Moisture absorbing and water retaining type mining foam generator and preparation method thereof

A foam generating and water-retaining technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of poor wettability and short half-life of foam generating agents, so as to enhance the ability of moisture absorption and water retention, maintain water content, enhance mutual attraction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

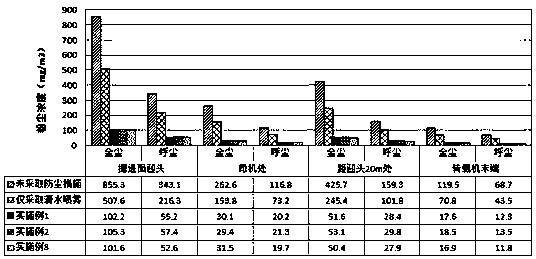

Examples

preparation example Construction

[0075] The invention provides a moisture-absorbing and water-retaining foam generating agent for mines and a preparation method thereof, wherein, according to mass percentage, it comprises the following components: 0.1%-0.2% fatty alcohol polyoxyethylene ether, 0.05%-0.1% secondary Sodium alkylsulfonate, 0.2%~0.4% octadecyltrimethylammonium chloride, 0.02%~0.03% fatty acid diethanolamide, 0.03%~0.05% amine oxide, 0.2%~0.3% lauryl alcohol Potassium ether phosphate, 0.1%~0.2% dioctyl sodium dibutyrate sulfonate, 0.1%~0.2% sodium chloride, 0.05%~0.1% sodium carboxymethyl starch, 0.01%~0.04% Sorbitan monooleate polyoxyethylene ether, the balance is water. The expansion ratio of the foam generating agent is increased to 120-230 times, and the half-life of the foam is increased to 55 minutes without external interference. Due to its high wettability, the foam is measured by a contact angle tester The contact angle of the generating agent to dust is reduced to below 2.5°, which can ...

Embodiment 1

[0085] 1g of fatty alcohol polyoxyethylene ether, 0.6g of sodium secondary alkylsulfonate, 3g of octadecyltrimethylammonium chloride, 0.2g of fatty acid diethanolamide, 0.4g of amine oxide, 2g of lauryl alcohol Potassium ether phosphate, 2 g of dioctyl sodium dibutyrate sulfonate, 1 g of sodium chloride, 0.5 g of sodium carboxymethyl starch, 0.3 g of sorbitan monooleate polyoxyethylene ether were added to 989.0 g of water, make it fully mixed, completely dissolved, and finally configured into 1000kg of foam generating agent solution. In the foam generating agent, the proportion of fatty alcohol polyoxyethylene ether is 0.1%, the proportion of sodium secondary alkylsulfonate is 0.06%, and the proportion of octadecyltrimethylammonium chloride is 0.3%. The proportion of fatty acid diethanolamide is 0.02%, the proportion of amine oxide is 0.04%, the proportion of potassium lauryl ether phosphate is 0.2%, the proportion of dioctyl sulfonate dibutyrate is 0.2%, and the proportion of...

Embodiment 2

[0087] 2g of fatty alcohol polyoxyethylene ether, 0.5g of sodium secondary alkylsulfonate, 4g of octadecyltrimethylammonium chloride, 0.3g of fatty acid diethanolamide, 0.3g of amine oxide, 3g of lauryl Potassium alcohol ether phosphate, 1g of dioctyl sodium dibutyrate sulfonate, 2g of sodium chloride, 1g of sodium carboxymethyl starch, 0.4g of sorbitan monooleate polyoxyethylene ether added to 985.5g In the water, make it fully mixed, completely dissolved, and finally configured into a 1000kg foam generating agent solution. In the foam generating agent, the proportion of fatty alcohol polyoxyethylene ether is 0.2%, the proportion of sodium secondary alkylsulfonate is 0.05%, and the proportion of octadecyltrimethylammonium chloride is 0.4%. The proportion of fatty acid diethanolamide is 0.03%, the proportion of amine oxide is 0.03%, the proportion of potassium lauryl ether phosphate is 0.3%, the proportion of dioctyl sodium sulfonate dibutyrate is 0.1%, and the proportion of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com