Evaluation method for catalytic hydrolysis performance of protease on chrome tanned collagen fiber

A technology for tanning collagen and catalyzing hydrolysis is applied in the field of catalytic hydrolysis performance evaluation and activity determination of chrome tanned collagen fibers by protease, which can solve the problem of lack of functional performance in the selection of wet blue leather enzyme softening technology and the blindness of control of softening conditions, etc. problems, to achieve the effect of flexible test methods and easy promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

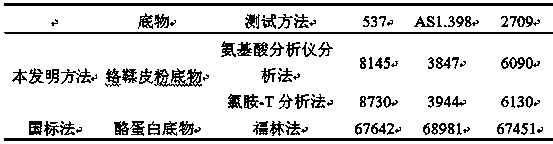

[0033]Example 1——Catalytic hydrolysis performance evaluation and activity determination of different types of proteases on chrome-tanned collagen fibers

[0034] (1) Preparation of reagents

[0035] Prepare 0.1mol / L Braytan-Robinson buffer solution (B-R buffer solution): Weigh 6.183g boric acid and dissolve it in an appropriate amount of distilled water, add 11.529g phosphoric acid and 6.005g acetic acid, and dilute to 1L with distilled water, then use 4mol / L of NaOH solution to adjust the pH to 3.0, 7.0 or 9.0, respectively.

[0036] Prepare 0.08 g / mL NaCl solution: Weigh 0.5 g NaCl, dissolve it in distilled water and dilute to 100 mL.

[0037] Protease 537 was dissolved with pH 3.0 B-R buffer and diluted 100 times, and the supernatant was taken after centrifugation to obtain 537 enzyme solution; Protease AS1.398 was dissolved and diluted 100 times with pH 7.0 B-R buffer, and the supernatant was taken after centrifugation The supernatant was obtained as the AS1.398 enzyme ...

Embodiment 2

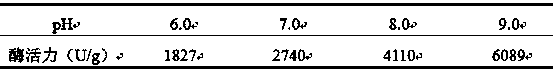

[0049] Example 2—Evaluation of catalytic hydrolysis performance and activity determination of alkaline protease 2709 on chrome-tanned collagen fibers under different pH conditions

[0050] The preparation of the chrome-tanned leather powder substrate, the determination of the concentration of hydroxyproline in the digestion solution and the calculation method of the enzyme activity are the same as those in Example 1, and the determination of the concentration of hydroxyproline uses the analysis method of an amino acid analyzer. The preparation of the reagents and the preparation of the reaction solution to be tested and the blank control solution are as follows:

[0051] (1) Preparation of reagents

[0052] Prepare 0.1mol / L Braytan-Robinson buffer solution (B-R buffer solution): Weigh 6.183g boric acid and dissolve it in an appropriate amount of distilled water, add 11.529g phosphoric acid and 6.005g acetic acid, and dilute to 1L with distilled water, then use 4mol / L of NaOH...

Embodiment 3

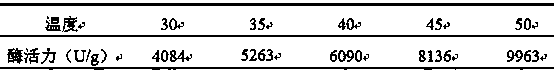

[0061] Example 3—Evaluation of catalytic hydrolysis performance and activity determination of alkaline protease 2709 on chrome-tanned collagen fibers under different temperature conditions

[0062] The preparation of the reagents, the preparation of the chrome-tanned leather powder substrate, the determination of the concentration of hydroxyproline in the digestion solution and the calculation method of the enzyme activity are the same as in Example 2, and the pH of the selected B-R buffer is 9.0. The steps for preparing the reaction solution to be tested and the blank control solution are as follows:

[0063] Weigh 5 parts of 100 mg chrome tanned leather powder as the substrate, add 5 mL of B-R buffer solution with pH 9.0, mix well, heat to 30, 35, 40, 45 and 50°C respectively, then add 1 mL of the Enzyme solution, in a water bath constant temperature oscillator under shaking conditions at 30, 35, 40, 45 and 50 ° C enzymolysis reaction for 4 hours, at this time the chrome tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com