Loaded type graphite phase like carbon nitride photocatalyst and application thereof to photocatalytic degradation of formaldehyde

A technology of graphite phase carbon nitride and phase carbon nitride light, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of unobvious degradation efficiency and achieve broad application prospects and Market value, simple preparation method, good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

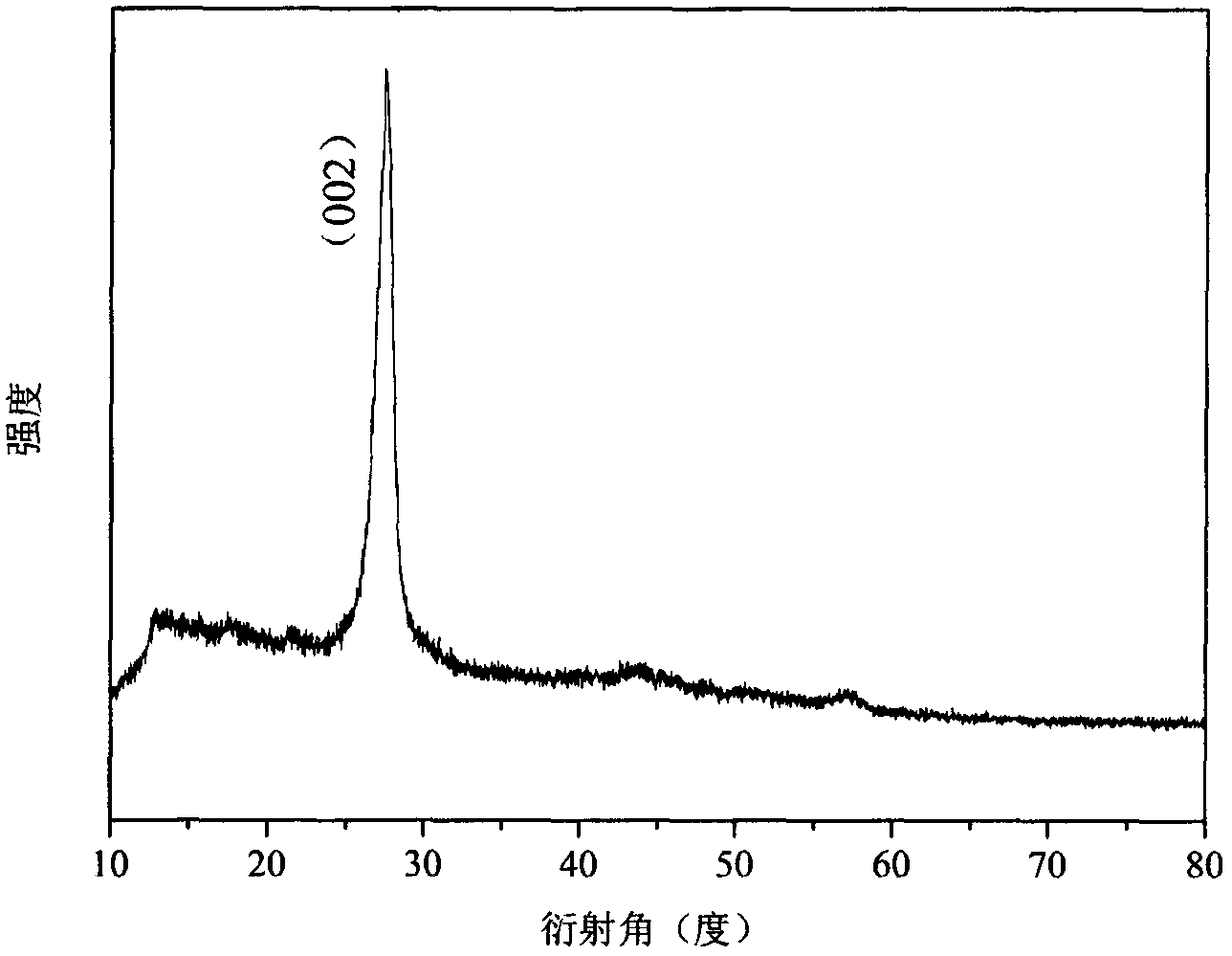

[0025] 1) Weigh 10g of urea and put it in a crucible with a lid.

[0026] 2) Put the crucible in a muffle furnace, raise the temperature from room temperature to 550°C at a heating rate of 2°C / min and keep it warm for 2 hours, and then cool down to room temperature naturally.

