Carbon/carbon composite honeycomb and preparation method thereof

A carbon composite material and honeycomb technology, which is applied in ceramic products, other household appliances, household appliances, etc., can solve the problems of poor thermal stability and unfavorable lightweight requirements in the aerospace field, and achieve short densification cycle and densification process adaptability Excellent, realize the effect of engineering application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The embodiment of the present invention also provides a method for preparing a carbon / carbon composite material honeycomb, comprising the following steps:

[0040] Step 1, preparing a carbon fiber reinforced body of a honeycomb structure, in which the L direction has continuous carbon fibers, and the W direction also has continuous carbon fibers;

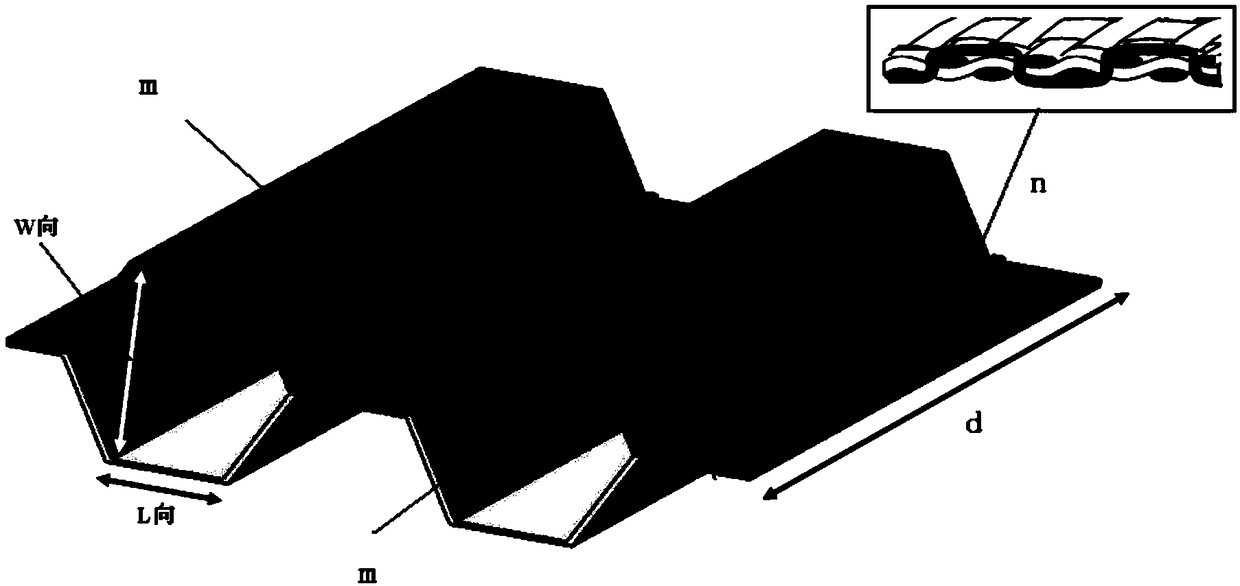

[0041] Specifically, in the embodiment of the present invention, the L-direction and W-direction of the carbon fiber reinforced body honeycomb structure can be realized to have continuous fibers by splicing and sewing carbon cloth, specifically, as figure 2 As shown, the carbon cloth m is first cut into a predetermined shape according to the honeycomb design size and marked at the position to be stitched, and then the two pieces of carbon cloth m are bonded together, and the butt joint surface is stitched by the stitching line n. Insert the mandrel at the seam, and release the mold after solidifying the dimension shape, you ...

