Technology and apparatus for producing wall sticking prevention multifunctional fertilizer

A technology of production process and production equipment, which is applied in the field of multi-functional fertilizer production process and its equipment, can solve the problems of easy wear of spreader, instability of furnace charge sinking, inconvenient operation of furnace charge, etc., so as to avoid the disconnection of charge and adsorption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

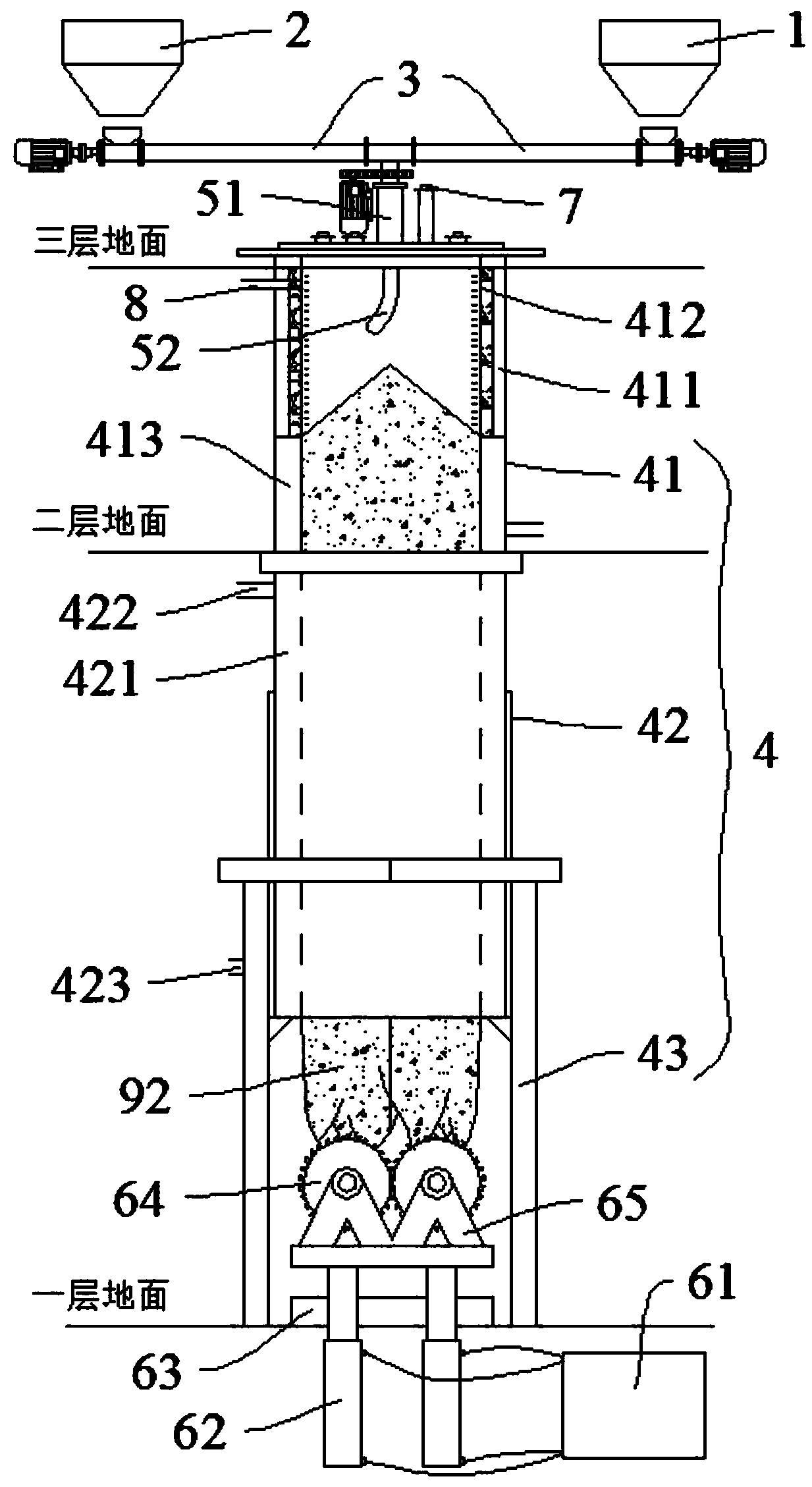

[0044] A kind of anti-adhesive multifunctional fertilizer production process, comprising the following steps:

