Prefabricated fiberboard and method for connecting prefabricated fiberboard with composite material profile

A composite material and fiberboard technology, which is applied in building materials, floor slabs, building components, etc., can solve problems such as non-weldability, poor natural bonding performance, and low compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

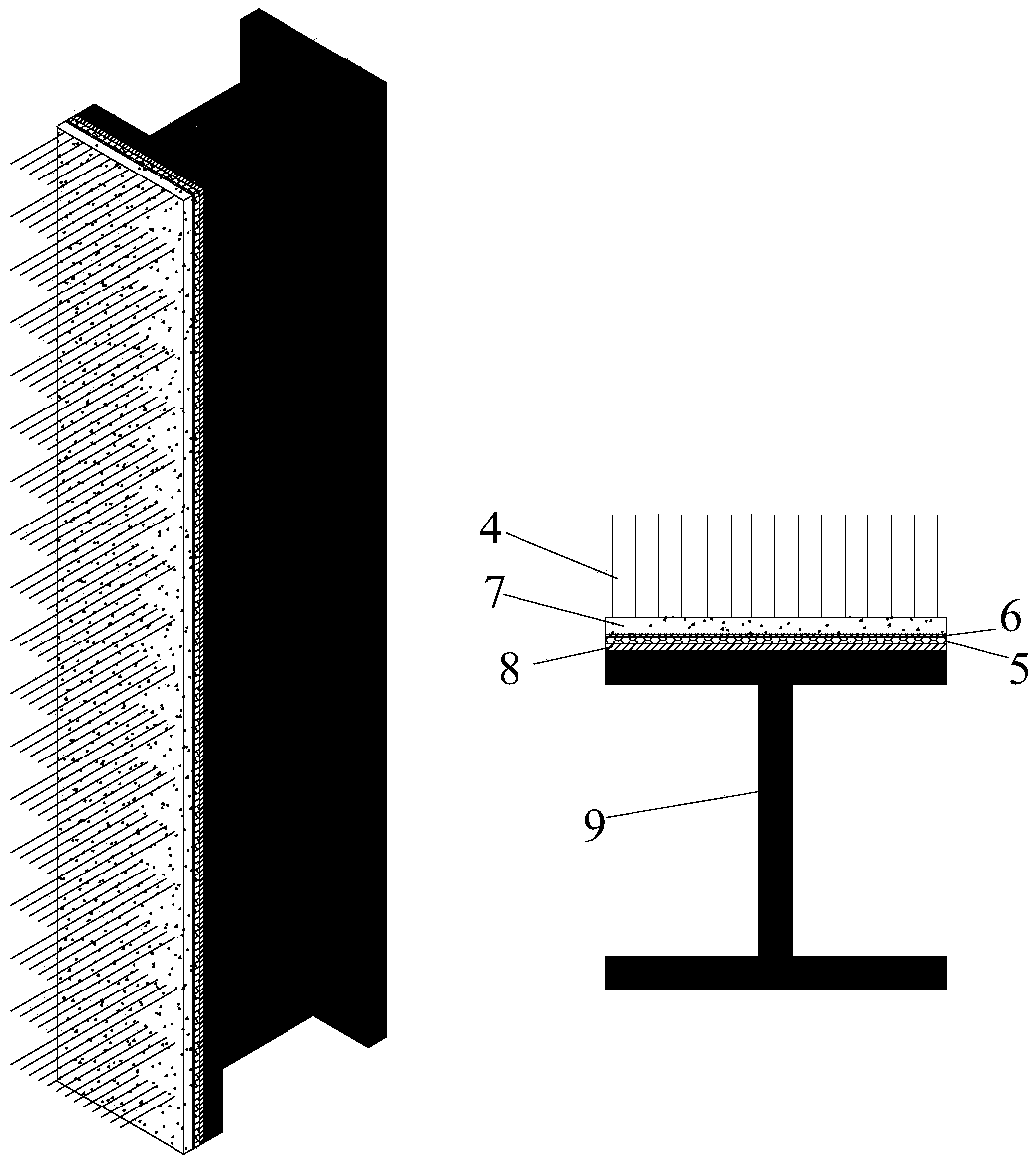

[0024] The present invention provides an anchoring reinforcement technology for fiber-reinforced composite material profiles and concrete. The patent for the invention will be further described below through the description of the drawings and specific implementation methods.

