Primary air pressure control method for coal mill unit and control system

A pressure control and control system technology, applied in the field of electric power, can solve problems such as energy waste, failure to consider the operation of the coal mill, and reduce the economy of the unit, so as to achieve the goals of reducing power consumption, accurate and objective calculation, and reducing energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

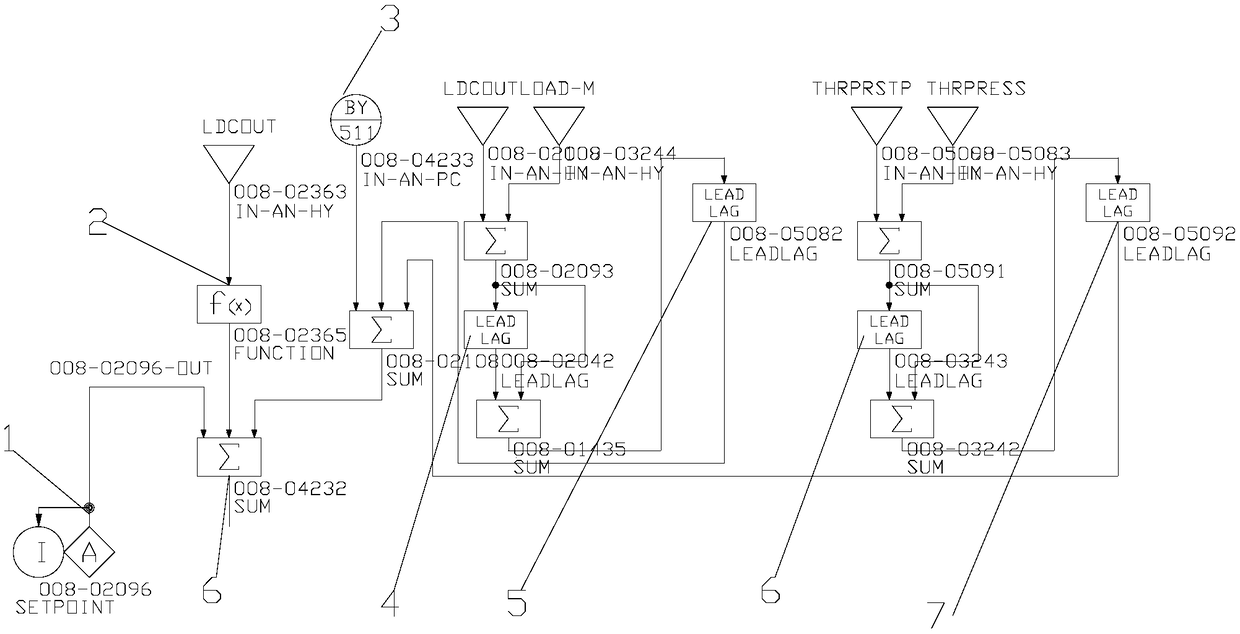

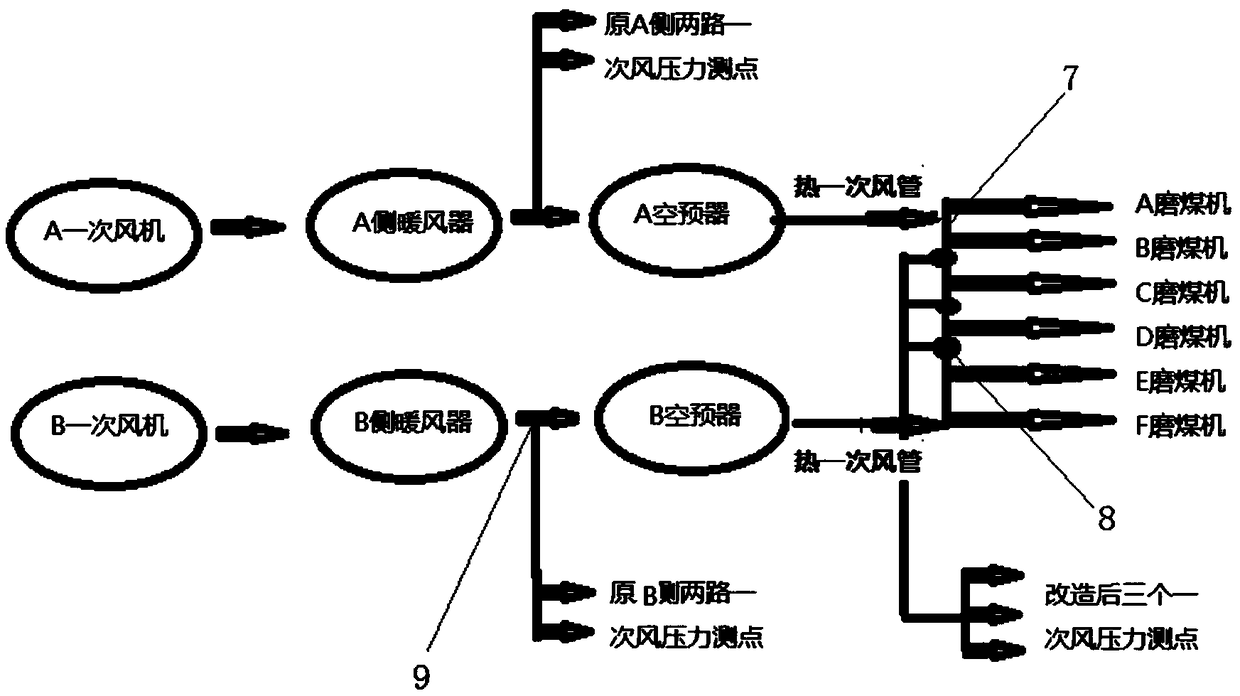

[0051] like Figure 1 to Figure 2 As shown, this embodiment discloses a method for controlling primary air pressure of a coal mill unit. One unit of a thermal power plant is generally equipped with two primary fans, and multiple coal mills blow the pulverized coal inside to the boiler for combustion through the primary wind pressure provided by the primary fans to realize energy conversion. In order to better control the pulverized coal entering the furnace, on the one hand, it depends on the output of the coal mill, and on the other hand, it depends on the primary air pressure setting value of the primary air of the coal wind volume). The primary air pressure setting value of the coal mill unit is obtained by the control system through calculation of the primary air pressure setting value variable.

[0052] like figure 1 As shown, the variable of the primary air pressure setting value of the present invention includes: the function value of the load command after being cal...

Embodiment 2

[0074] This embodiment discloses a control system that applies the primary air pressure control method of the coal mill unit as described in Embodiment 1. The set value of the primary air pressure of the coal mill unit is obtained by calculating the variable of the set value of the primary air pressure. The variable of the primary air pressure setting value includes: the function value of the load command after the function calculation, the total air volume required by the coal mill, the bias set by the operator, the load command and the load deviation value of the unit, and the main steam pressure setting value The deviation from the actual main steam pressure of the unit.

[0075] like figure 1 As shown, the variable of the primary air pressure setting value of the present invention includes: the function value of the load command after being calculated by the function 2 of the load command of the unit, the total air volume 3 required by the coal mill, the bias 1 set by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com