Sweet corn molar rod and preparation method thereof

A molar stick, sweet corn technology, applied in baking, baked goods with modified ingredients, dough processing and other directions, can solve problems such as inability to alleviate, unable to provide proper nutrition, etc., to reduce the degree of denaturation, reduce baking time, and mature consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

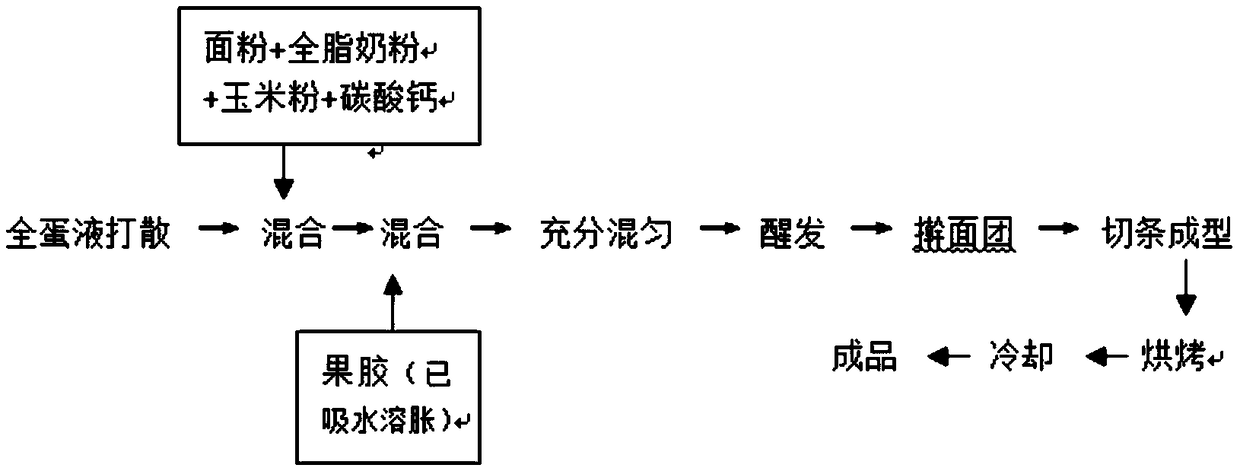

[0037] Sweet corn molar stick manufacturing process of the present invention comprises the following steps:

[0038] Raw material preparation:

[0039] 1) Sweet corn flour: grind corn granules with a Chinese herbal medicine grinder to obtain sweet corn flour that can pass through a 150-mesh sieve.

[0040] 2) Raw material weighing: Take 100g of low-gluten flour, 20g of whole milk powder, 50g of sweet corn flour, 44g of whole egg liquid, 13.6g of pectin, and 29g of water. The powder can pass through 80 mesh sieve.

[0041] Step 1) Dissolve the pectin in pure water at 80°C, stir well with a glass rod to make it fully swell and then dissolve, and bathe in hot water for 1 hour.

[0042] Step 2) Mixing: beat the whole egg liquid into a container, sieve into 1 / 3 of the evenly mixed powder, cut and mix evenly; add pre-soaked pectin, sieve in 1 / 3 of the powder, cut and mix evenly, sieve Add the remaining powder and knead the dough until it becomes smooth.

[0043] Step 3) proofing...

