Electromagnetic shielding polaroid and preparation method thereof

An electromagnetic shielding and polarizer technology, applied in the field of polarizers, can solve the problems of lack of shielding electromagnetic waves, high antenna reflection power, radio frequency interference circuits, etc., to improve performance and experience, shield signal interference, and improve call quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

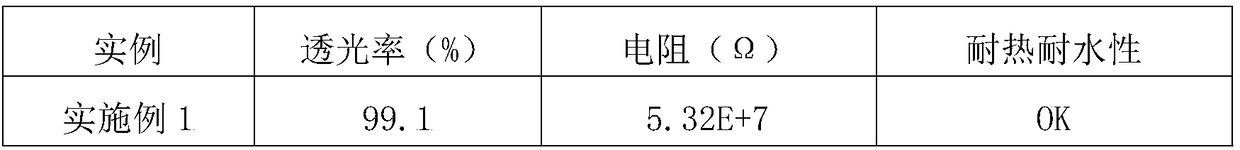

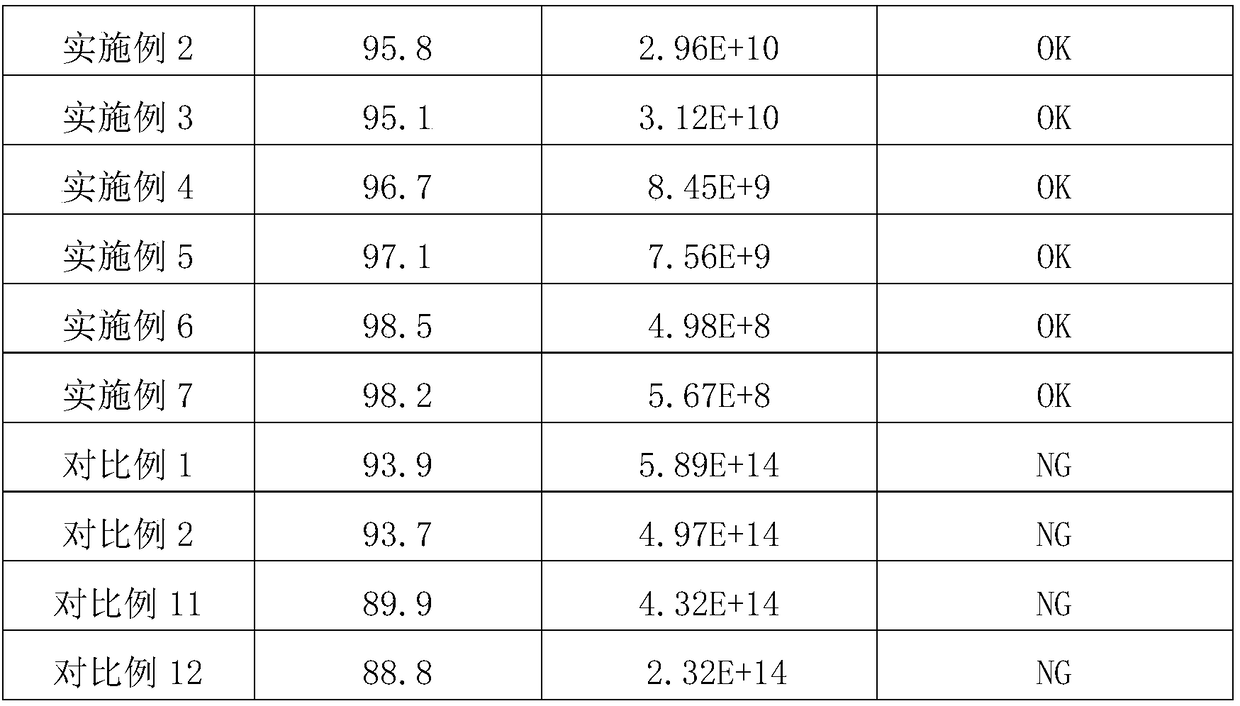

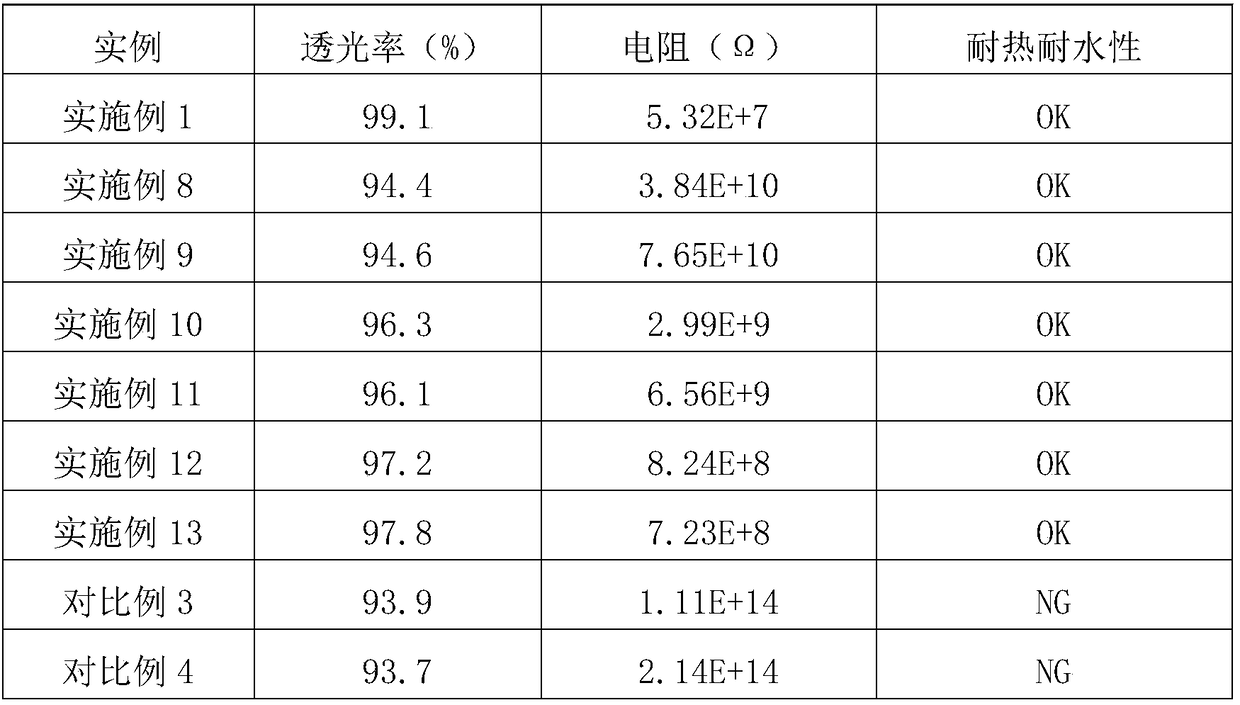

Examples

Embodiment 1

[0024] Example 1 An electromagnetic shielding polarizer, the surface of the outer TAC film is coated with nano-silver wire hardened layer and consists of the following components by weight: 20% by weight of polyurethane acrylic acid monomer, 6% by weight of aliphatic polyurethane Diacrylate, 4% by weight of pentaerythritol triacrylate, 1.5% by weight of photoinitiator 184, 6% by weight of nano silver wire emulsion, 30% by weight of MIBK and 32.5% by weight of PMG.

[0025] The preparation method of the above-mentioned electromagnetic shielding polarizer is carried out as follows:

[0026] (1) the photoinitiator 184, the photoinitiator 184 of the urethane acrylic acid monomer of 20% weight content, the aliphatic polyurethane diacrylate of 6% weight content, the pentaerythritol triacrylate of 4% weight content, 1.5% weight content The nano silver thread emulsion, the MIBK of 30% by weight and the PMG of 32.5% by weight are mixed uniformly to obtain the mixture;

[0027] (2) App...

Embodiment 2