[0027] 3) After the reaction, weigh and grind the obtained sample.

Embodiment 2

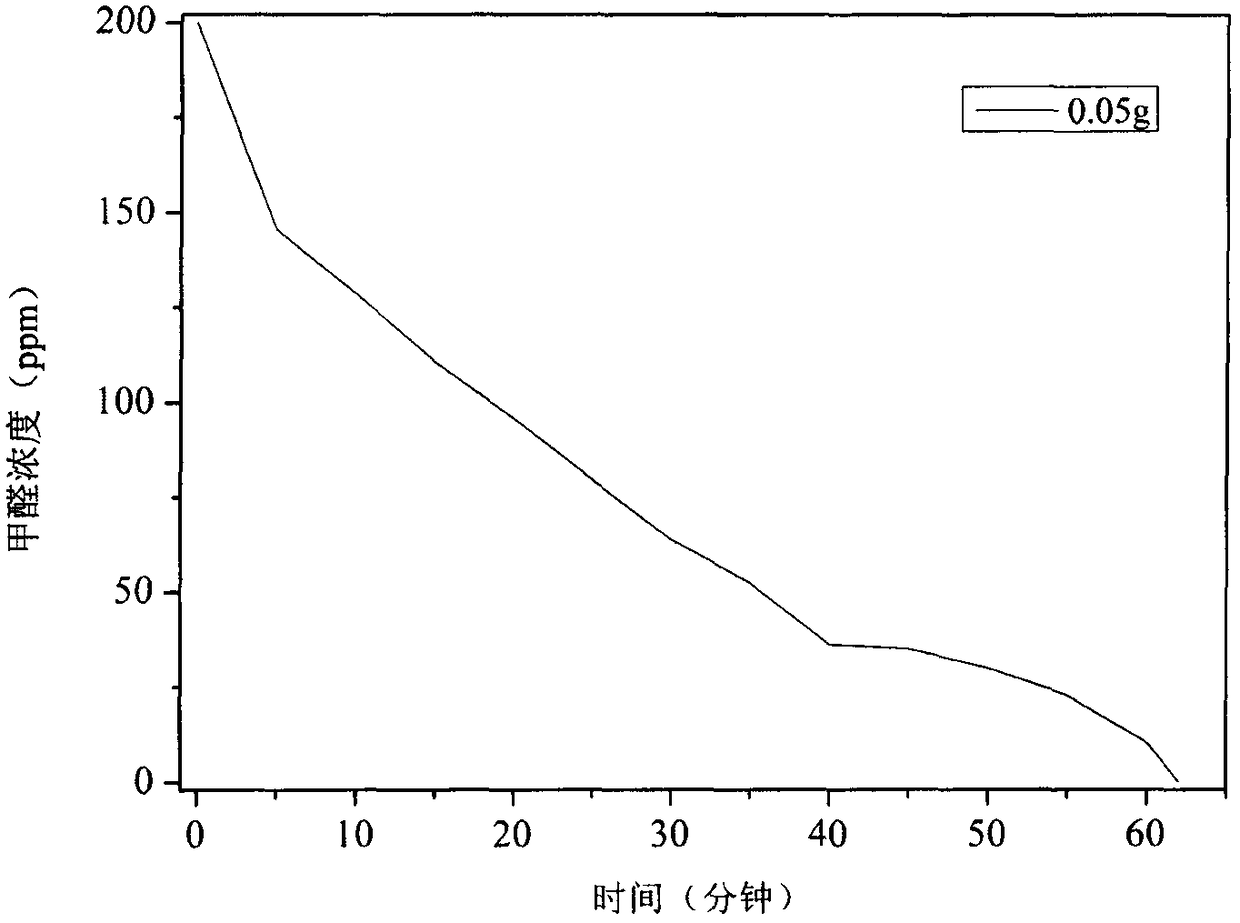

[0029] 1) Weigh 0.05 g of the prepared graphite-like carbon nitride powder with an electronic balance.

[0030] 2) Measure 200ml of distilled water and put it in a beaker. Put the weighed graphite-like carbon nitride in water, stir it evenly, put it into the bracket, and arrange the glass fiber on the bracket, so that the glass fiber cloth is in the center of the solution, and stir for 24 hours to make it evenly loaded.

[0031] 3) Put the glass fiber cloth loaded with graphite-like carbon nitride into an oven, and dry at 110° C. to obtain the glass fiber cloth loaded with graphite-like carbon nitride.

