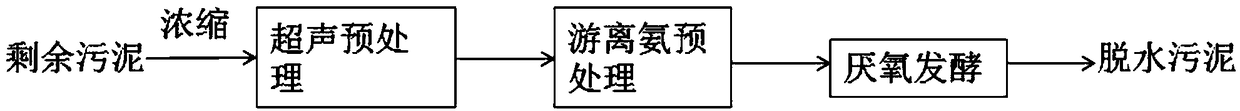

Method for improving dissolving out of organic matter in excess sludge through combined pretreatment

A technology of excess sludge and pretreatment, which is applied in the fields of sludge treatment, biological sludge treatment, chemical instruments and methods, etc., can solve the problems of unsatisfactory sludge dissolution effect, increase the dissolution of organic matter in excess sludge, and achieve decomposition. Fast, energy-dense effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

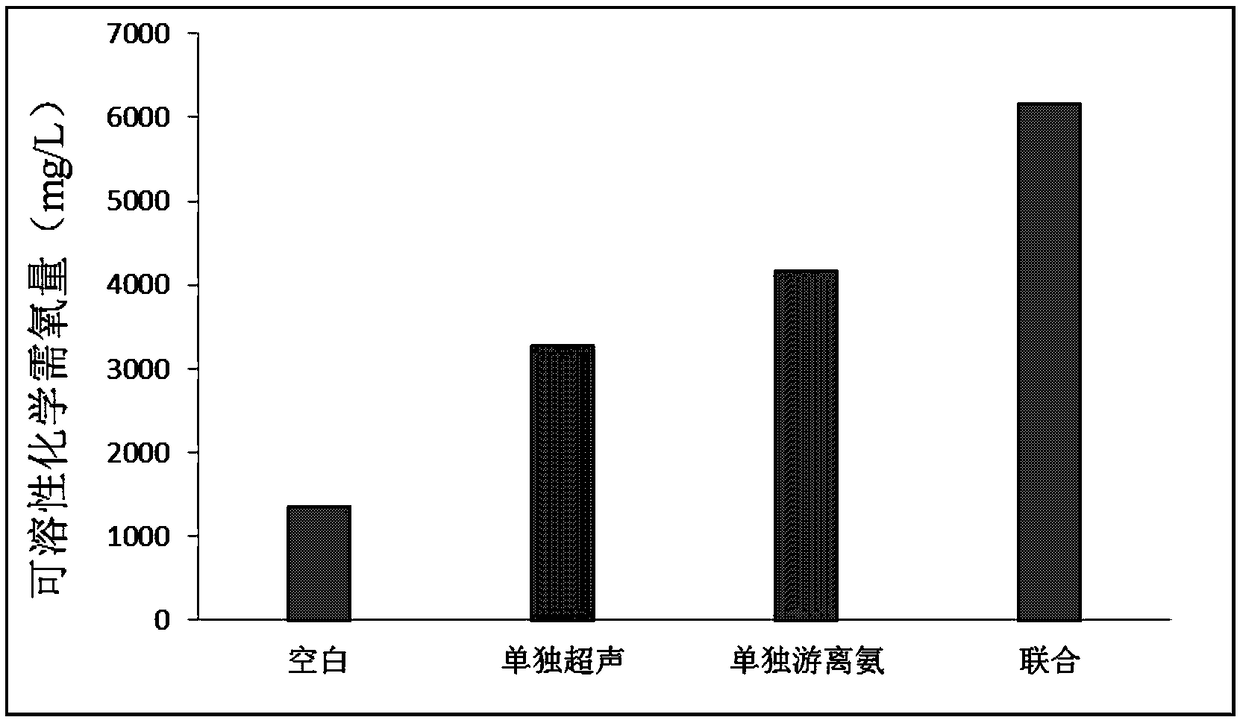

[0019] Firstly, the remaining sludge in the secondary sedimentation tank of the sewage treatment plant is concentrated. After concentration, the TSS of the sludge is 22820mg / l, the VSS is 13920mg / L, the SCOD is 180mg / L, and the pH is 6.82. The processing steps are as follows:

[0020] Step 1: Ultrasonic pretreatment, the ultrasonic sound energy density is 2w / ml, and the ultrasonic time is 15min;

[0021] Step 2: Free ammonia pretreatment, add a certain amount of 4mol / L ammonium chloride solution to the sludge, so that the initial ammonia nitrogen concentration in the remaining sludge is 341mg / L, use 4mol / L NaOH solution and 4mol / L The HCl solution adjusted the pH of the remaining sludge to 9 and maintained it for 48 hours, during which the temperature was controlled at 25±0.1°C (under this condition, the initial free ammonia concentration was 150mg / L), and the sludge mechanical stirring speed was 120rpm / min.

[0022] After the above-mentioned treatment, the dissolved chemical...

