Optical fiber grating composite insulator for ice coating state measurement and manufacturing method thereof

A technology of composite insulators and optical fiber gratings, applied in the direction of insulators, electrical components, circuits, etc., can solve the problems of inaccurate monitoring results, low data transmission and communication technology, and poor power extraction effect, and achieve strong anti-interference ability and improved survival The effect of high efficiency and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

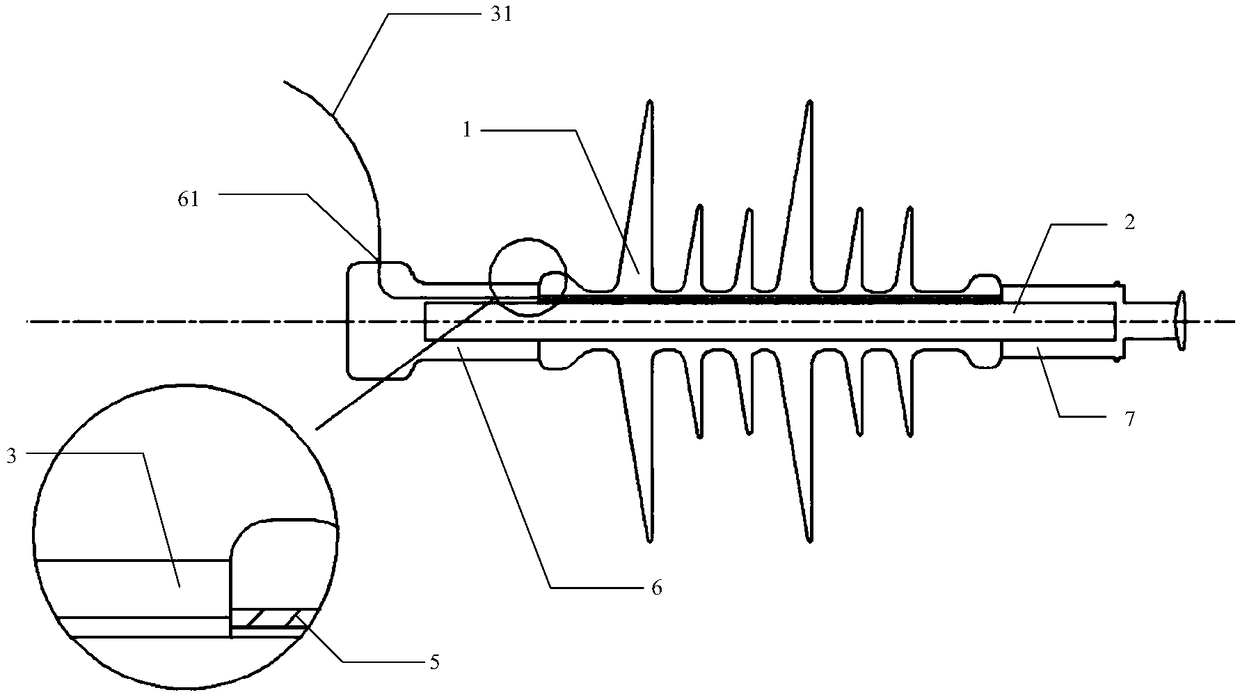

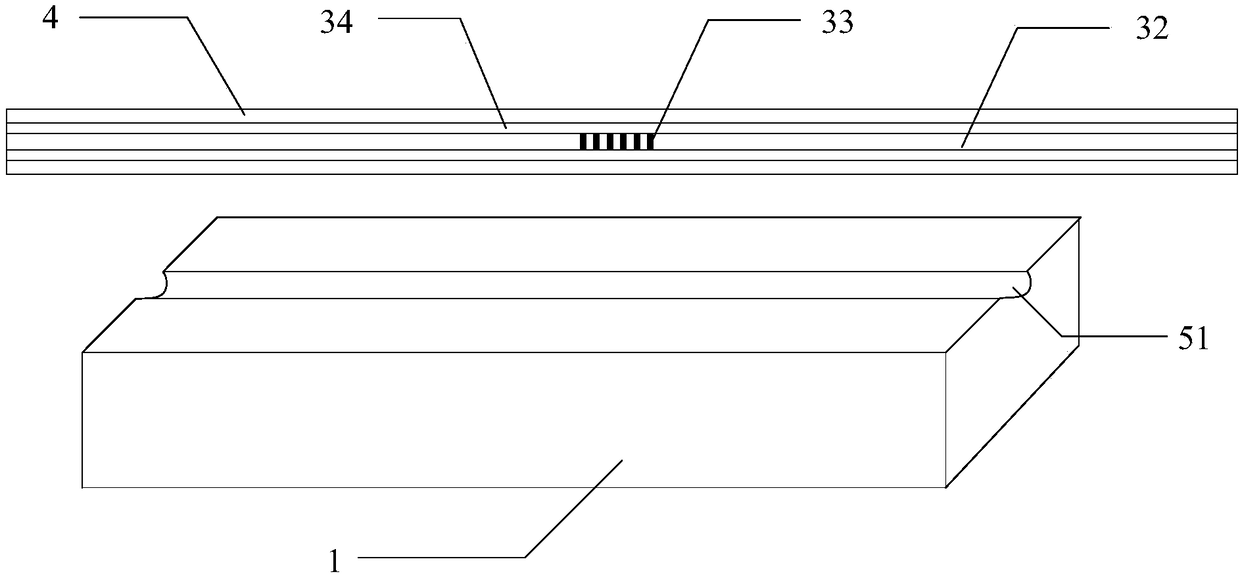

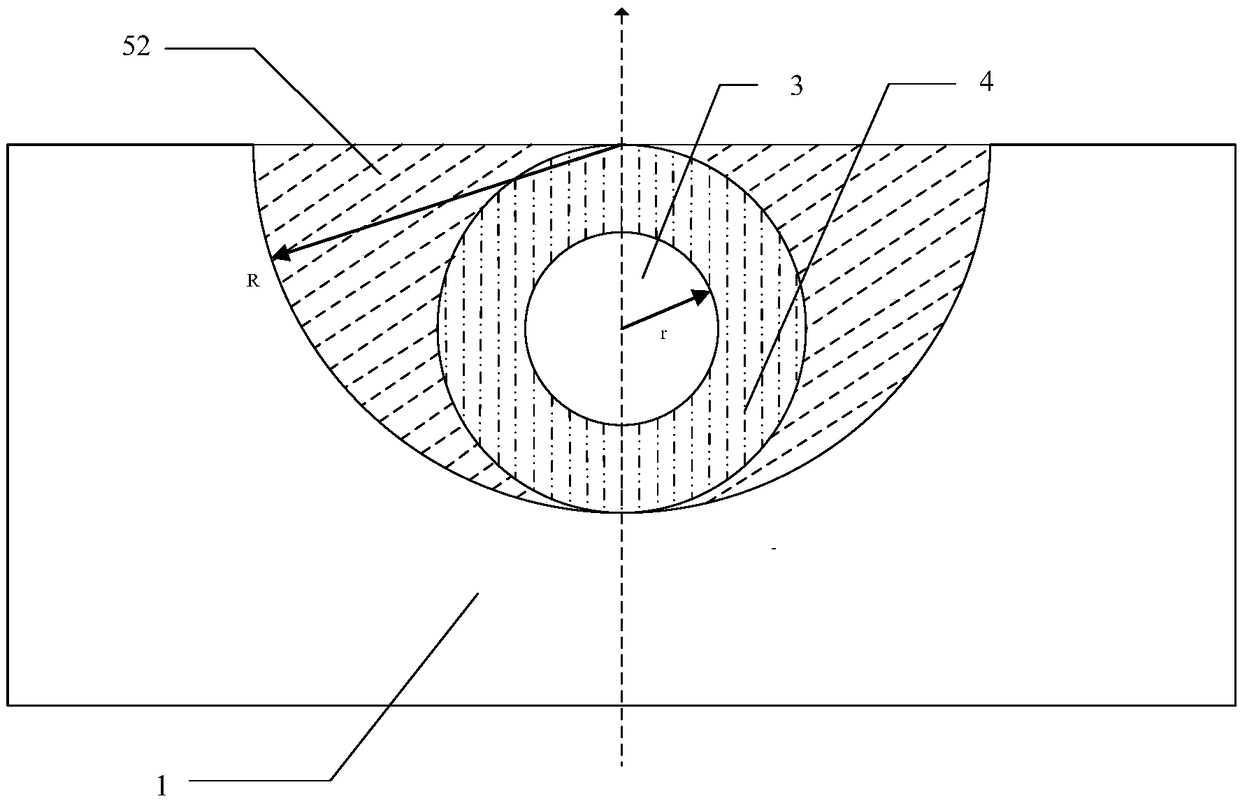

[0030] This embodiment provides a fiber grating composite insulator for ice-covered state measurement, the structure diagram is as follows figure 1 As shown, the silicon rubber sheath (1) of the fiber grating composite insulator is implanted with an optical fiber (3) parallel to the core rod (2), and the optical fiber (3) includes a core (32), a pigtail ( 31) and cladding (34), the optical fiber (3) is provided with a grating (33) and socketed protective sleeve (4), such as figure 2 with image 3 As shown, a groove (51) is engraved on the assembly surface of the silicone rubber sheath (1) facing the core rod (2), and the optical fiber (3) covered with the protective sheath (4) is put into the groove (51), and used The liquid material fills the groove (51) to fix the optical fiber (3), such as image 3 shown in the groove (5) filled with RTV glue containing the RTV glue layer (52); the two ends of the mandrel are respectively crimped with low-voltage end fittings (6) and hig...

Embodiment 2

[0033] This embodiment provides a method for preparing a fiber grating composite insulator for ice-covered state measurement, the method comprising the following steps:

[0034] Step 1: Soak the glass fiber in epoxy resin glue, use the tractor to introduce the soaked glass fiber into the mold to obtain the mandrel (2), then put the mandrel into the extruder, and the surface of the mandrel has a layer thickness A silicone rubber sheath (1) of about 4mm;

[0035] Step 2: Cut a semicircular groove (51) with a diameter radius of about 3mm on the surface of the silicone rubber sheath, then put the optical fiber into the groove (51), and fill the groove (51) with RTV glue, filling During the process, try to ensure that the optical fiber (3) is closely attached to the upper surface of the RTV adhesive layer (52), so as to reduce the influence of the RTV adhesive layer (52) on the stress transmission of the grating;

[0036] Step 3: Connect low-voltage end fittings (6) and high-volta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com