Self-gravity hydrodynamic cavitation and ultraviolet radiation combined ballast water treatment device

A technology of ultraviolet radiation and hydraulic cavitation, applied in water/sewage treatment, natural water treatment, heating water/sewage treatment, etc., can solve the range and degree of limited cavitation, water flow velocity and pressure mutation, and low sterilization efficiency It may be too high to achieve the effect of compact device, easy automation and moderate maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

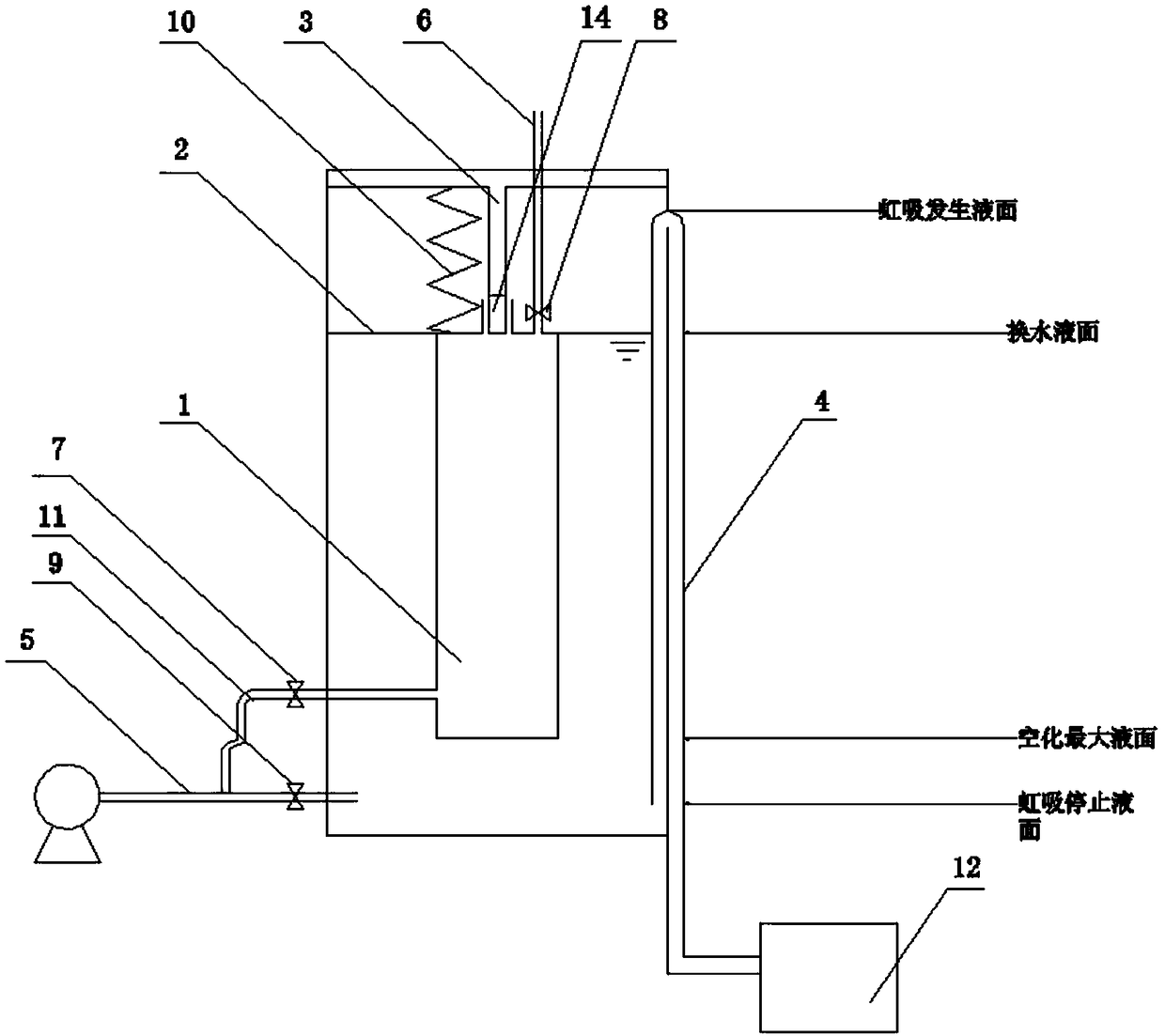

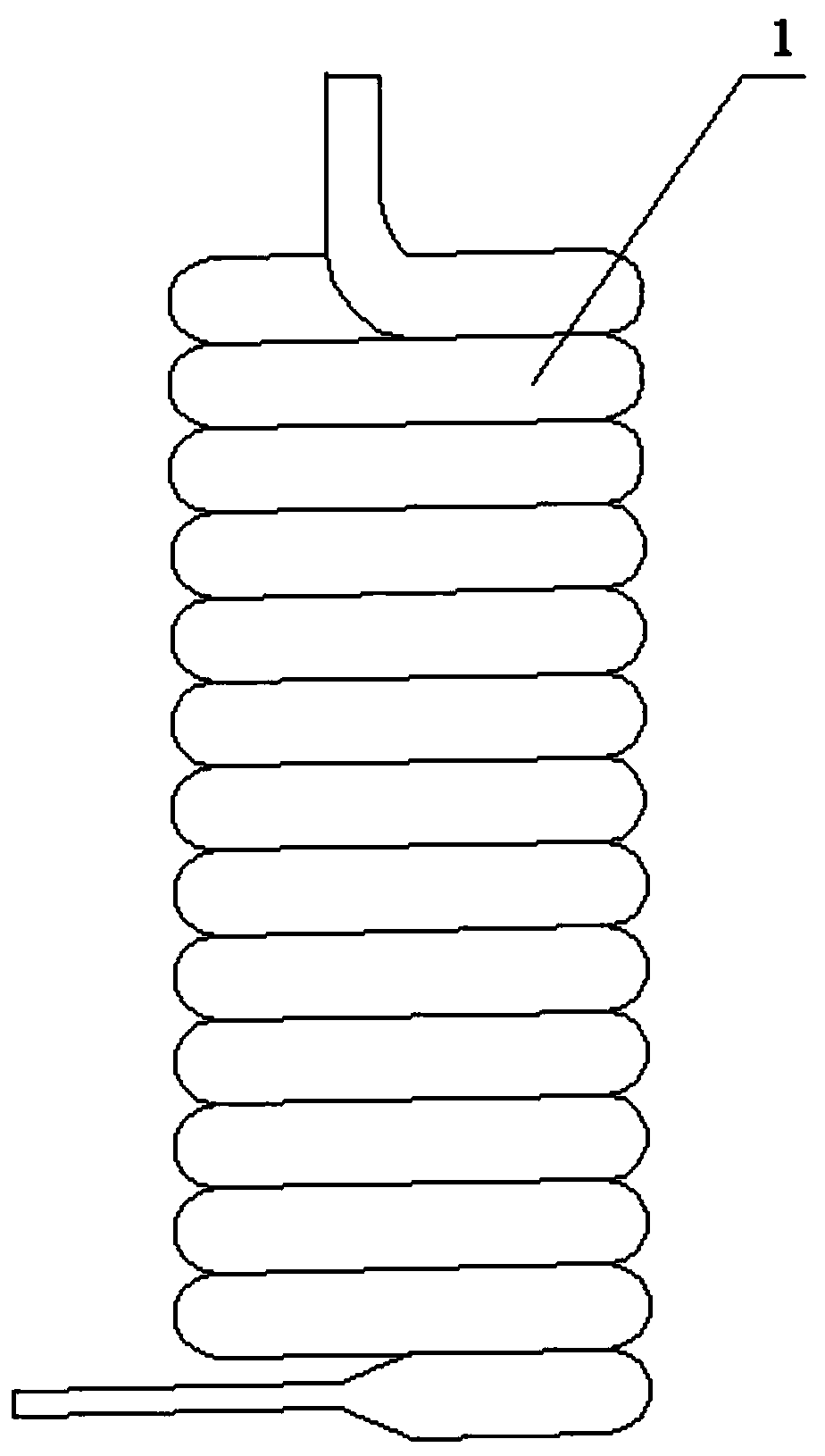

[0020] exist figure 1 In the schematic diagram of the present invention shown, the water level control chamber 2 is a cavity, and the side wall of the water level control chamber is provided with a water inlet pipe A5, and one end of the water inlet pipe A5 is placed outside the water level control chamber. The other end of A5 extends to the inside of the water level control chamber. The water inlet pipe A5 is connected to one end of the water inlet pipe B11, the other end of the water inlet pipe B11 extends to the inside of the water level control room, the part of the water inlet pipe B extending to the water level control room is a hose, and the other end of the water inlet pipe B is connected to the gravity space. The side walls of the cavitator 1 are connected and communicate with the inside of the self-gravity cavitator. The water inlet pipe A5 and the water inlet pipe B11 are respectively provided with a shunt valve 9 and a water outlet electric valve 7 . One end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com