Embodiment 2

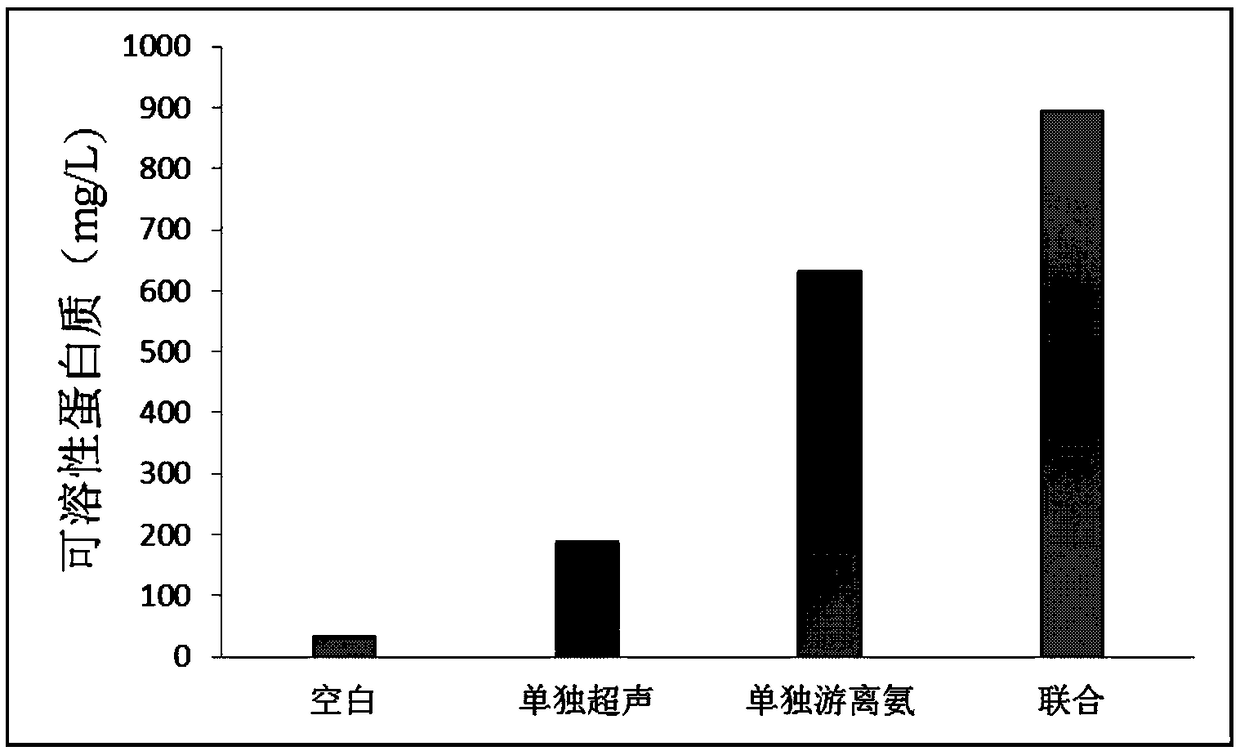

[0024] Firstly, the residual sludge in the secondary sedimentation tank of the sewage treatment plant is concentrated. After concentration, the VSS of the sludge is 13783mg / L, and the sludge is used as the pretreatment substrate. The processing steps are as follows:

[0025] Step 1: Ultrasonic pretreatment, the ultrasonic sound energy density is 1w / ml, and the ultrasonic time is 10min;

[0026] Step 2: Free ammonia pretreatment, add a certain amount of 4mol / L ammonium chloride solution to the sludge, so that the initial ammonia nitrogen concentration in the remaining sludge is 341mg / L, use 4mol / L NaOH solution and 4mol / L The HCl solution adjusted the pH of the remaining sludge to 9 and maintained it for 48 hours, during which the temperature was controlled at 25±0.1°C (under this condition, the initial free ammonia concentration was 150mg / L), and the sludge mechanical stirring speed was 120rpm / min.

[0027] Soluble protein reaches 892mg / L at 48h after above-mentioned treatmen...

Embodiment 3

[0029] Firstly, the residual sludge in the secondary sedimentation tank of the sewage treatment plant is concentrated. After concentration, the VSS of the sludge is 13916mg / L, and the sludge is used as the pretreatment substrate. The processing steps are as follows:

[0030] Step 1: Ultrasonic pretreatment, the ultrasonic sound energy density is 2w / ml, and the ultrasonic time is 15min;

[0031] Step 2: Free ammonia pretreatment, add a certain amount of 4mol / L ammonium chloride solution to the sludge, so that the initial ammonia nitrogen concentration in the remaining sludge is 341mg / L, use 4mol / L NaOH solution and 4mol / L The HCl solution adjusted the pH of the remaining sludge to 9 and maintained it for 48 hours, during which the temperature was controlled at 25±0.1°C (under this condition, the initial free ammonia concentration was 150mg / L), and the sludge mechanical stirring speed was 120rpm / min.

[0032] Soluble polysaccharide reaches 439mg / L at 48h after above-mentioned t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com