Modular geothermal floor

A geothermal floor, modular technology, applied in the direction of floor, covering/lining, building, etc., can solve the problems of geothermal floor thermal conductivity, end cracking, inconsistent drying shrinkage, etc., to improve heat exchange capacity and stress dispersion mode, disperse the stress of the heating surface, and the effect of uniform and stable heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

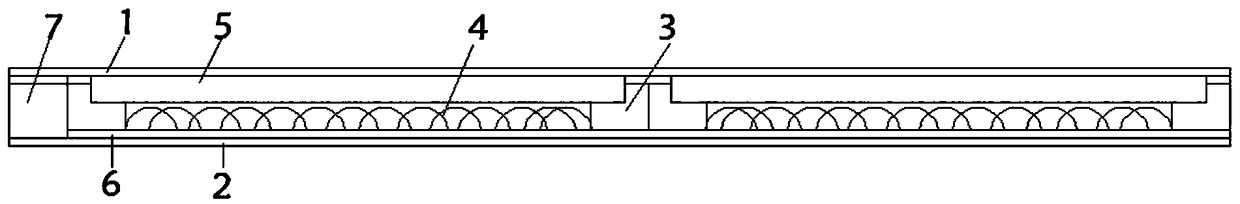

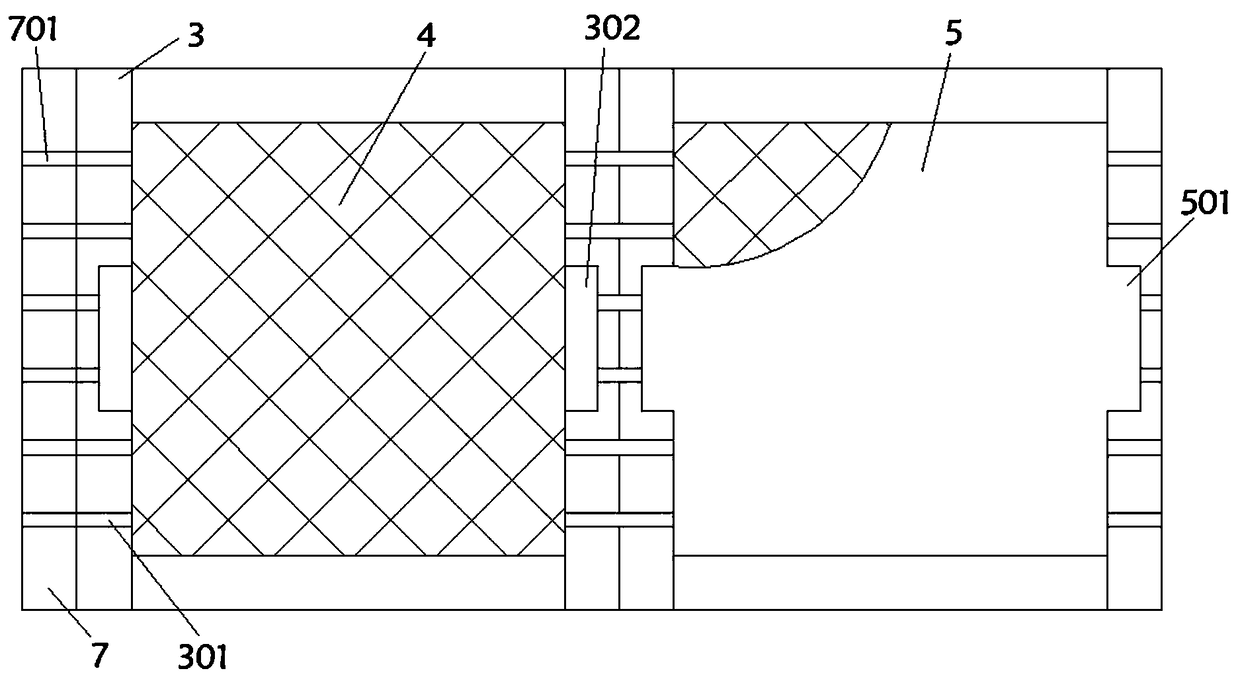

[0029] Such as Figure 1-4 As shown, the modularized geothermal floor of this embodiment includes a bottom plate 2, a base material and a surface plate 1 arranged in sequence from bottom to top. The base material includes a frame bottom plate 6 and several frame units bonded to the frame bottom plate 6. The frame bottom plate 6 and the limiting plate 7 are all bonded on the bottom plate 2, and each frame unit includes a rectangular frame 3, a metal heat conduction mesh 4 arranged at the bottom of the rectangular frame 3, and a cover plate 5 arranged at the top of the rectangular frame 3, as shown in FIG. Plate 1 is glued to the top surface of the cover plate 5 and the top surface of the rectangular frame 3; the length and width of the surface plate 1 and the bottom plate 2 are equal, the width of the frame unit is equal to the width of the bottom plate 2, several frame units and two The sum of the top surface areas of the limiting plate 7 is equal to the top surface areas of t...

