Method for improving first piece effect in plasma etching process

A plasma and process technology, which is applied in the field of first-piece effect in the plasma etching process, and can solve the problems of excessive cleaning, poor filling process, large angle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

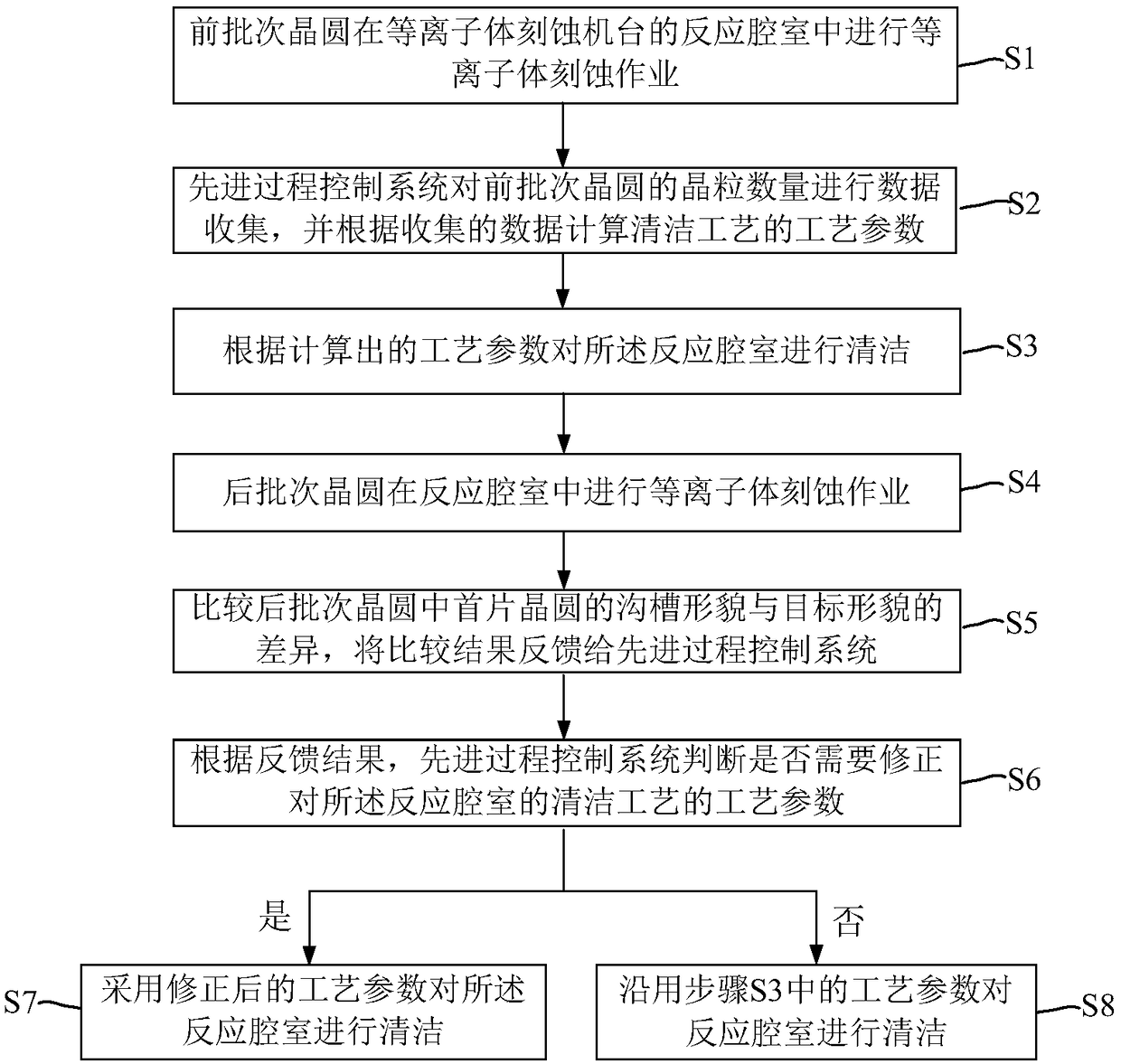

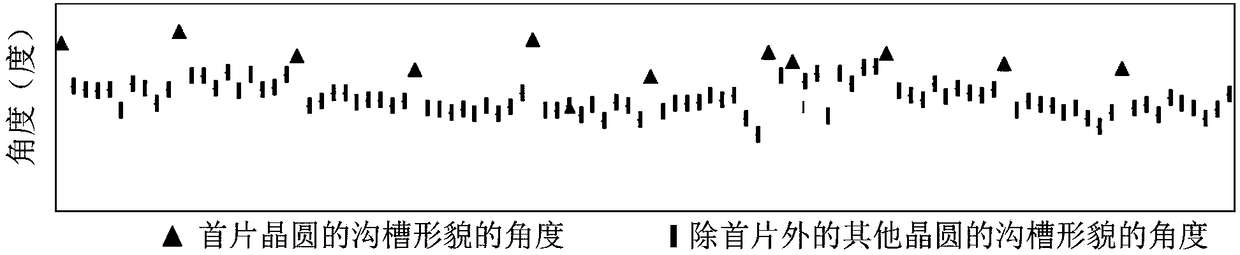

Method used

Image

Examples

Embodiment Construction

[0017] As the process window for wafer processing is getting smaller and smaller, stricter process control requirements are imposed on manufacturers of integrated circuit equipment and inspection equipment. The previous statistical process control and the control method of a certain parameter alone cannot meet