Nanometer composite material and preparation method and application thereof

A nanocomposite material and nanobubble technology, applied in the field of materials, can solve problems such as limited tissue penetration depth, damage to normal cells, and application limitations, and achieve the effect of increasing the concentration of chemotherapy drugs and improving the ablation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0186] According to one embodiment of the present application, a nanocomposite material is provided, including nanobubbles and outer layer components thereof;

[0187] The inner core of the nanobubble is gas;

[0188] The outer layer component is selected from at least one of surface modifiers, chemotherapy drugs, MRI contrast agents, and tumor-specific targeting molecules.

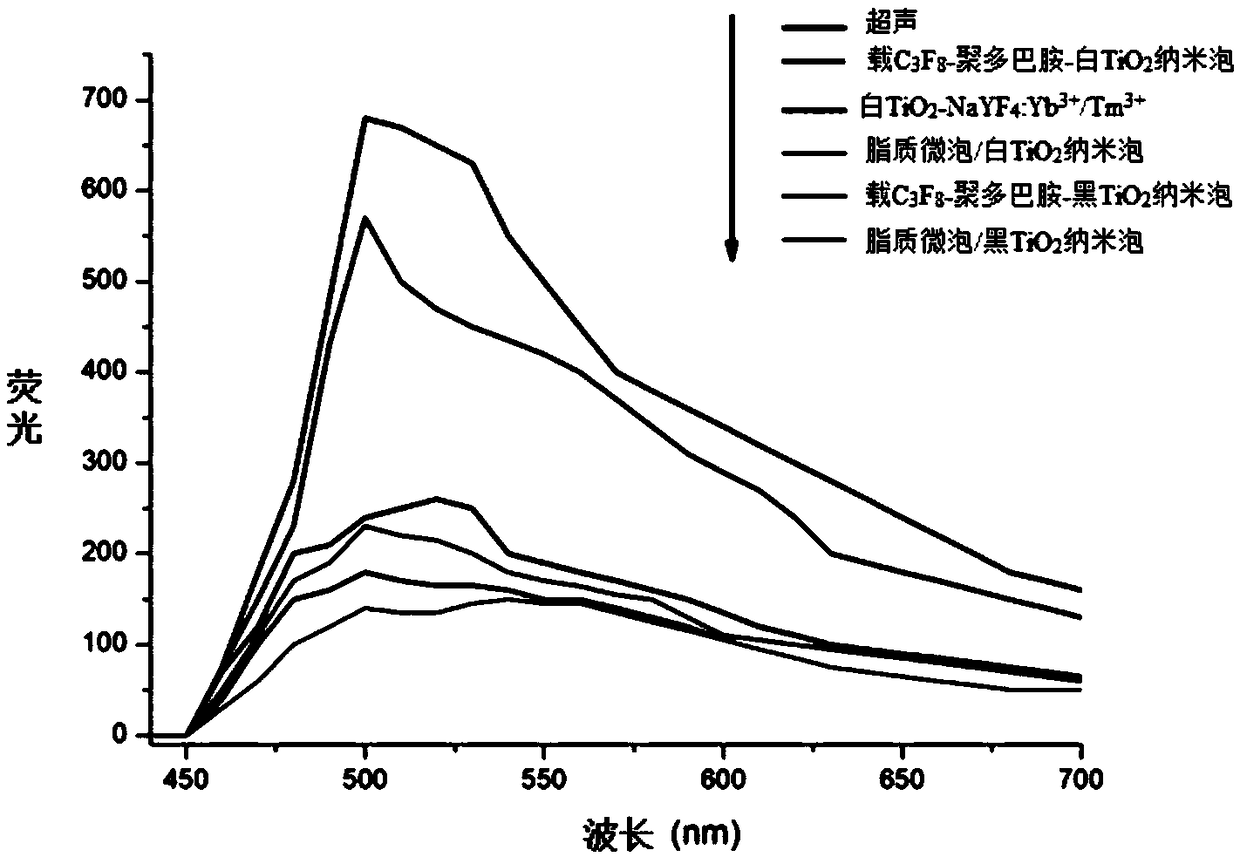

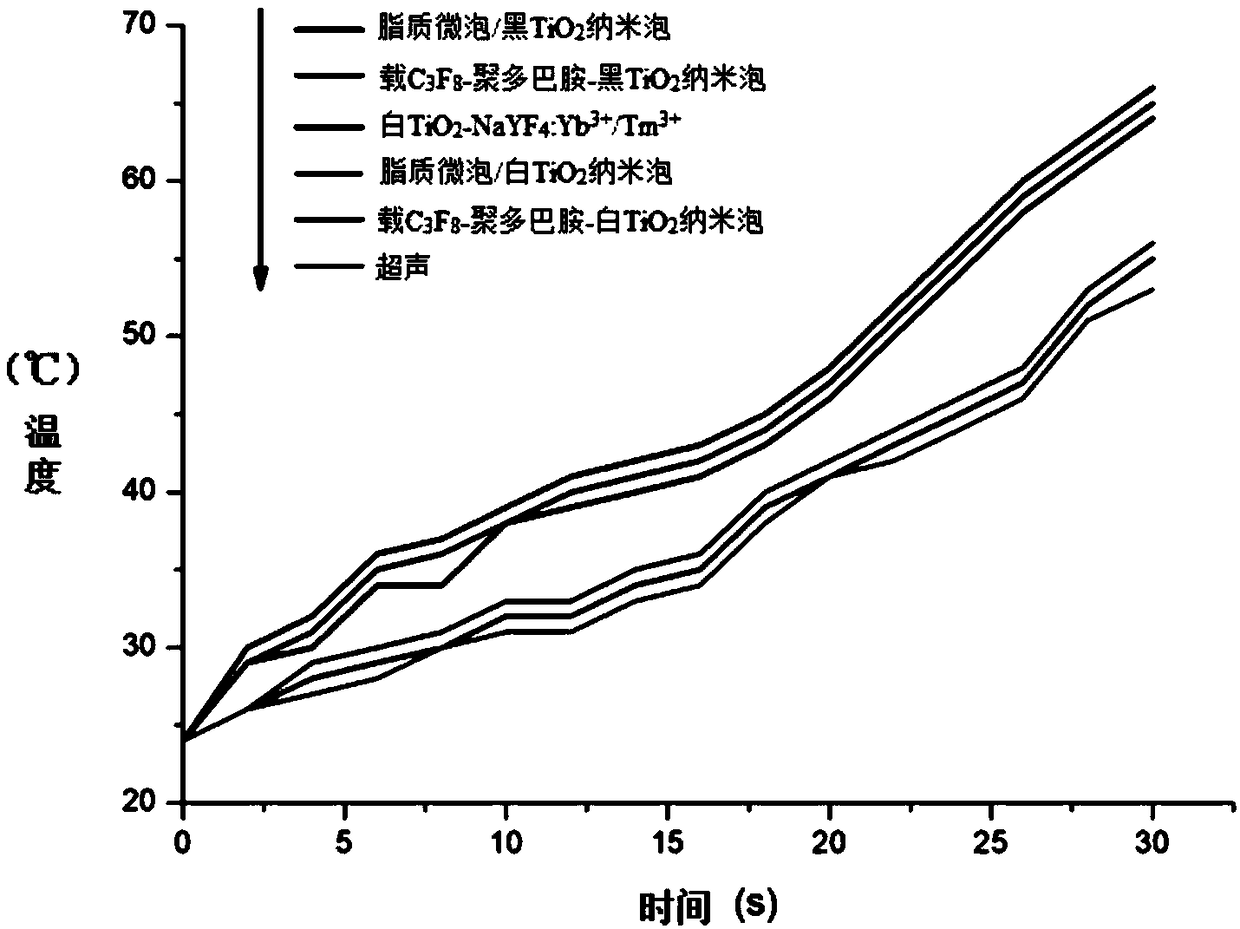

[0189] Optionally, the nanobubbles are selected from at least one of white titanium oxide nanobubbles and black titanium oxide nanobubbles.

[0190] According to one embodiment of the present application, the nanobubbles are selected from at least one of upconversion / nanobubbles in which nanobubbles are combined with upconversion substances, lipid microbubbles / nanobubbles in which nanobubbles are covalently bound to lipid microbubbles .