Embodiment 2

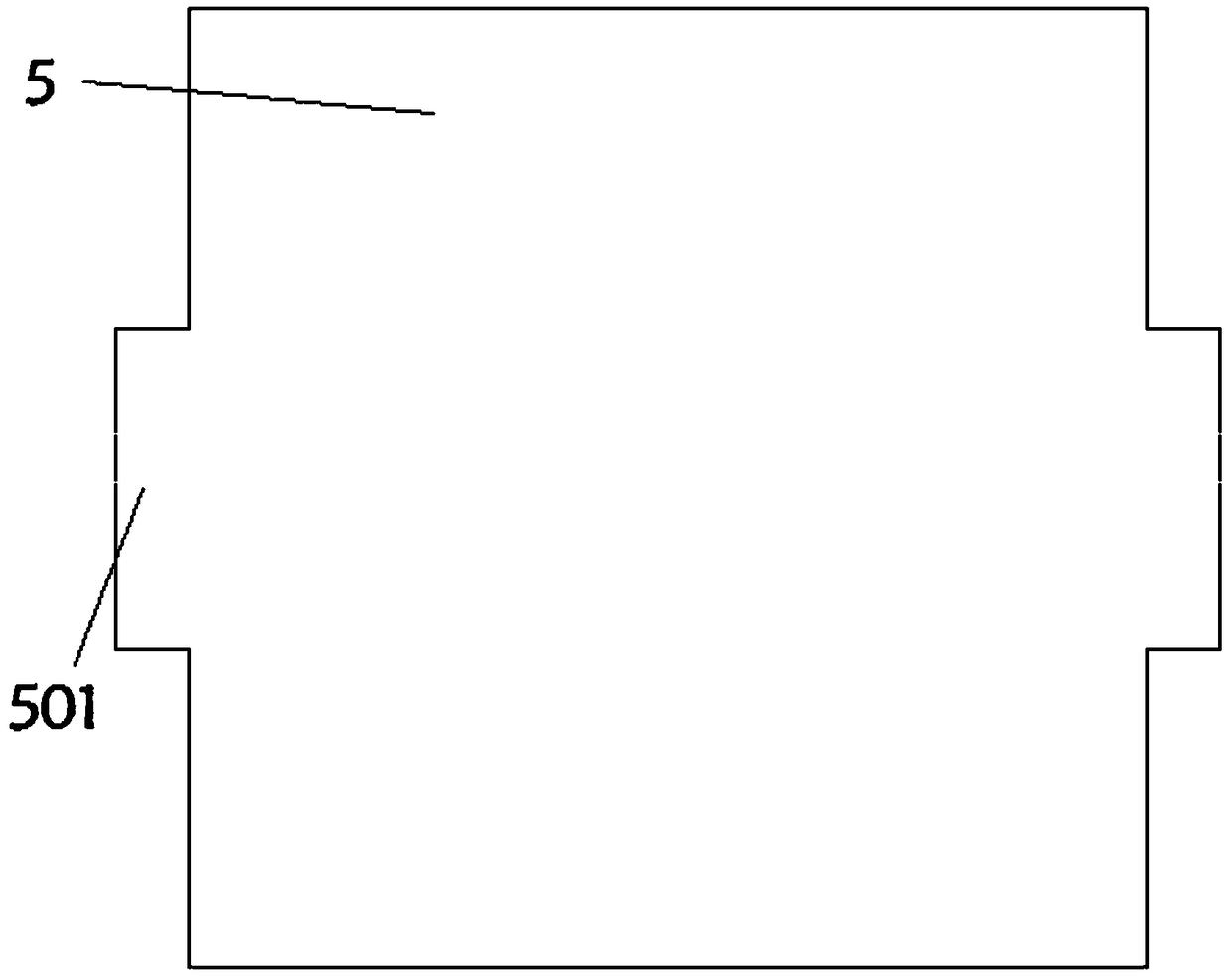

[0036] Such as Figure 5-7 As shown, the modular geothermal floor of this embodiment is basically the same as the modular geothermal floor of Embodiment 1. On the basis of Embodiment 1, the modular geothermal floor of this embodiment also has the following characteristics: the overlapping part of the cover plate 5 501 The overlapping portion 501 is a rectangular plate, the overlapping portion 501 is provided with a groove 502, and the recessed portion 302 is provided with an insertion pin 303 corresponding to the groove 502, and the insertion pin 303 is located in the groove 502, even if the cover plate 5 and The rectangular frame 3 fits in the form of mortise and tenon, which improves the structural stability of the frame unit part; secondly, because the insertion pin 303 is added in the recessed part 302, the width of the recessed part 302 in this embodiment is the same as that of the recessed part 302. The side panels are the same width.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com