Skidded moving type carbon dioxide oil displacing production gas recovery system

A technology of carbon dioxide and recovery system, which is applied in the field of oil well output gas recovery, can solve the problems of waste of environmental protection resources, etc., achieve the effect of improving product quality, shortening the process, and avoiding the effect of low cooling temperature zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention is further described and understood by non-limiting examples below.

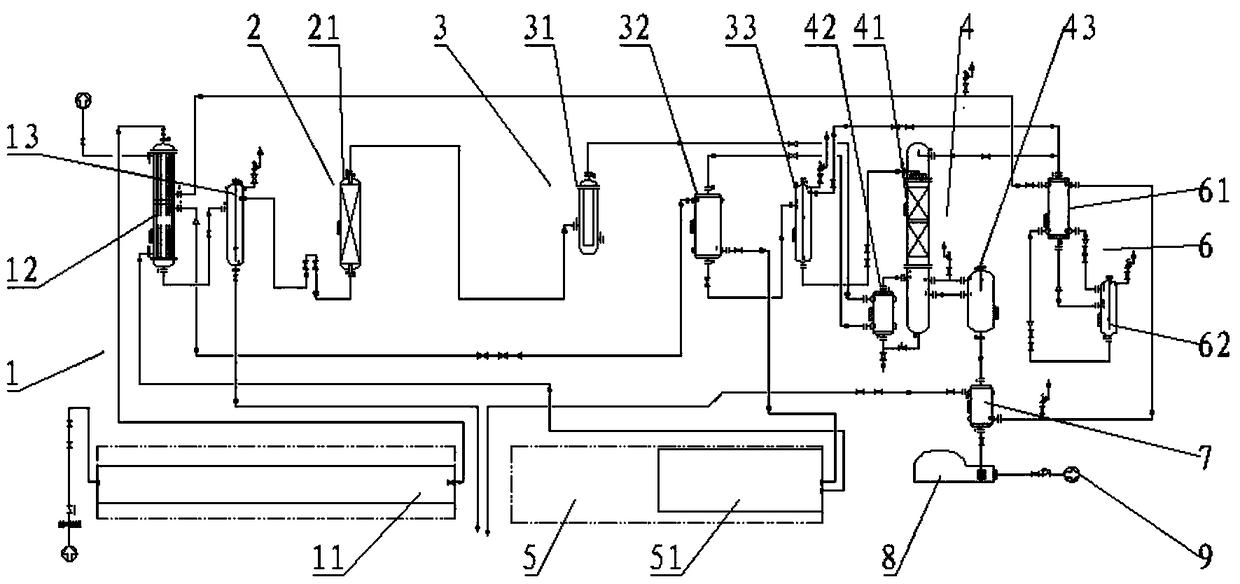

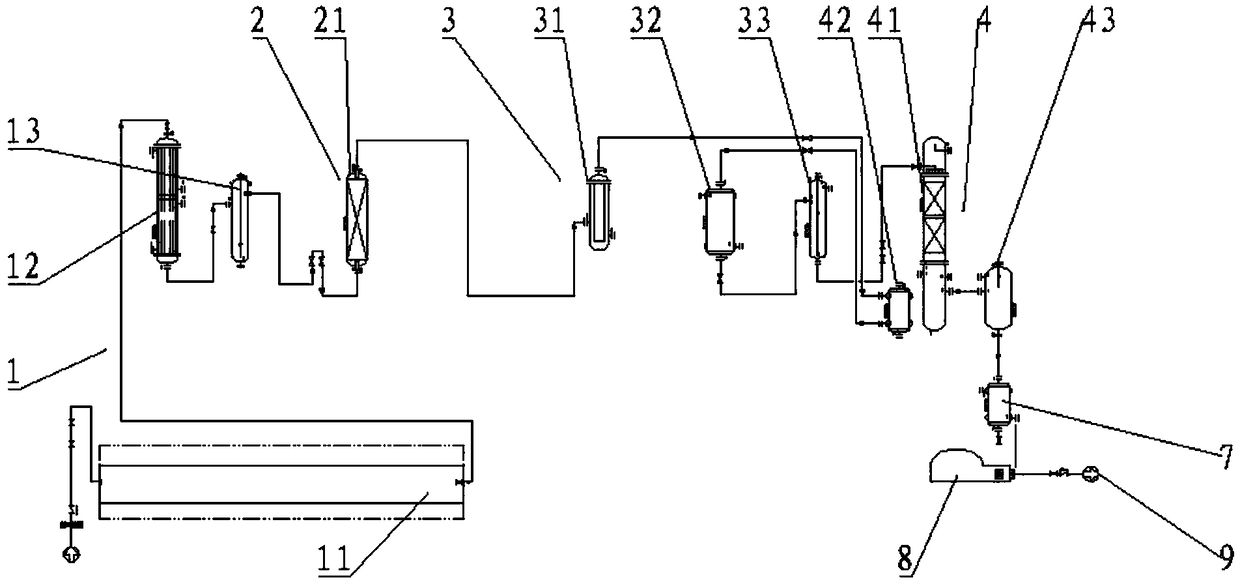

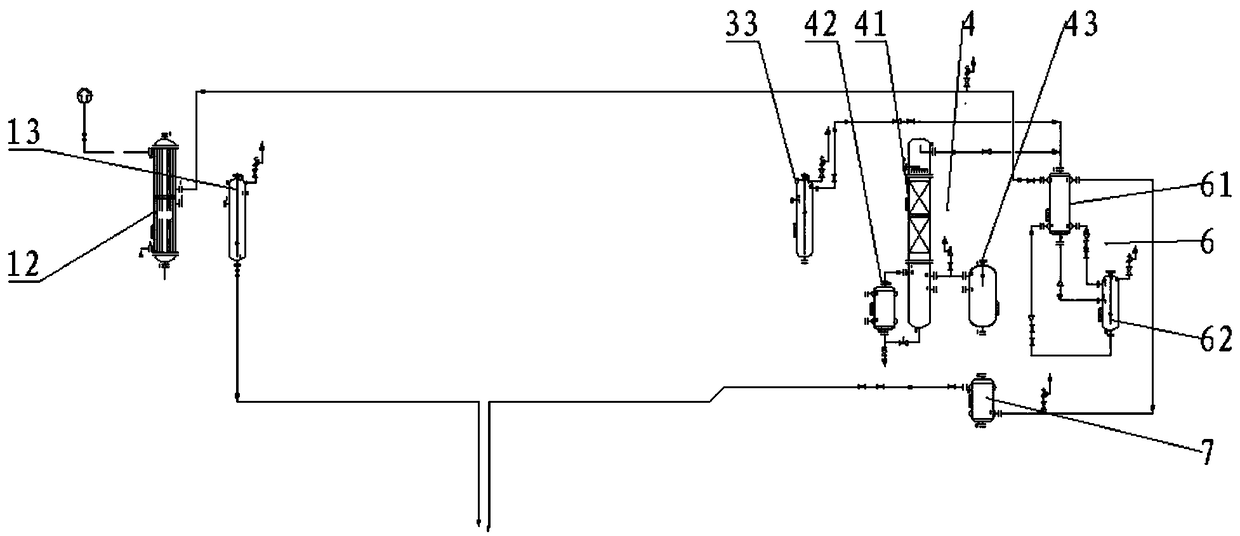

[0037] like figure 1 As shown, the present invention is a skid-mounted mobile carbon dioxide flooding output gas recovery system, which is mainly composed of a carbon dioxide compression unit 1, a drying unit 2, a carbon dioxide condensation liquefaction unit 3, a stripping unit 4, a refrigeration unit 5, and tail gas liquefaction and separation The unit 6 is composed of a carbon dioxide compression unit 1 comprising a carbon dioxide compressor 11, a feed gas cooler 12, a gas-liquid separator 13, a drying unit 2 comprising a drying tower 21, and a carbon dioxide condensation liquefaction unit 3 comprising a carbon dioxide filter 31, a carbon dioxide condenser 32 and The carbon dioxide intermediate tank 33, the stripping unit 4 includes a stripping tower 41, a stripping tower reboiler 42, and a stripping tower intermediate tank 43, the refrigeration unit 5 includes a Freon refrige...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com