Continuous flow partial nitrification parallel integration anaerobic ammonia oxidation denitrification phosphorous removal SBBR (Sequencing Batch Biofilm Reactor) process

An anammox and denitrification phosphorus removal technology is applied in the field of continuous flow short-range nitrification parallel integrated anammox denitrification phosphorus removal SBBR process, which can solve the problems of increased operating costs and difficulty in reaching the standard of effluent, and achieve carbon saving source, saving renovation costs, and the effect of large-scale engineering significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

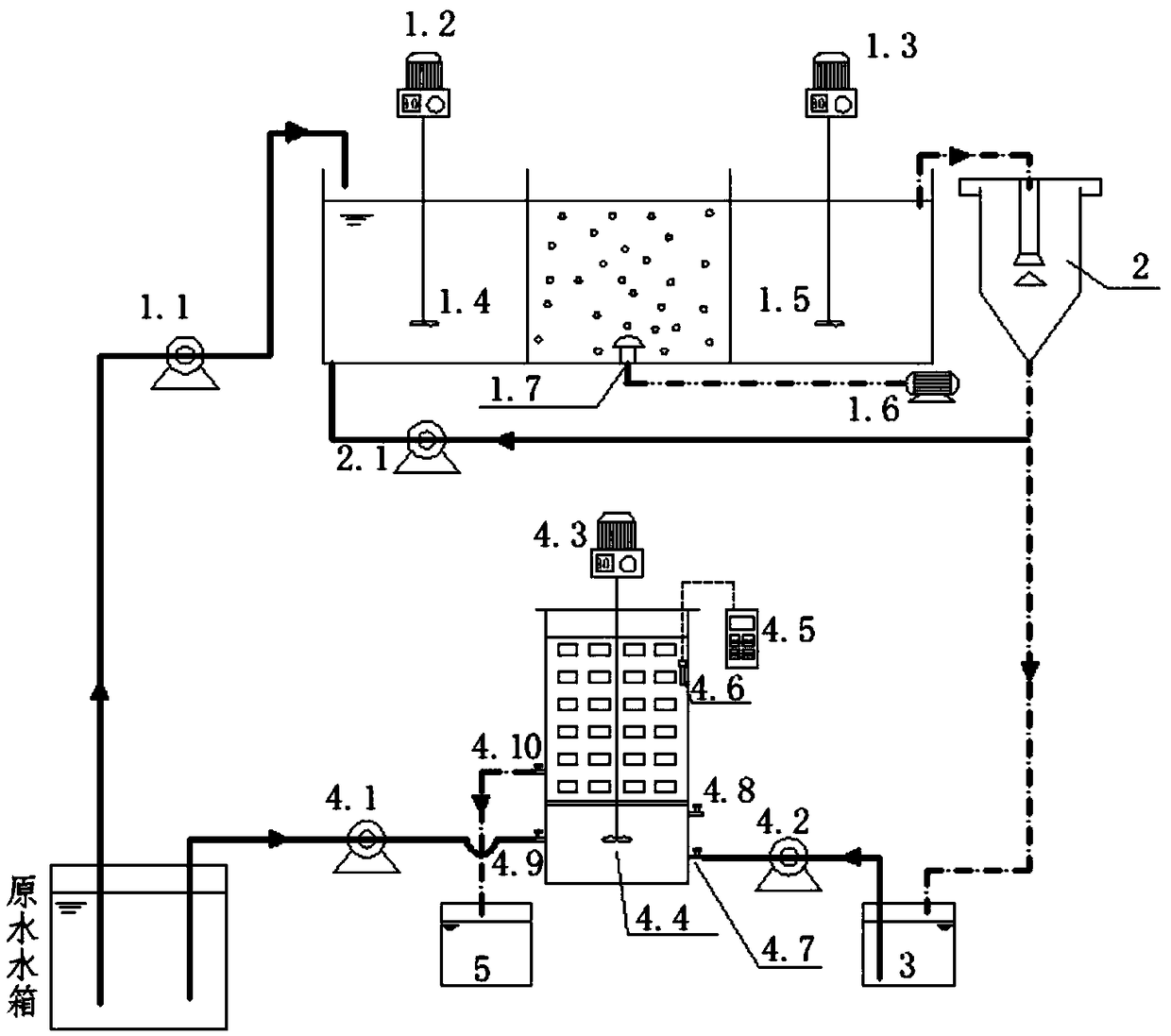

[0028] Below in conjunction with accompanying drawing, the present invention will be further described: figure 1 As shown, the continuous-flow short-path nitrification parallel integrated anaerobic ammonium oxidation denitrification phosphorus removal process for treating low C / N ratio urban sewage is characterized in that it includes: a first water inlet pump 1.1, a second water inlet pump 4.1, and a first agitator 1.2, the second agitator 1.3, the third agitator 4.3, the first agitator 1.4, the second agitator 1.5, the third agitator 4.4, aeration pump 1.6, aeration head 1.7, sludge return pump 2.1, secondary sedimentation Pool 2, intermediate water tank 3, pH / DO probe 4.6, pH / DO meter 4.5, first water inlet 4.9, second water inlet 4.7, mud discharge port 4.8, drain port 4.10, and drain bucket 5. Among them, the urban sewage raw water enters the short-path nitrification continuous flow reactor and the anaerobic ammonium oxidation denitrification phosphorus removal integrated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com