[0030] Embodiment 2 An electromagnetic shielding polarizer, the surface coating nano-silver wire hardening layer of its outer layer TAC film is made up of the following composition of weight content: the polyurethane acrylic acid monomer of 10% weight content, the aliphatic polyurethane of 2% weight content Diacrylate, 1% by weight of pentaerythritol triacrylate, 0.5% by weight of photoinitiator 184, 2% by weight of nano silver wire emulsion, 40% by weight of MIBK and 44.5% by weight of PMG.

[0031] The preparation method of the above-mentioned electromagnetic shielding polarizer is carried out as follows:

[0032] (1) the photoinitiator 184, the photoinitiator 184 of the urethane acrylic acid monomer of 10% weight content, the aliphatic polyurethane diacrylate of 2% weight content, the pentaerythritol triacrylate of 1% weight content, 0.5% weight content The nano silver thread emulsion, the MIBK of 40% by weight and the PMG of 44.5% by weight are mixed uniformly to obtain th...

Embodiment 3

[0036] Embodiment 3 An electromagnetic shielding polarizer, the surface coating nano-silver wire hardening layer of its outer layer TAC film is made up of the following composition of weight content: the polyurethane acrylic acid monomer of 30% weight content, the aliphatic polyurethane of 10% weight content Diacrylate, 10% by weight of pentaerythritol triacrylate, 5% by weight of photoinitiator 184, 10% by weight of nano silver wire emulsion, 15% by weight of MIBK and 20% by weight of PMG.

[0037] The preparation method of the above-mentioned electromagnetic shielding polarizer is carried out as follows:

[0038] (1) the photoinitiator 184, the photoinitiator 184 of the urethane acrylic acid monomer of 30% weight content, the aliphatic polyurethane diacrylate of 10% weight content, the pentaerythritol triacrylate of 10% weight content, 5% weight content The nano-silver wire emulsion, the MIBK of 15% by weight and the PMG of 20% by weight are mixed uniformly to obtain a mixtu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com