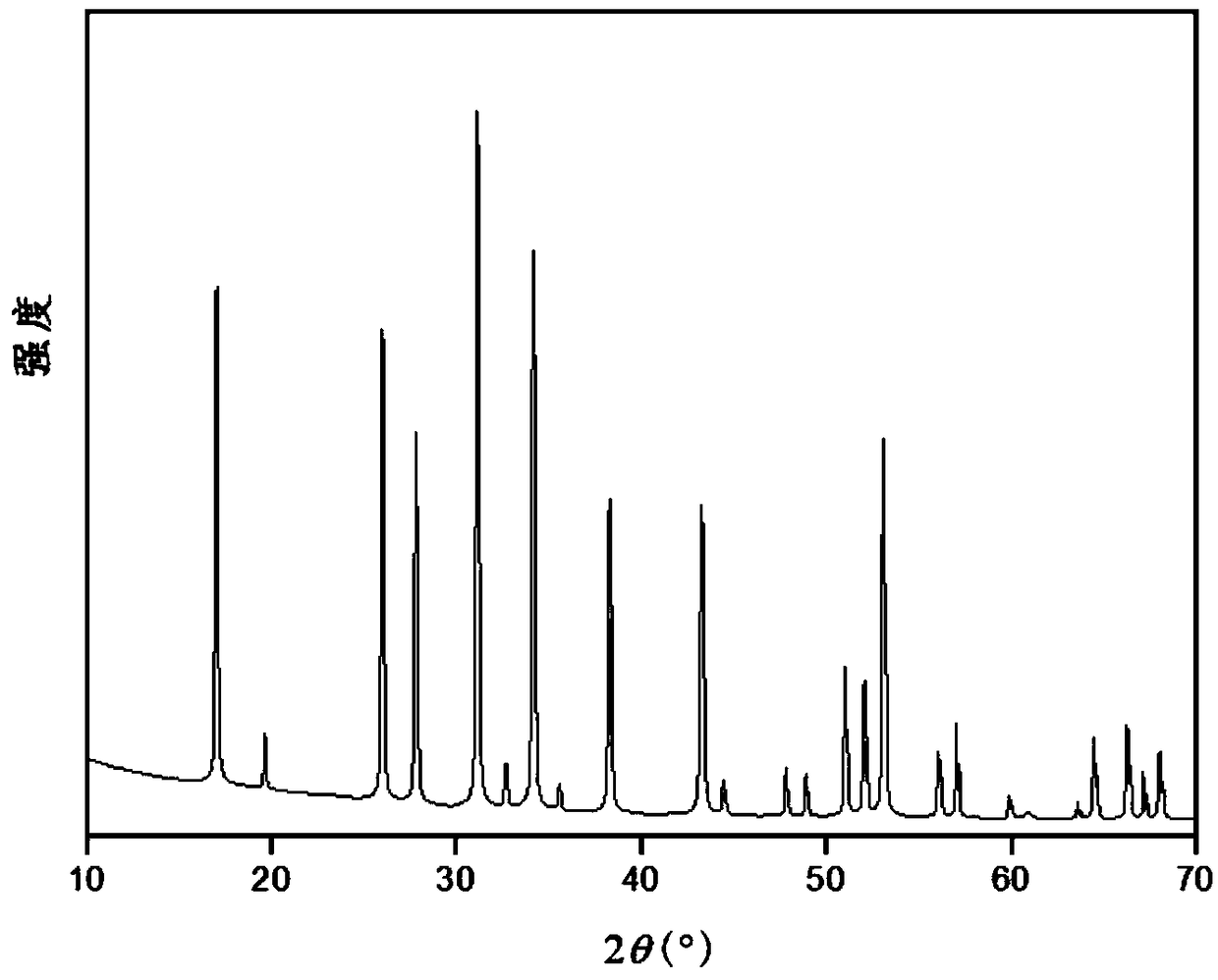

Gallium and molybdenum co-doped garnet type lithium ion solid electrolyte and preparation method thereof

A solid electrolyte, garnet-type technology, applied in the manufacture of electrolyte batteries, electrolytes, non-aqueous electrolyte batteries, etc., can solve the problems of high price and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

