Cationic asphalt emulsifier, preparation method thereof and asphalt emulsifying method

An asphalt emulsifier, emulsified asphalt technology, applied in building components, building insulation materials, construction and other directions, can solve the problems of high price, insufficient emulsifying ability, inability to emulsify SBS modified asphalt, etc., and achieves simple and convenient use and stable emulsifying effect. , Good road performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

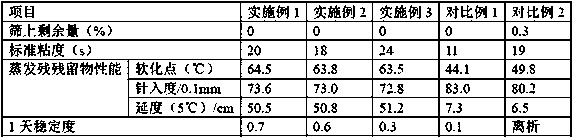

Examples

preparation example Construction

[0026] The invention relates to a cationic asphalt emulsifier, a preparation method of the emulsifier and a method for emulsifying asphalt. The cationic emulsified asphalt emulsified by this emulsifier can be applied to new high-grade asphalt pavement, and can also be used for preventive maintenance of asphalt pavement or cement pavement, maintenance and paving of cold recycled mixture pavement. When used for new asphalt pavement, it is mainly used as the seal layer of the road surface. When used for preventive maintenance and maintenance, it is mainly used for gravel seal layer and slurry seal layer. It can also be used as cold-mix recycled mixture of asphalt pavement recycled materials. The paving of the road.

[0027] The cationic asphalt emulsifier involved in the present invention includes active components, alcohol solvent and inorganic acid, wherein the content of small molecule alcohol solvent is 2-10%, and the content of inorganic acid is 10-50%. Its active component...

Embodiment 1

[0046] Preparation of cationic asphalt emulsifier: 15 grams of C16 fatty acid amide (brand: Beijing Yamei T21), 5 grams of 18 alkyl bis-quaternary ammonium salt (brand: Beijing Yamei AM 77MB), 40 grams of dodecyl dimethyl betaine ( Brand: BS 12), 5 grams of diethylene glycol and 35 grams of phosphoric acid were put into a beaker in sequence, stirred at 80°C for 1 hour, and mixed evenly to obtain a cationic emulsifier.

[0047] Preparation of modified asphalt: Heat Liaohe 90# base asphalt to 160°C, add 3.5% SBS, keep stirring for 60 minutes, and then use colloid mill to grind for 30-90 minutes to make SBS modified asphalt. Keep the SBS modified asphalt at 165~170℃ for later use.

[0048] Preparation of soap liquid: Weigh 10 g of the cationic emulsifier and add it to 490 g of hot water to obtain soap liquid. Keep the temperature of the soap solution at 55-60°C.

[0049] Turn on the colloid mill, add 500g of SBS modified asphalt with a temperature of 165°C and the above soap so...

Embodiment 2

[0051] Preparation of cationic asphalt emulsifier: 18 grams of C18 fatty acid amide (brand: Beijing Yamei T22), 8 grams of 18 alkyl trimethyl ammonium chloride (brand: 1831), 34 grams of cocamidopropyl betaine (brand: CAB 35), 5 grams of diethylene glycol and 35 grams of hydrochloric acid were put into a beaker in sequence, stirred at 80°C for 1 hour, and mixed evenly to obtain a cationic emulsifier.

[0052] Preparation of modified asphalt: heat Liaohe 90# base asphalt to 160°C, add 3.5% SBS, keep stirring for 60 minutes, and then use colloid mill to grind for 30-90 minutes to make SBS modified asphalt. Keep the SBS modified asphalt at 165~170℃ for later use.

[0053] Preparation of soap liquid: Weigh 10 g of the cationic emulsifier and add it to 490 g of hot water to obtain soap liquid. Keep the temperature of the soap solution at 55-60°C.

[0054] Turn on the colloid mill, add 500g of SBS modified asphalt with a temperature of 165°C and the above soap solution into the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com