Preparation method of euli freeze-dried powder and euli health product

A technology of freeze-dried powder and health products, which is applied in food freezing, food ingredients, food preservation, etc., can solve the problems of loss of amino acid and active calcium components, failure to maintain the nutritional value of Prune fruit, loss of nutritional value of Plum fruit, etc. Achieve excellent eating experience, retain nutritional value, and increase shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

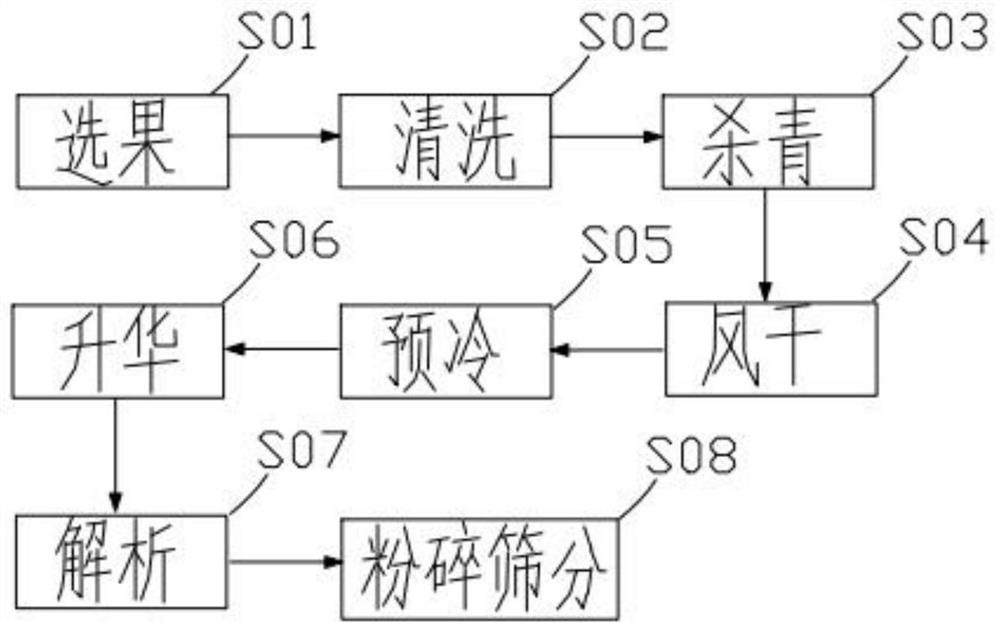

[0037] In the present embodiment, the preparation method of the freeze-dried powder of Ou Li includes the following steps:

[0038] S01: Fruit selection: Eliminate immature, damaged or rotten Prunus fruits.

[0039] S02: Cleaning: Clean the surface of the fruit, remove the core, slice into 0.1cm-2cm slices, and set aside. As a preference, during the cleaning process, a salt solution with a mass fraction of 2% to 5% can be used for cleaning and soaking for 5 to 10 minutes. The fresh fruit is fuller, and at the same time, the taste of the prunes is improved, making it more flavorful.

[0040] S03: Greening: after the step of "cleaning", the plums are put in water at 100°C for 5 minutes to 10 minutes, and the purpose of curing is to make the fruit of the plums taste sweet and not astringent.

[0041] S04: Air-drying: After the step of "killing green", place the prunes in the air at 5°C-20°C for 2h-3h. The purpose of air-drying is to remove the water attached to the surface of t...

Embodiment 1

[0064] Embodiment 1: the preparation of Ou Li freeze-dried powder

[0065] Fruit selection: Remove immature, damaged or rotten Oli fruit.

[0066] Cleaning: Clean the surface of the fruit, remove the core, slice into 0.1cm-2cm slices, and set aside.

[0067] Fixing: after the step of "cleaning", the plums are placed in water at 100°C for 5 minutes.

[0068] Air-drying: after the step of "killing the green", place the prunes at 5°C to air-dry naturally for 2 hours.

[0069] Pre-cooling: After the step of "air-drying", the Oli is pre-frozen to -60°C in the freezer. The pre-cooling process is as follows:

[0070] (1) Cool from the initial pre-cooling temperature to -4°C, the temperature drop rate is 15°C / h, the temperature drops to -4°C, and maintain for 1h;

[0071] (2) 0 is cooled from -4°C to -40°C, the temperature drop rate is 10°C / h, when the temperature drops to -20°C, -30°C, and -40°C, maintain it for 1h respectively;

[0072] (3) Cool from -40°C to -60°C, the temperat...

Embodiment 2

[0081] Embodiment 2: the preparation of Ou Li freeze-dried powder

[0082] Fruit selection: Remove immature, damaged or rotten Oli fruit.

[0083] Cleaning: Clean the surface of the fruit, remove the core, slice into 0.1cm-2cm slices, and set aside.

[0084] Fixing: after the step of "cleaning", the plums are placed in water at 100°C for 10 minutes.

[0085] Air-drying: after the step of "killing the green", place the prunes at 5°C to air-dry naturally for 3 hours.

[0086] Pre-cooling: After the step of "air-drying", the Oli is pre-frozen to -80°C in the freezer. The pre-cooling process is as follows:

[0087] (1) Cool from the initial pre-cooling temperature to -4°C, the temperature drop rate is 20°C / h, the temperature drops to -4°C, and maintain for 1h;

[0088] (2) 0 is cooled from -4°C to -40°C, the temperature drop rate is 15°C / h, when the temperature drops to -20°C, -30°C, and -40°C, maintain it for 1h respectively;

[0089] (3) Cool from -40°C to -60°C, the temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com