Embodiment 2

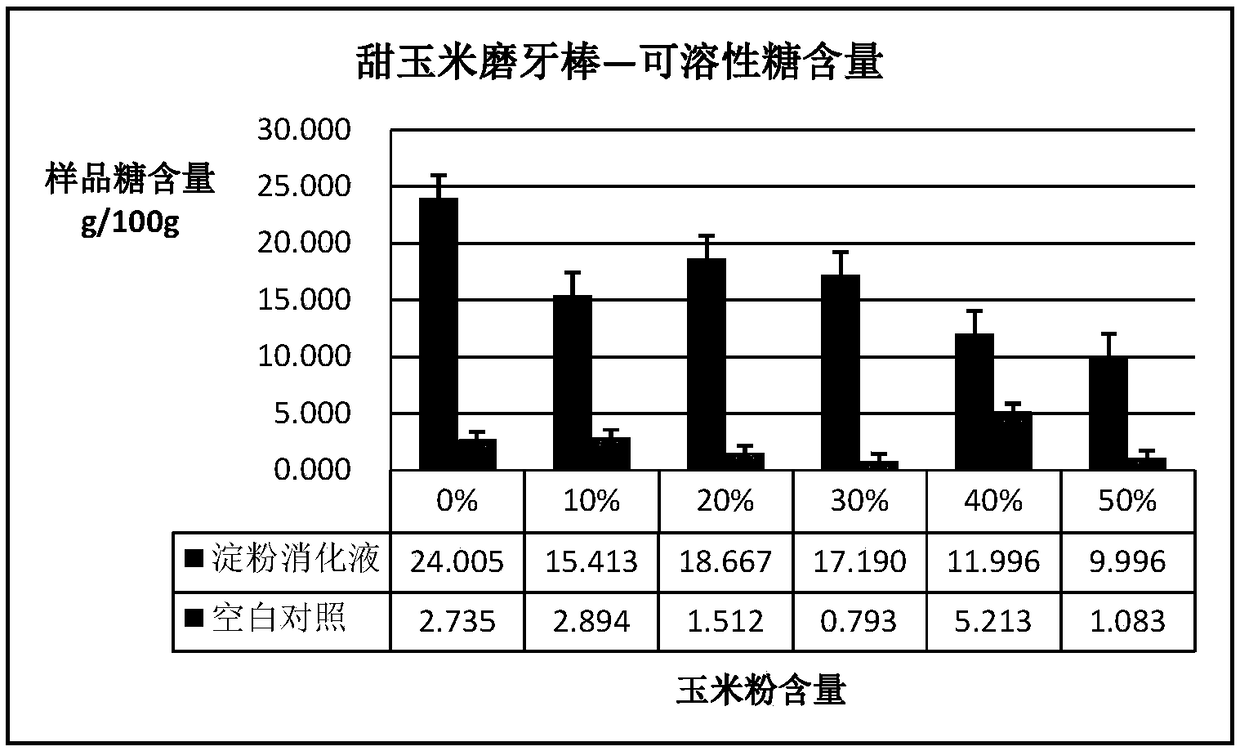

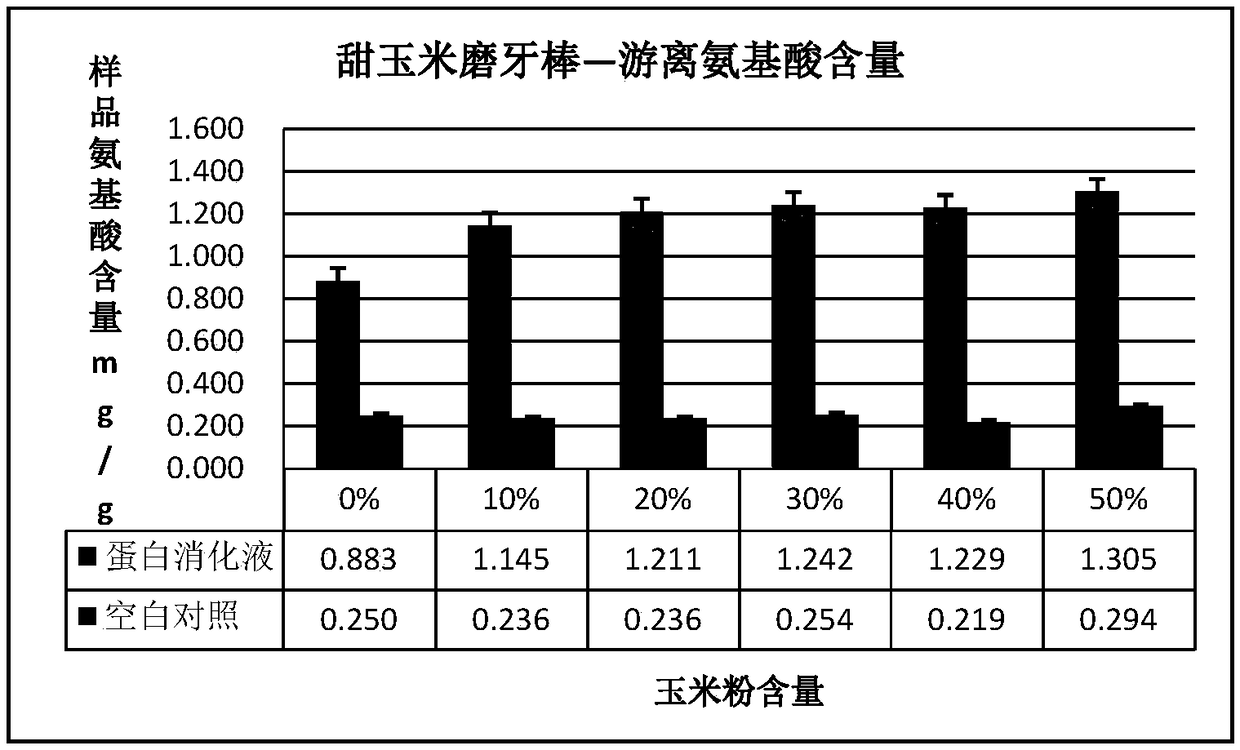

[0048] In vitro enzymatic digestion performance experiment of sweet corn molar sticks

[0049] Starch digestion: Weigh 2g crushed sample, add 20 mL of water and 500μL of α-amylase / calcium chloride solution (32.5mg of α-amylase dissolved in 25mL of 1mmol / L calcium chloride, pH 7.0 ), mix well, and incubate at 37°C for 2h with shaking.

[0050] Protein digestion: Weigh 2 g of the pulverized sample, add 20 mL of dilute hydrochloric acid solution with pH 2.0 and 0.1 g of pepsin (pepsin can be prepared in the hydrochloric acid solution in advance), mix well, and incubate at 37°C for 2 hours with shaking.

[0051] Lipid digestion: Weigh 2 g of crushed sample and add 15 mL of NaHCO with pH 7.4 3 solution (0.9M) and 5 mL of pancreatin-bile salt mixture (0.1 g of pancreatin / trypsin and 0.625 g of bile salts were dissolved in 25 mL of 0.1 mol / L NaHCO 3 solution), mix thoroughly, and incubate at 37°C for 2 h with shaking.

[0052] Blank control group: Weigh 2 g of pulverized samples,...

Embodiment 3

[0056] Sweet corn molar stick manufacturing process of the present invention comprises the following steps:

[0057] Raw material preparation:

[0058] 1) Sweet corn flour: grind corn granules with a Chinese herbal medicine grinder to obtain corn flour that can pass through a 200-mesh sieve.

[0059] 2) Raw material weighing: Take 100g of low-gluten flour, 25g of whole milk powder, 20g of sweet corn flour, 40g of whole egg liquid, 14g of pectin, and 27g of water. The powder can pass through 80 mesh sieve.

[0060] Step 1) Dissolve the pectin in pure water at 80°C, stir well with a glass rod to make it fully swell and then dissolve, and bathe in hot water for 75 minutes.

[0061] Step 2) Mixing: beat the whole egg liquid into a container, sieve into 1 / 3 of the evenly mixed powder, cut and mix evenly; add pre-soaked pectin, sieve in 1 / 3 of the powder, cut and mix evenly, sieve Add the remaining powder and knead the dough until it becomes smooth.

[0062] Step 3) Proofing: Wr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com