Embodiment 1

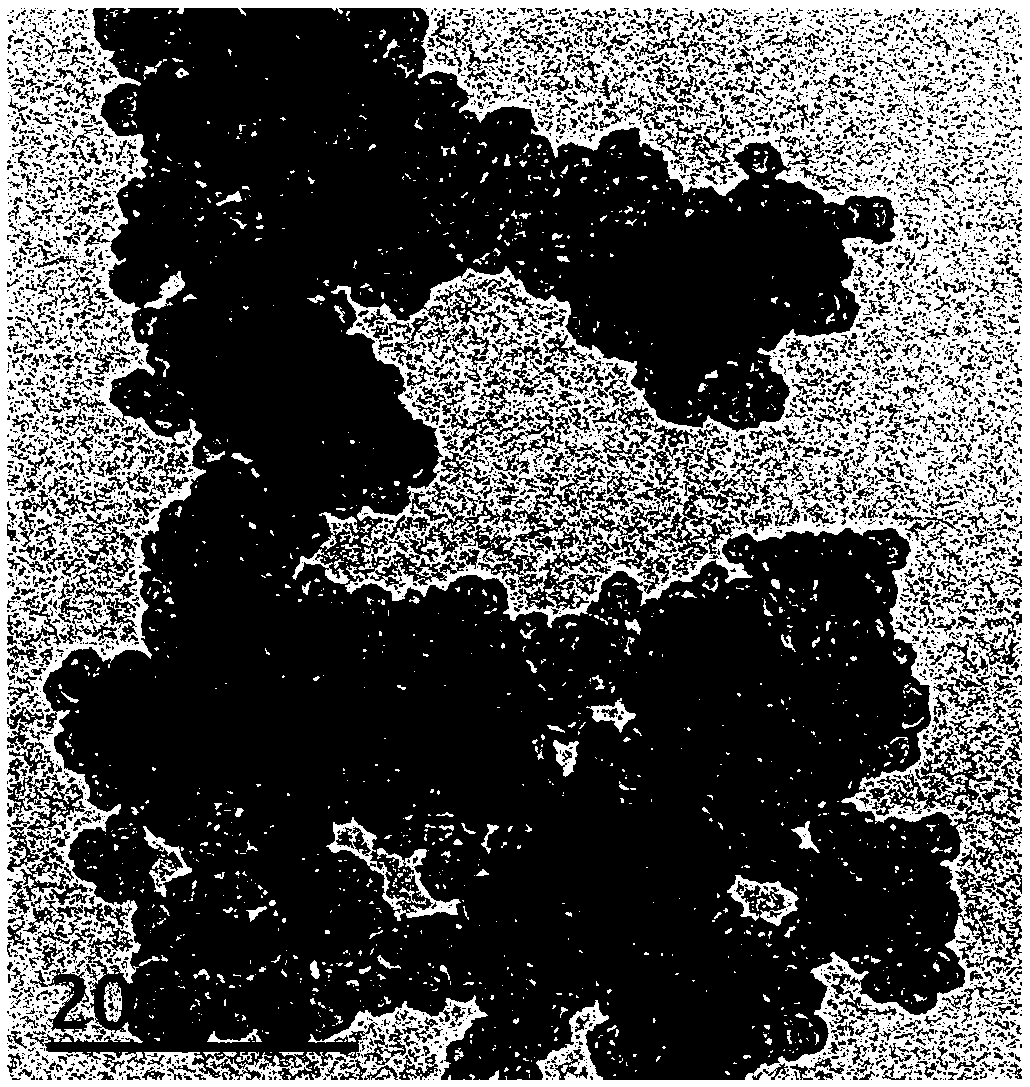

[0191] Embodiment 1: carry C 3 f 8 - Polydopamine - White TiO 2 Preparation of nanobubbles

[0192] Take 16.2 g of glucose and disperse in 180 ml of deionized water, stir, and ultrasonically disperse for 10 minutes. Place in a polytetrafluoroethylene reactor, preheat to 160°C, heat for 5 hours, centrifuge at 12,000 rpm for 15 minutes for 3 times, remove the supernatant, and precipitate into carbon spheres. Disperse in 150ml of absolute alcohol, add dropwise 0.3ml of glacial acetic acid, 5.6ml of tetrabutyl titanate (TBOT), and 1.13ml of ammonia water in sequence, in a water bath at 40°C, and stir magnetically at 800rpm for 24h. Then centrifuge at 12,000 rpm for 15 minutes for 3 times, remove the supernatant, and dry the obtained powder at 100°C for 4 hours. The obtained samples were calcined in a tube furnace at 500°C in air for 2 hours to remove the carbon nuclei and obtain a hollow TiO 2 nanobubbles, the C 3 f 8 Gas filled in hollow TiO 2 Nanobubbles were dispersed i...

Embodiment 2

[0193] Example 2: Lipid microbubbles / white TiO 2 Preparation of nanobubble covalently bonded composites

[0194] Get the white TiO of embodiment 1 2 Nanobubbles, the ethanol solution of APTES (3-aminopropyltriethoxysilane) was added dropwise to the white TiO 2 In the ethanol of the nanobubbles, the reaction was stirred for 24 hours to aminate the surface of the nanocomposite. After the reaction, centrifuge at 12,000 rpm for 30 minutes to remove excess reaction by-products in the supernatant to obtain aminated white TiO 2 nanobubbles. Disperse the above product in MES (pH 8.0), slowly drop it into CPCC-COOH lipid microbubbles, incubate gently on ice for 2 hours, move to a 4°C refrigerator and continue to incubate for 24 hours to obtain lipid microbubbles / white TiO 2 Covalently bonded composites of nanobubbles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com