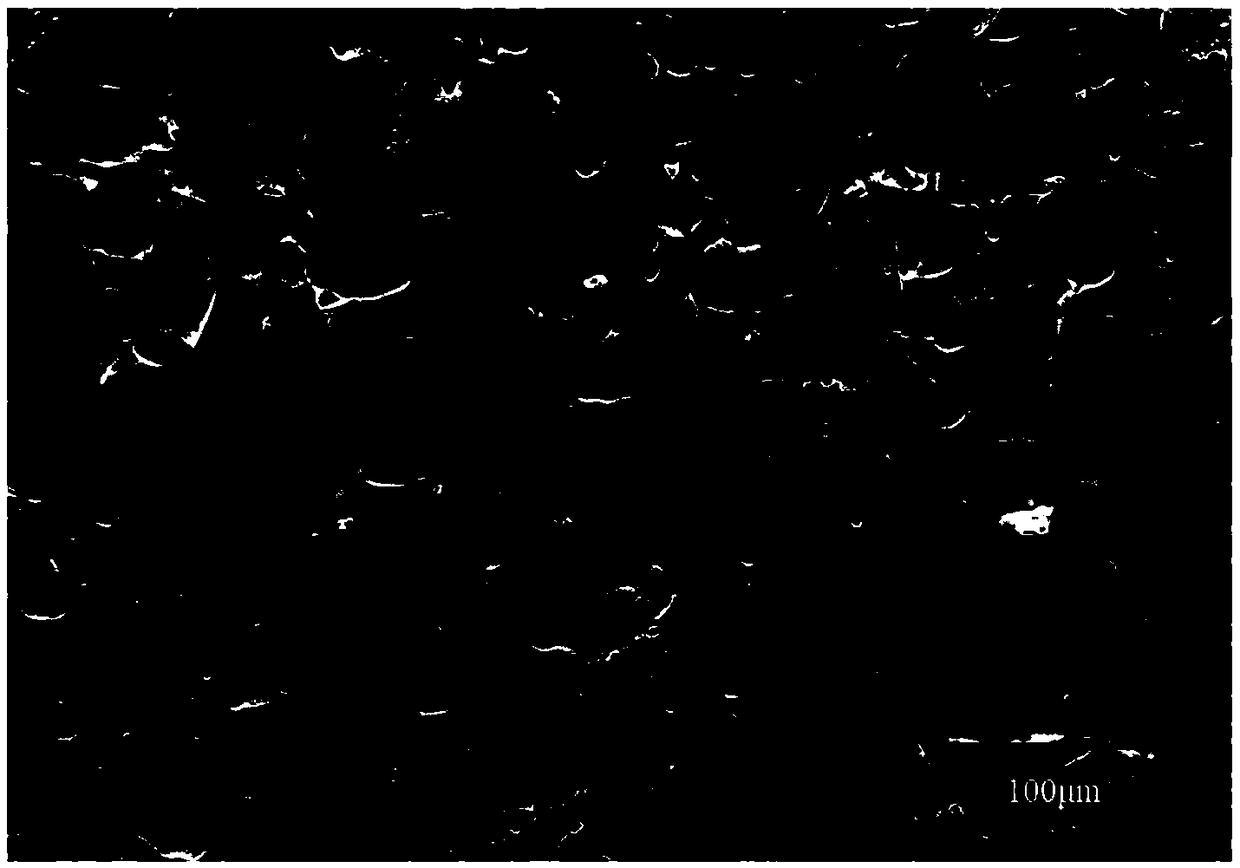

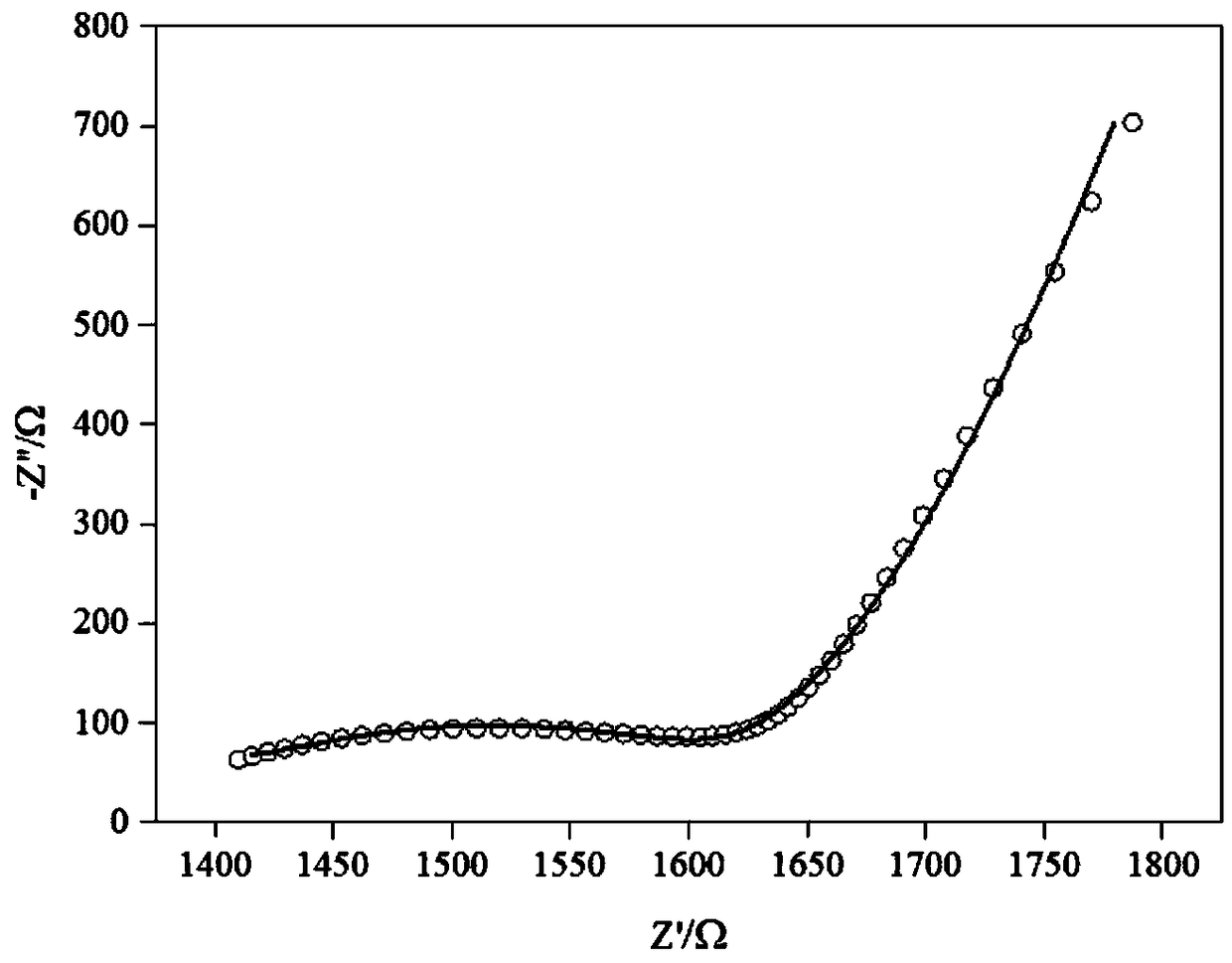

Embodiment 1

[0026] This embodiment provides a method for preparing a garnet-type lithium-ion solid electrolyte co-doped with gallium and molybdenum, which specifically includes the following steps:

[0027] S1, weigh Li respectively 2 CO 3 Powder 10.322g, ZrO 2 Powder 9.36g, Ga 2 o 3 Powder 0.562g, La 2 o 3 Powder 19.548g and MoO 3 Powder 0.576g. Among them, 10.322g of Li 2 CO 3 The powder already contains 10% of the capacity, that is, according to the general chemical formula Li 6.35 Ga 0.15 La 3 Zr 1.9 Mo 0.1 o 12 After determining the mass of each powder, take more Li with a mass fraction of 10%. 2 CO 3 powder.

[0028] Specifically, since Li 2 CO 3 Li produced by powder decomposition 2 O will sublimate at a temperature higher than 1000 ° C, so Li 2 O will sublimate and affect the synthesis of materials, so when batching, take more Li with a mass fraction of 10%. 2 CO 3 The powder is mainly used to make up for the sublimated Li at high temperature during subseque...

Embodiment 2

[0044] This embodiment provides a method for preparing a garnet-type lithium-ion solid electrolyte co-doped with gallium and molybdenum, which specifically includes the following steps:

[0045] S1, weigh Li respectively 2 CO 3 Powder 10.485g, ZrO 2 Powder 9.611g, Ga 2 o 3 Powder 0.562g, La 2 o 3 Powder 19.548g and MoO 3 Powder 0.228g. Among them, 10.458g of Li 2 CO 3 A 10% tolerance is already included in the powder.

[0046] S2. Mix all the powders obtained in step S1 and grind together to form a first material to be molded, and the particle size of the first material to be molded is ≤10 μm.