[0045] Step 1: Crush the calcium carbide with a jaw crusher, mix the crushed calcium carbide 62-68%, fluorite 4-9%, and sodium chloride 8-13%; send the mixed reaction materials to a magnet separator for ferrosilicon separation;

[0046] Step 2: The reaction material after the separation of ferrosilicon in step 1 is crushed by a hammer crusher to a particle size of less than 20 mm, and then sent to a ball mill to be ground to below 80 mesh;

[0047] Step 3: Grinding the returned lime nitrogen powder to below 60 mesh;

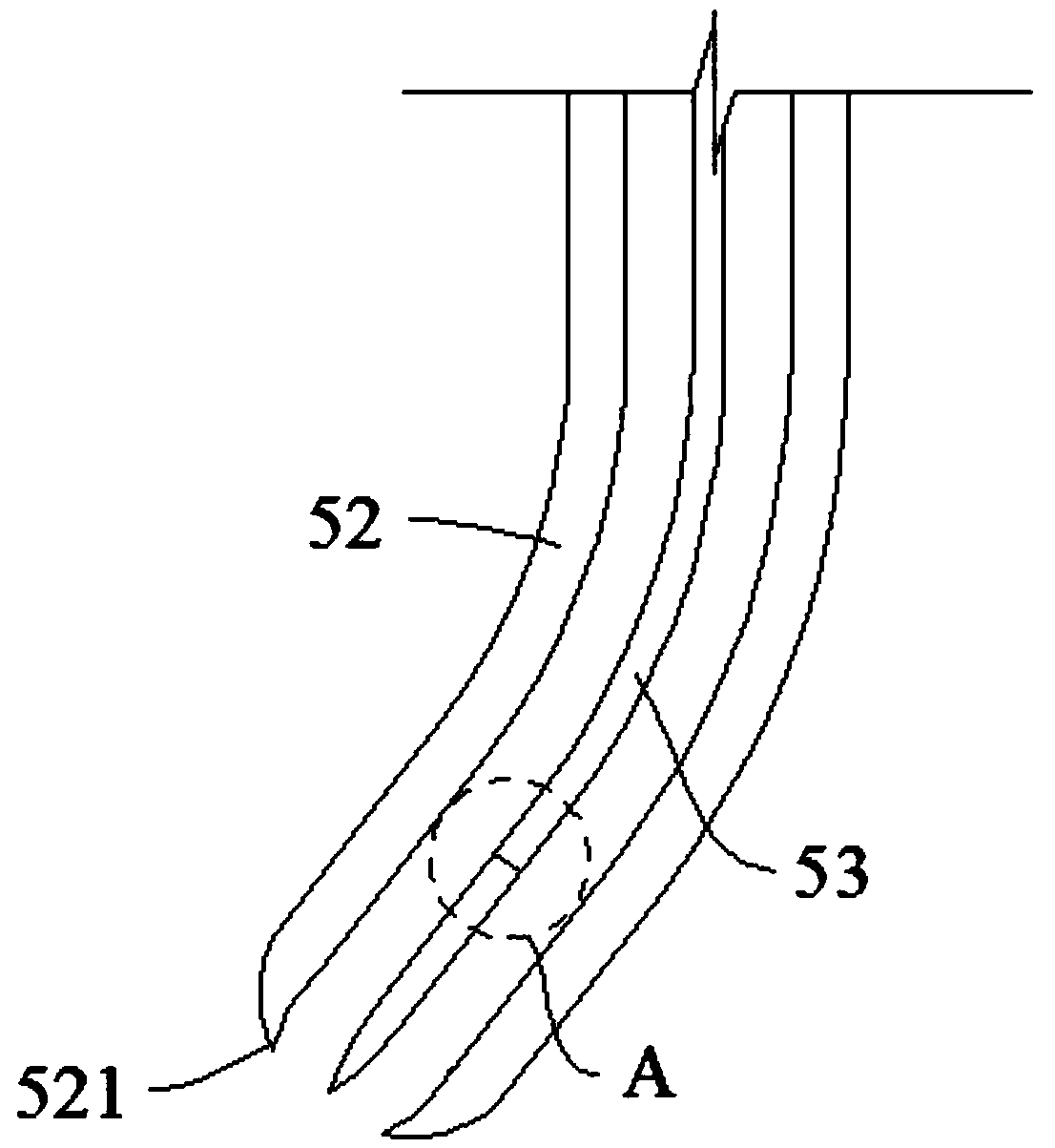

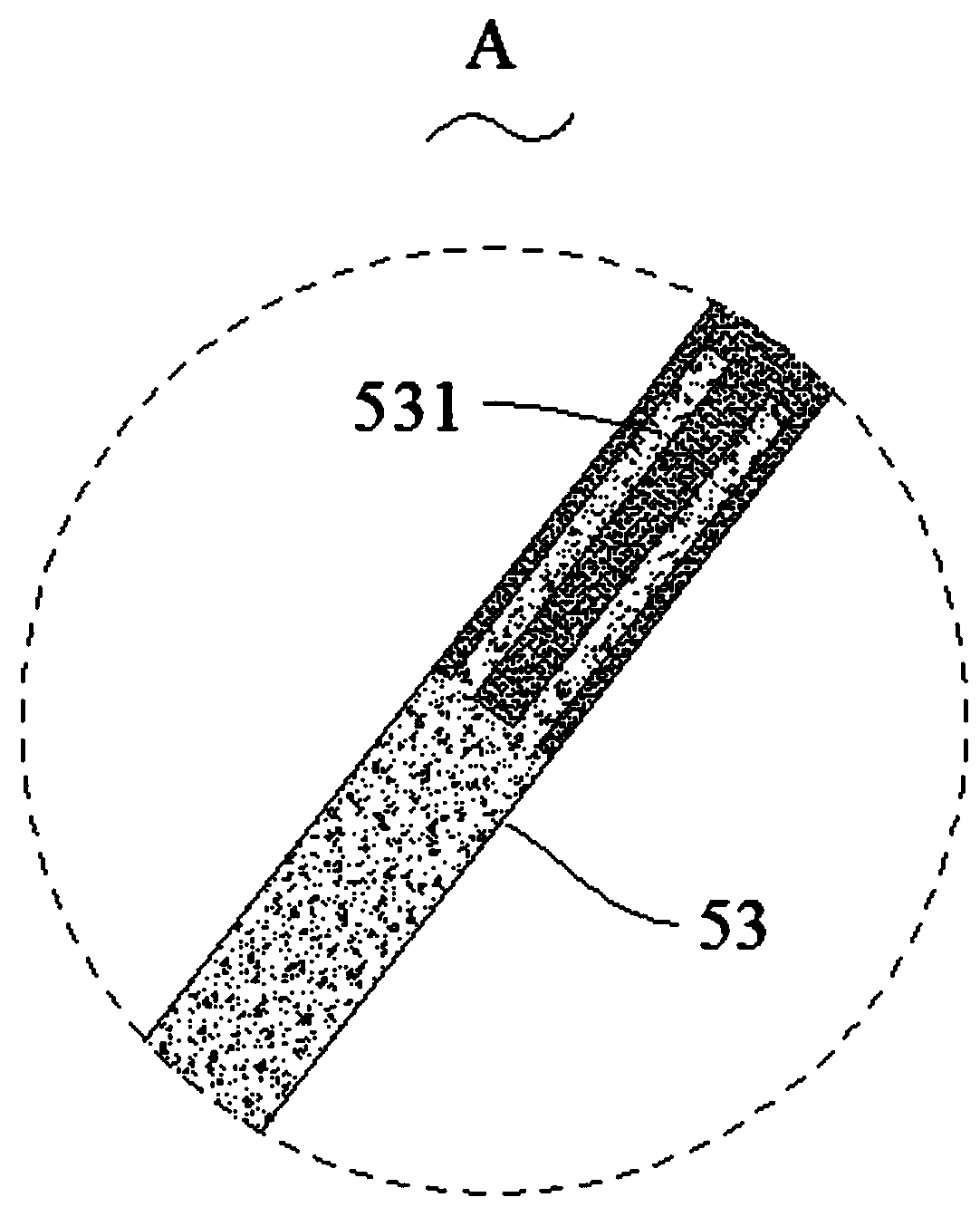

[0048] Step 4: Send the reaction material after step 2 pulverization into reaction bin 1, such as figure 1 As shown, the returned lime nitrogen after step three grinding is sent into the returned furnace hopper 2; the reaction hopper 1 and the returned furnace hopper 2 are communicated with the blanking cavity of the electrostatic generating type feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com