A-level fireproof inorganic heat-insulating decoration integral board and manufacturing method thereof

An inorganic thermal insulation and manufacturing method technology, which is applied in the direction of manufacturing tools, ceramic molding machines, building structures, etc., can solve the problem of incompatibility of thermal insulation performance and fireproof performance of insulation boards, failure to achieve ultra-low thermal conductivity, failure to meet market demand, etc. problem, to achieve good thermal insulation effect, save material consumption, and save material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

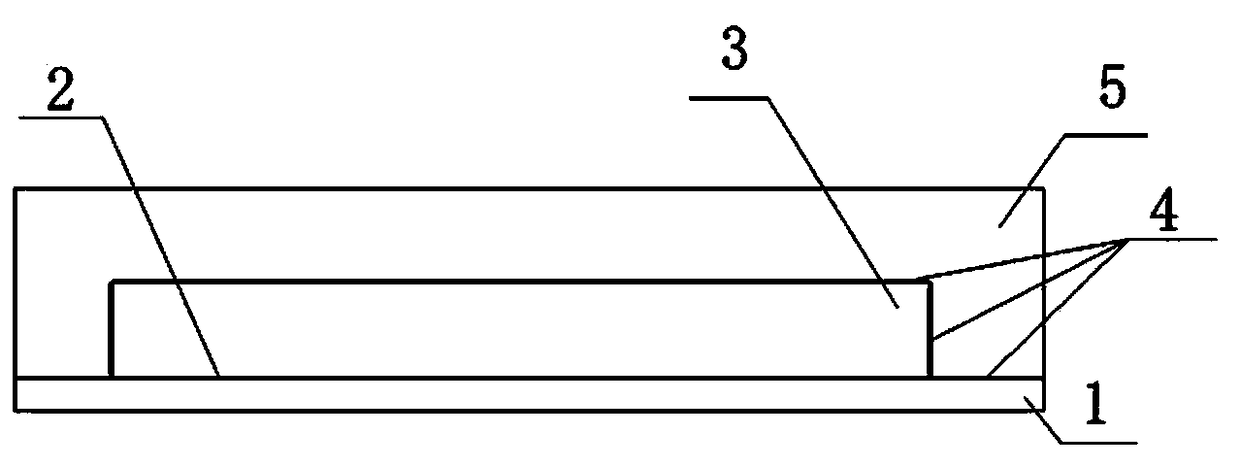

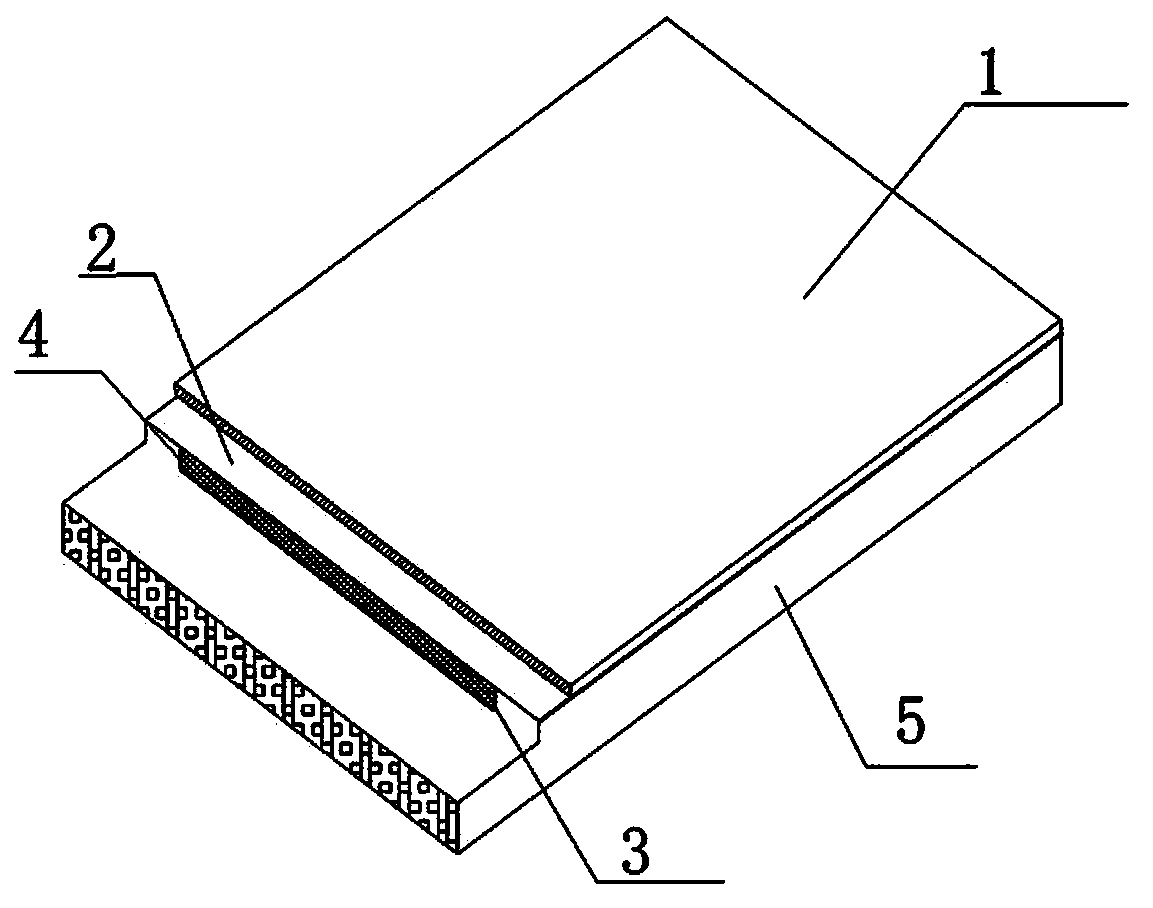

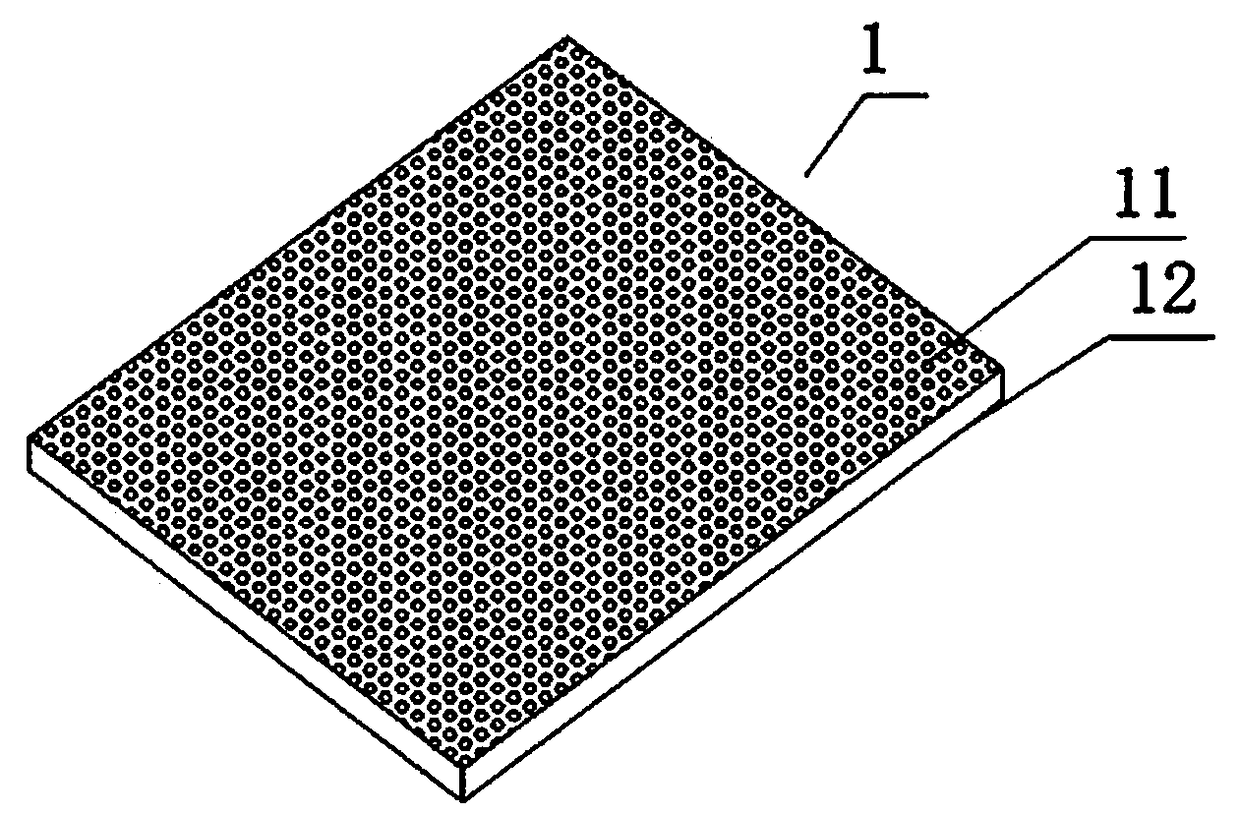

[0035] like figure 1 , figure 2 and image 3 As shown, the present invention discloses an A-level inorganic thermal insulation and decoration integrated board, which is a laminated structure, including an inorganic decorative panel layer 1, an adhesive layer 2, a core material layer 3, an interface agent layer 4 and a thermal insulation slurry cladding layer 5, wherein the inorganic decorative panel layer 1 includes a decorative surface 11 and a bonding surface 12, the core material layer 3 is bonded to the bonding surface 12 through the adhesive layer 2, and the thermal insulation slurry cladding layer 5 is completely covered on the surface through the interface agent layer 4 On the core material layer 3, the shape and size of the thermal insulation slurry cladding layer 5 are consistent with the inorganic decorative panel layer, the size of the core material layer 3 is smaller than the size of the inorganic decorative panel layer, and the core material layer 3 is a nano-sc...

Embodiment 2

[0048] This example refers to the structure and manufacturing process of the A-level inorganic fireproof, thermal insulation and decorative integrated board in Example 1. The difference from the scheme in Example 1 is that, as Figure 4 , Figure 5 As shown, a texture 13 is provided on the joint surface 12, and a right-angle inflection point 131 is also provided on the texture 13, and notch breakpoints 132 are also provided on both sides of the right-angle inflection point 131. The effect of adopting this structure is that firstly Arranging lines 13 on the joint surface 12 can increase the joint effect of the joint surface 12. Further, the right-angle inflection point 131 provided on the line 13 can make the inorganic decorative panel layer 1 be able to withstand greater The horizontal force, in other words, is stronger and firmer.

[0049] After the right-angle inflection point 131 is set, the firmness in the horizontal direction is improved, but at the inflection point of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com