[0047] Specifically, ball milling was used for grinding. All the powders were put into an agate ball mill jar, absolute ethanol was used as the ball milling solvent, zirconia balls were used as the ball milling medium, and the speed was 650r / min, and ball milling was carried out in a planetary ball mill for 12 hours. After the ball milling, dry at 110° C. to obtain the unifo...

Embodiment 3

[0053] This embodiment provides a method for preparing a garnet-type lithium-ion solid electrolyte co-doped with gallium and molybdenum, which specifically includes the following steps:

[0054] S1, weigh Li respectively 2 CO3 Powder 10.16g, ZrO 2 Powder 9.118g, Ga 2 o 3 Powder 0.562g, La 2 o 3 Powder 19.548g and MoO 3 Powder 0.864g. Among them, 10.16g of Li 2 CO 3 A 10% tolerance is already included in the powder.

[0055] S2. Mix all the powders obtained in step S1 and grind together to form a first material to be molded, and the particle size of the first material to be molded is ≤10 μm.

[0056] Specifically, ball milling was used for grinding. All the powders were put into an agate ball milling jar, absolute ethanol was used as the ball milling solvent, zirconia balls were used as the ball milling medium, and the rotation speed was 400r / min, and ball milling was carried out in a planetary ball mill for 8 hours. After the ball milling, dry at 90° C. to obtain the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ionic conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Ionic conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com