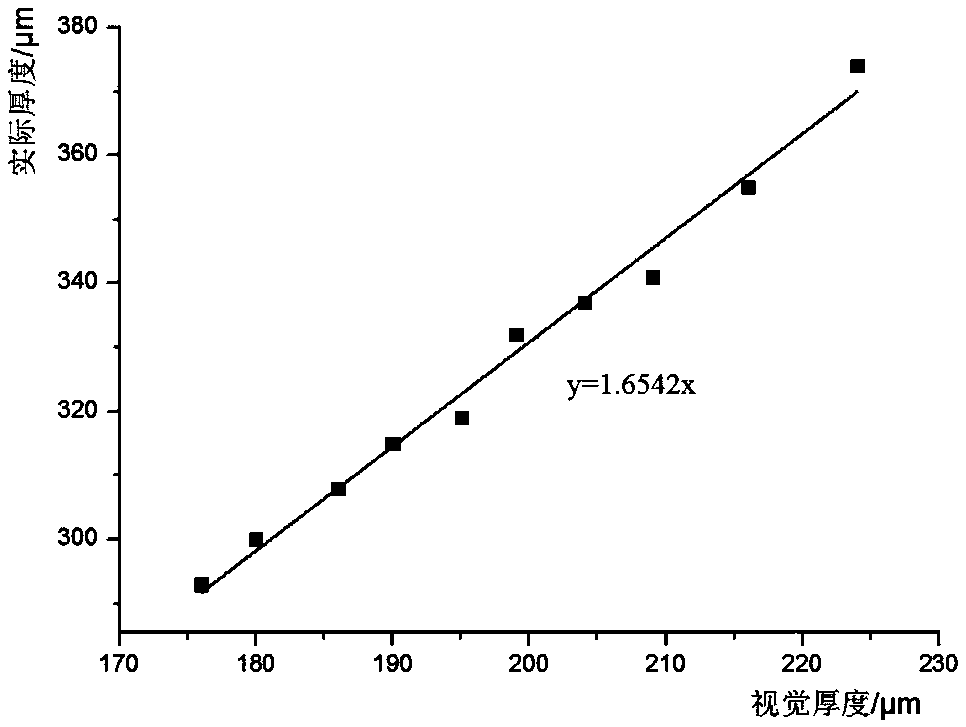

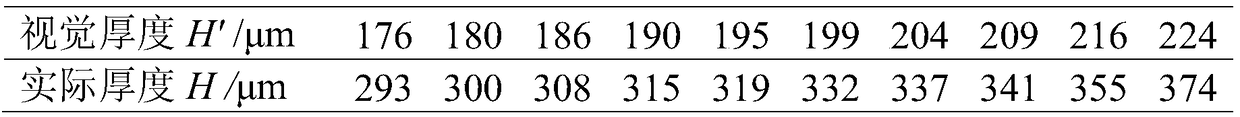

[0023] attached figure 1 It is a schematic diagram of the measurement principle of thick film thickness based on the refractive index. Combining the law of refraction of light and the relationship of trigonometric functions, it can be known that the actual thickness of SU-8 glue is the product of the visual thickness and its refractive index, that is, formula (1). based on figure 1 The measurement principle, using figure 2 The refractive index of SU-8 2075 photoresist was calculated. An experimental method for measuring the thickness of a thick photoresist, which comprises the following steps:

[0024] (1) Substrate pretreatment

[0025] Use different types of sandpaper to rough, finely grind, and polish the metal copper substrate to make the surface roughness Ra less than 0.04 μm; use acetone cotton ball to s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com