Embodiment 1

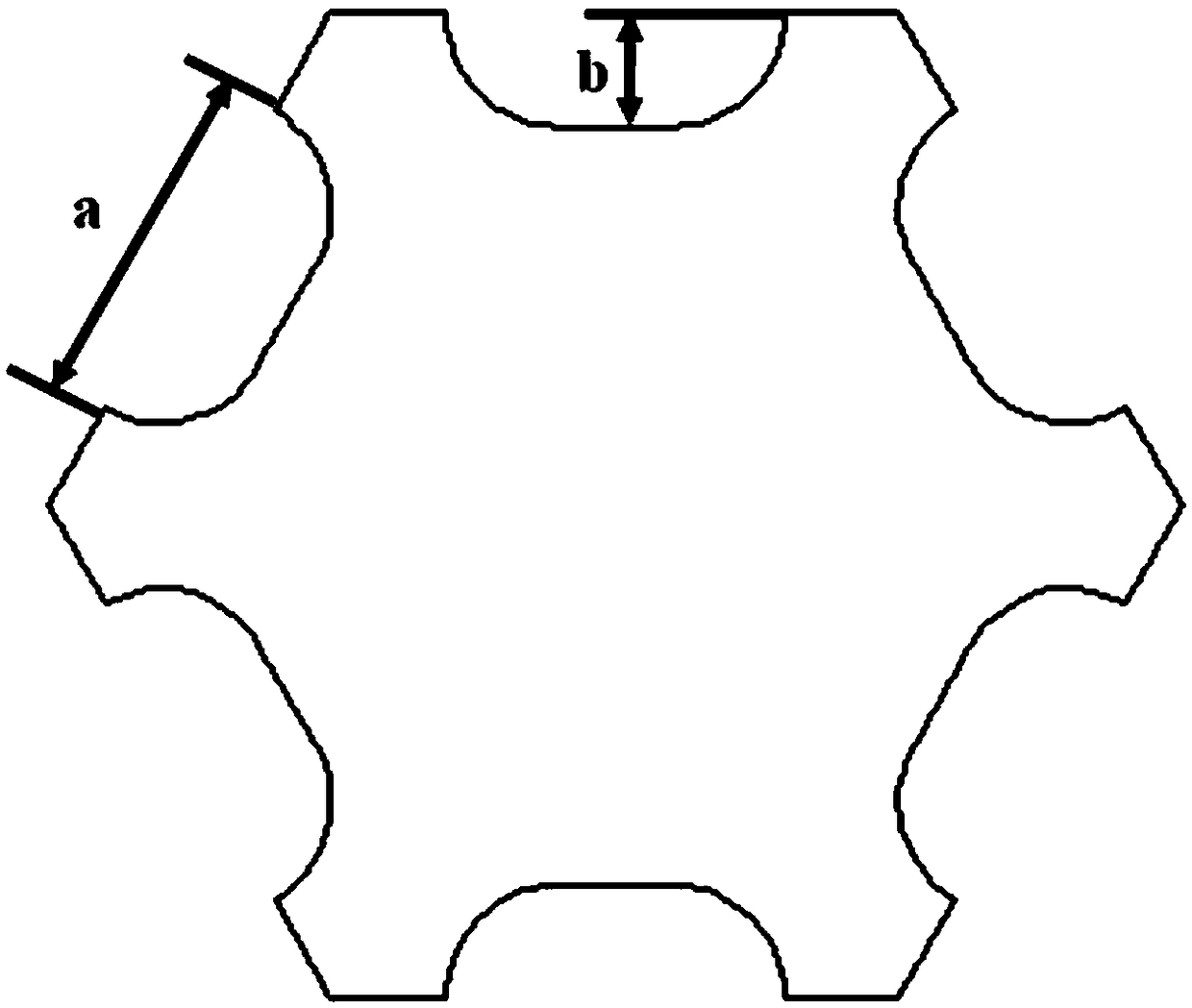

[0053] This embodiment provides a carbon / carbon composite material honeycomb for satellites with an outline size of 200mm×200mm×80mm, a honeycomb cell side length of 5mm, and a honeycomb wall thickness of 0.8mm. The preparation method includes:

[0054] 1) Use general-purpose T300-3K polyacrylonitrile-based carbon fiber to weave to an area density of 240g / cm 3 Plain carbon cloth, warp and weft density 6 threads / cm×6 threads / cm. Then cut the carbon cloth into carbon cloth blocks of a certain specification according to the expanded size of the honeycomb wall; during the cutting process, the warp yarn direction is 0°, rotate counterclockwise to form +45° carbon cloth, and rotate clockwise to form -45° carbon cloth.

[0055] 2) Lay the carbon cloth blocks in step 1) according to the designed layering sequence, and arrange the adjacent carbon cloths in the order of +45 / -45 layering; stitch the carbon cloths in pairs, and stitch the spacing in the thickness direction of the honeyco...

Embodiment 2

[0061] This embodiment provides a carbon / carbon composite material honeycomb with an outline size of 400mm×400mm×80mm, a honeycomb cell side length of 5mm, and a honeycomb wall thickness of 0.8mm. The preparation method includes:

[0062] 1) Use general-purpose T300-3K polyacrylonitrile-based carbon fiber to weave to an area density of 240g / cm 3 Plain carbon cloth, warp and weft density 6 threads / cm×6 threads / cm. Then cut the carbon cloth into carbon cloth blocks of a certain specification according to the expanded size of the honeycomb wall; during the cutting process, the warp yarn direction is 0°, rotate counterclockwise to form +45° carbon cloth, and rotate clockwise to form -45° carbon cloth.

[0063] 2) Lay the carbon cloth blocks in step 1) according to the designed layering sequence, and arrange the adjacent carbon cloths in the order of +45 / -45 layering; stitch the carbon cloths in pairs, and stitch the spacing in the thickness direction of the honeycomb 4mm, the st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com