the current technological requirements. In order to improve the production efficiency of the equipment, make the process production line have extensibility and flexibility, and improve the product quality and continuity, advanced process control has increasingly attracted people's attention and research.

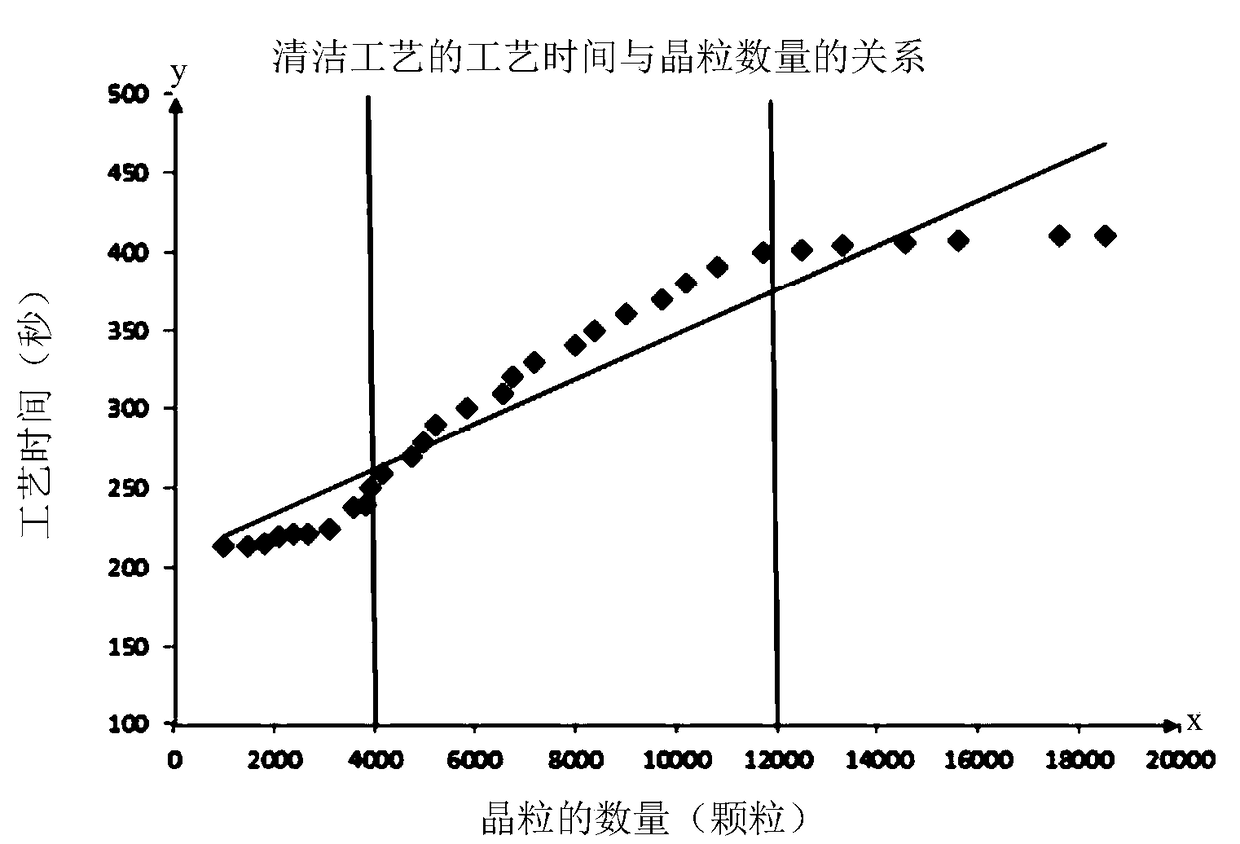

[0018] As described in the background art, the source of the polymer in the reaction chamber is: during the plasma etching of the wafer, the microstructure containing the low-k dielectric material needs to be cleaned, usually using carbon dioxide (CO 2 ) or oxygen (O 2 ) as a reactive gas, whereas CO 2 A side effect of photoresist lift-off is the carbon-rich product,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com