Embodiment 3

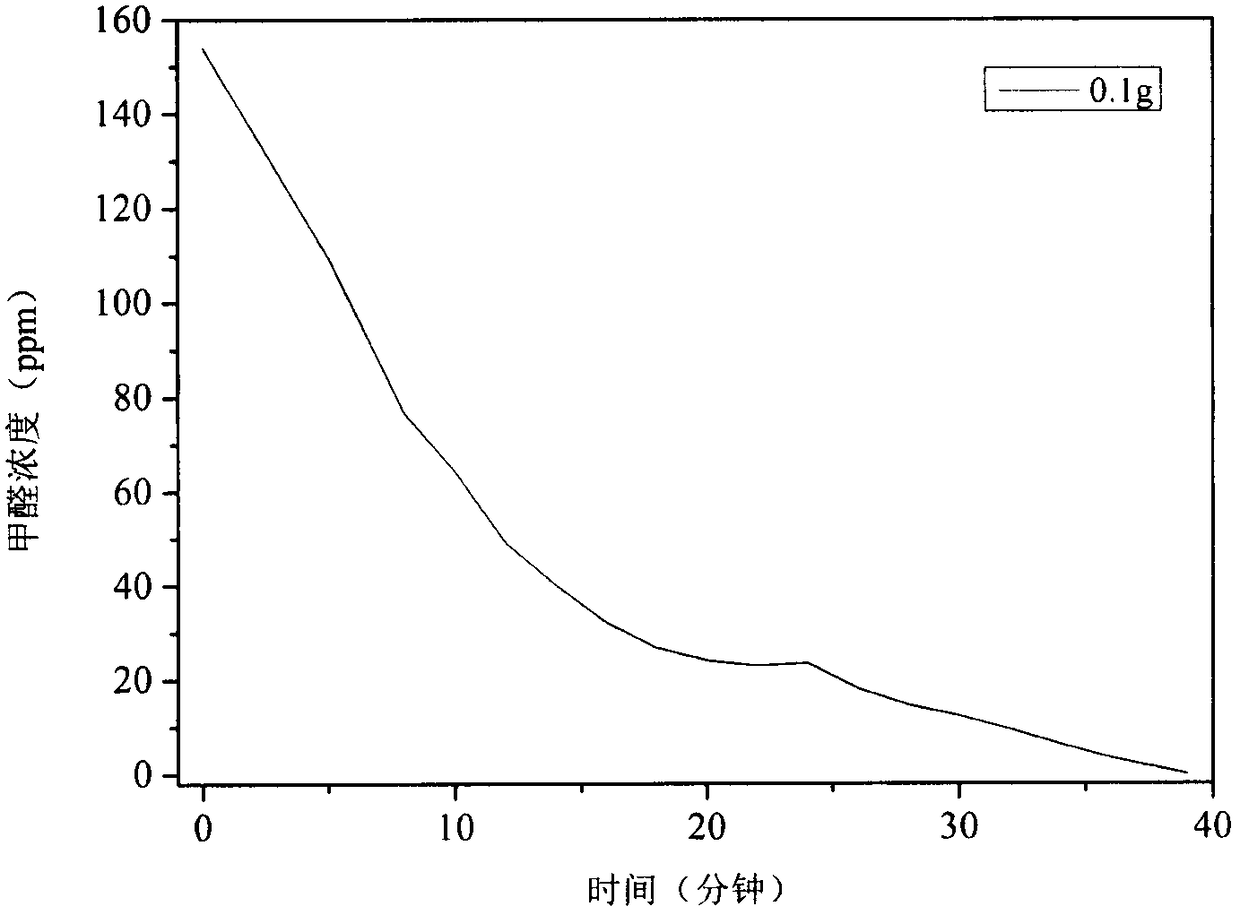

[0033] 1) Weigh 0.10 g of the prepared graphite-like carbon nitride powder with an electronic balance.

[0034] 2) Measure 200ml of distilled water and put it in a beaker. Put the weighed graphite-like carbon nitride in water, stir it evenly, put it into the bracket, and arrange the glass fiber on the bracket, so that the glass fiber cloth is in the center of the solution, and stir for 24 hours to make it evenly loaded.

[0035] 3) Put the glass fiber cloth loaded with graphite-like carbon nitride into an oven, and dry at 110° C. to obtain the glass fiber cloth loaded with graphite-like carbon nitride.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com