Driving power supply of semiconductor laser

A technology for driving power supply and laser, which is applied to semiconductor lasers, lasers, laser parts, etc., can solve the problems of lack of real-time performance of driving power supply, differences in the characteristics of components and components, large output current error, etc., and achieve good real-time performance and stability. stability, reducing output error and output stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

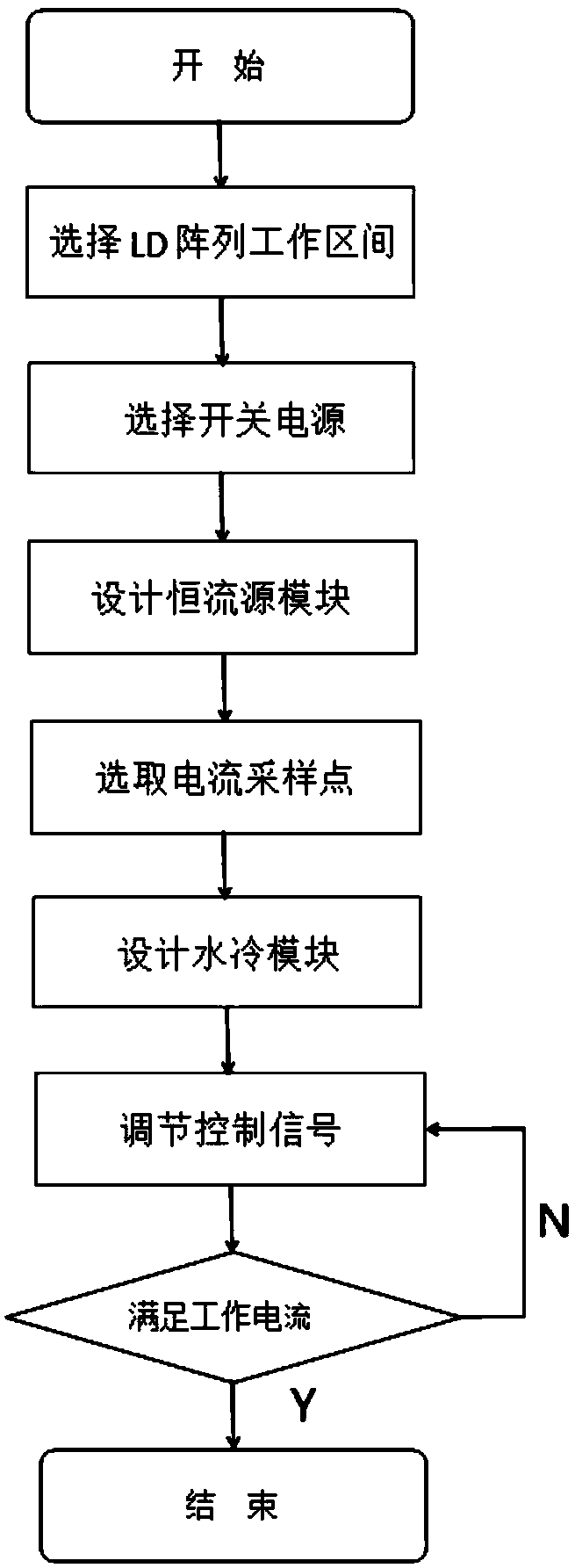

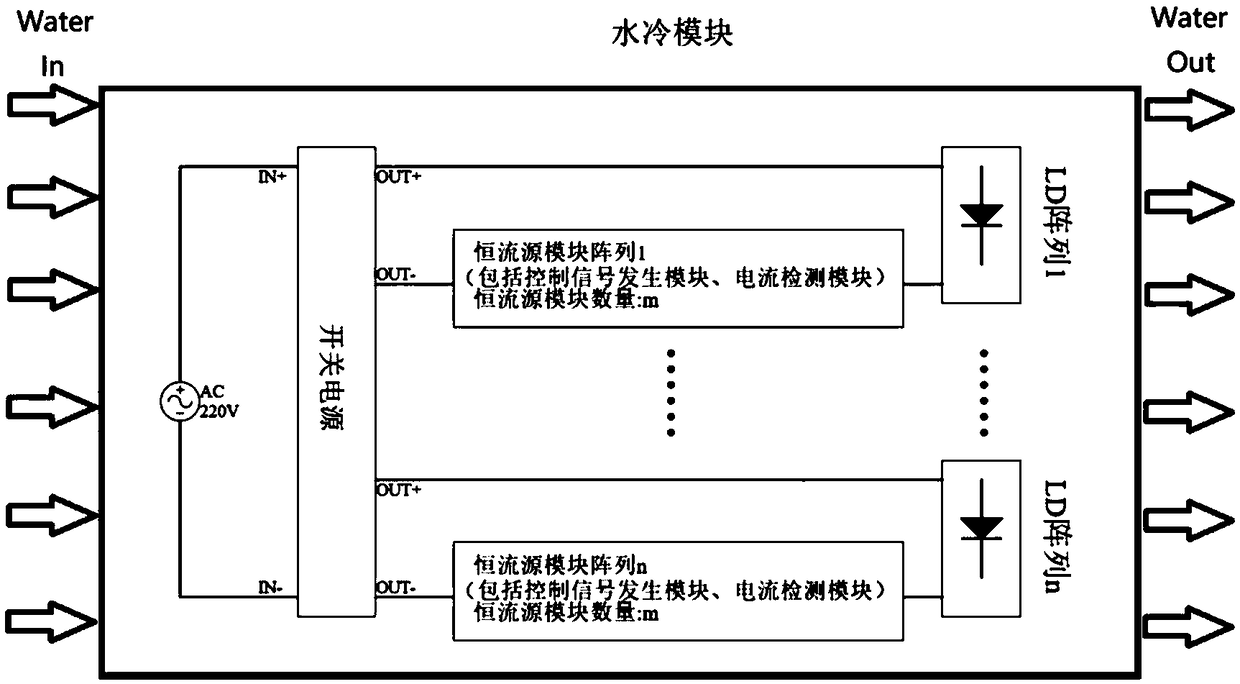

Method used

Image

Examples

Embodiment

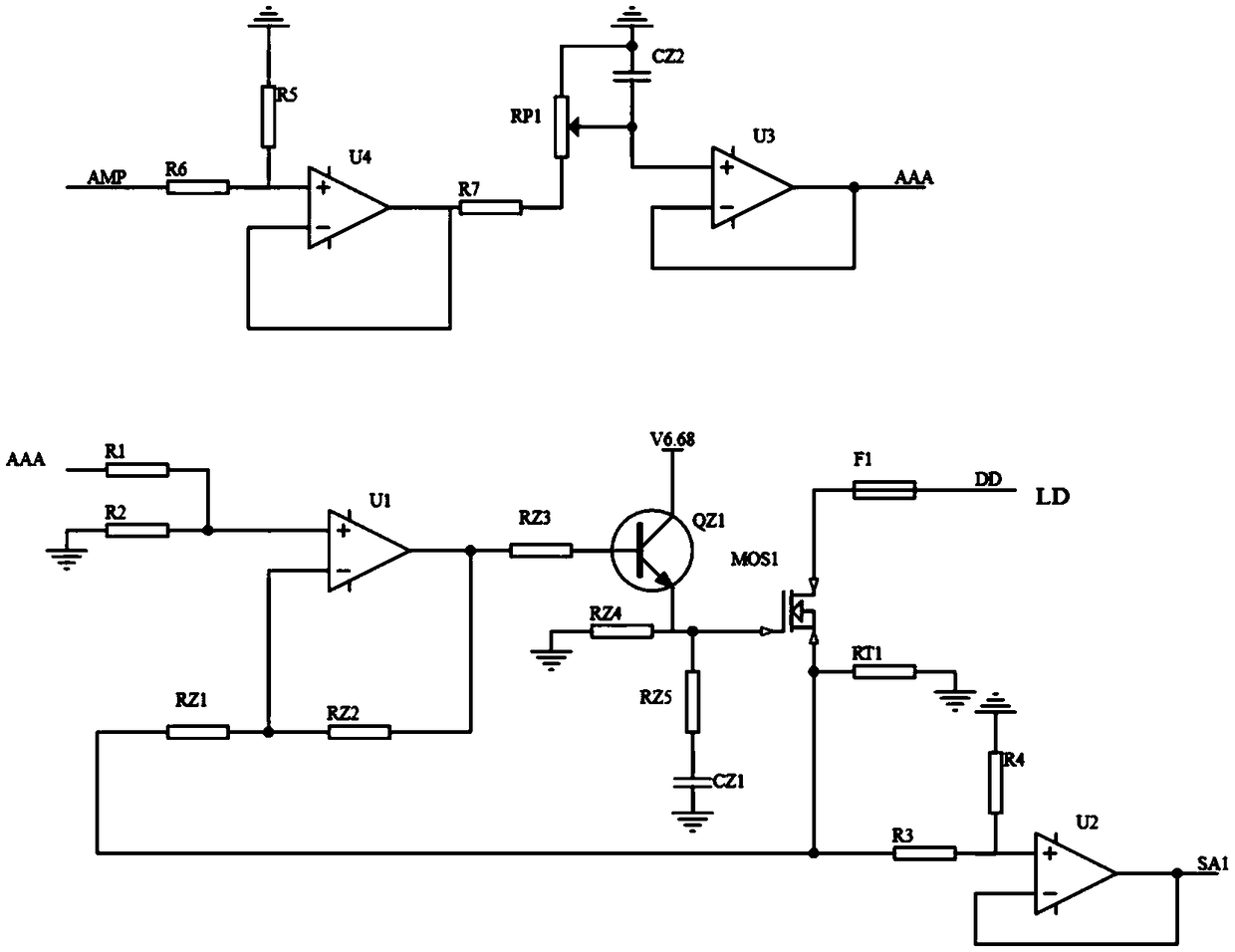

[0036] In the embodiment of the present invention, a pump source of a certain brand, namely LD, is used. Its working rated voltage is 15V, and its rated current is 13A. It requires 3 sets of pumps to be used in series. Select a switching power supply with a rated output voltage of 48V and a maximum output current of 15A according to the load requirements. The constant current source module circuit built is as follows: Figure 4 As shown, the constant current source module includes a first resistor R1, a second resistor R2, a third resistor RZ1, a fourth resistor RZ2, a fifth resistor RZ3, a sixth resistor RZ4, a seventh resistor RZ5, an eighth resistor RT1, a ninth resistor Resistor R3, tenth resistor R4, eleventh resistor R5, twelfth resistor R6, thirteenth resistor R7, first sliding rheostat RP1, first capacitor CZ1, second capacitor CZ2, first operational amplifier LM258 chip U1, The second operational amplifier LM258 chip U2, the first NPN transistor QZ1, the first N-chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com