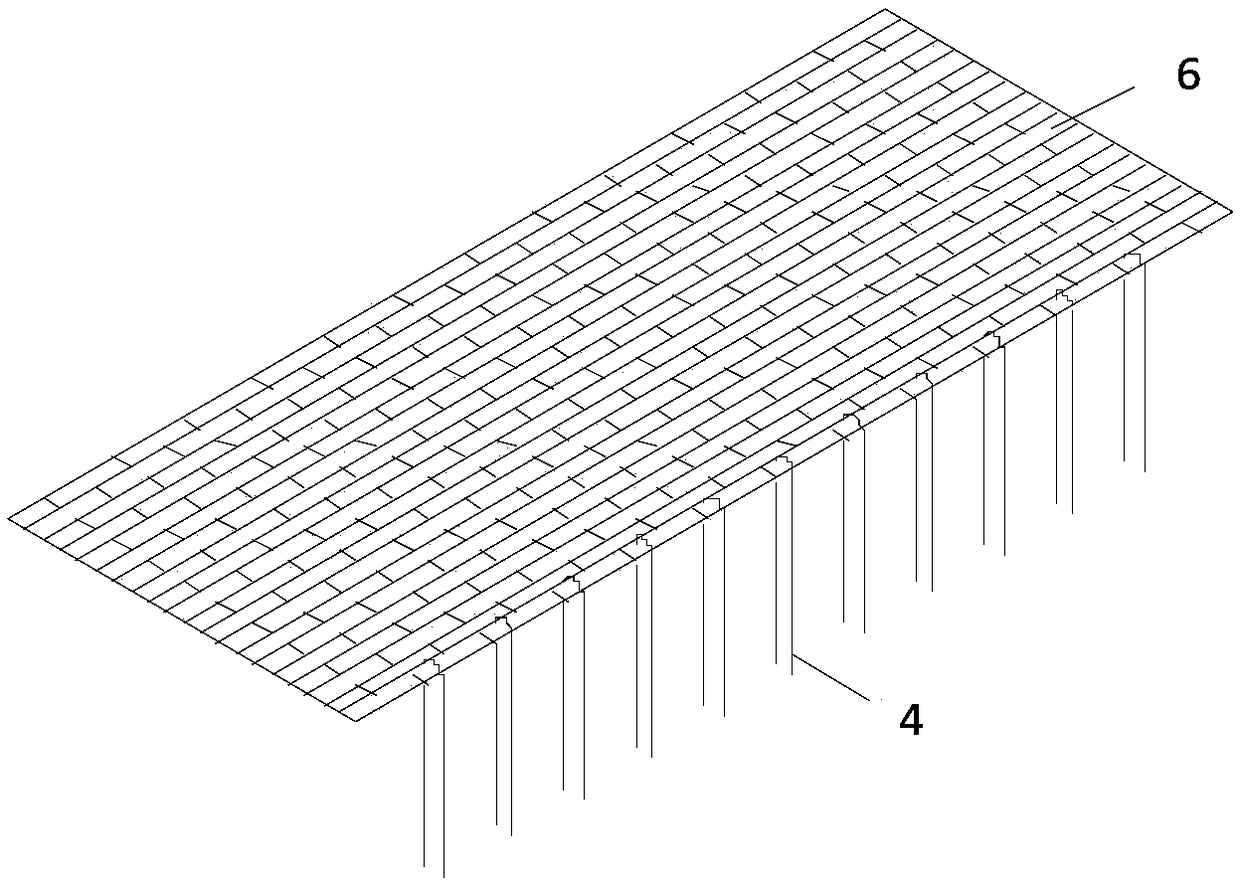

[0025] First, a prefabricated fiberboard proposed according to an embodiment of the present invention will be described with reference to the accompanying drawings.

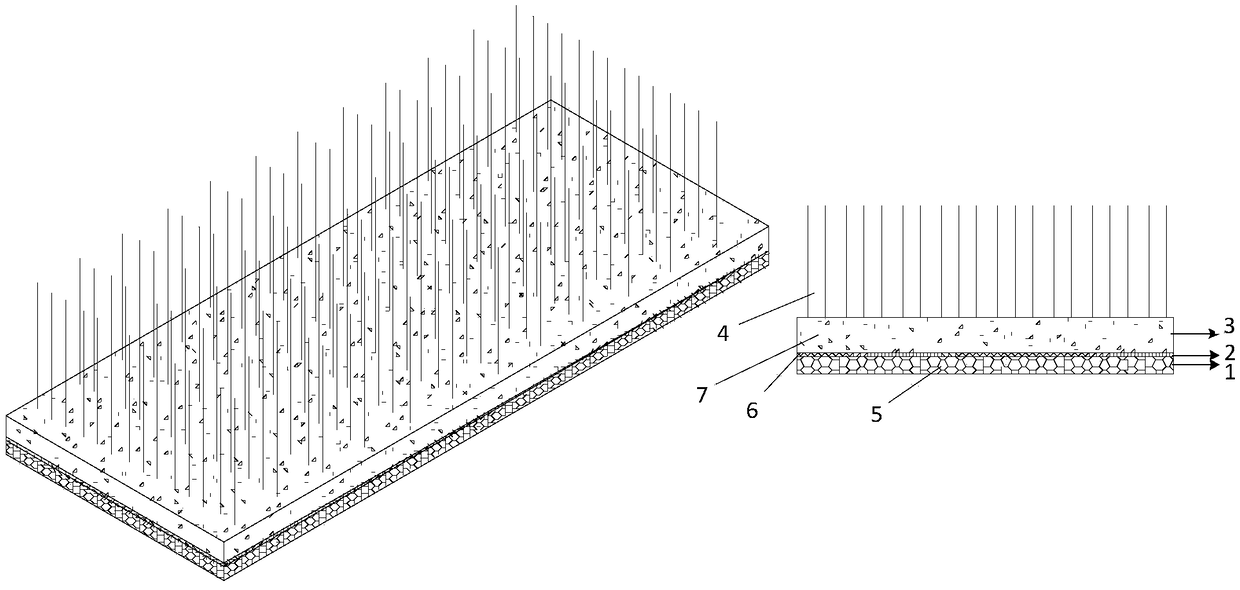

[0026] figure 2 It is a structural schematic diagram of a prefabricated fiberboard according to an embodiment of the present invention.

[0027] Such as figure 2 As shown, the prefabricated fiberboard includes: an epoxy resin adhesive layer 1 , a carbon fiber cloth layer 2 , a mortar-sand mixed layer 3 and a plurality of steel fibers 4 .

[0028] Wherein, an epoxy resin adhesive layer 1 of carbon fiber cloth impregnating adhesive 5 is provided. The carbon fiber cloth layer 2 connected with the epoxy resin adhesive layer 1 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com