Method for recycling sylvinite by using carnallite decomposition mother liquor

A technology for decomposing mother liquor and carnallite, which is applied in the preparation of alkali metal halide shapes, alkali metal chlorides, etc., can solve the problems such as the inability to handle the decomposing mother liquor and the undisclosed processing of the carnallite decomposing mother liquor, etc., and achieves good economic value and Appreciation space, saving water resources and energy consumption, easy operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

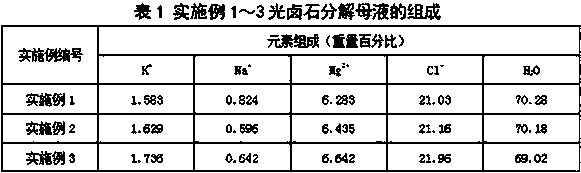

Embodiment 1

[0021] This embodiment includes the following steps:

[0022] (1) Preheating: Preheat the carnallite decomposition mother liquor to 75℃, and divide the preheated carnallite decomposition mother liquor into carnallite decomposition mother liquor I and carnallite decomposition mother liquor II. The carnallite decomposition mother liquor I accounts for light 27.8% of the total mass of carnallite decomposition mother liquor, carnallite decomposition mother liquor II accounted for 72.2% of the total mass of carnallite decomposition mother liquor;

[0023] The mother liquor of carnallite decomposition is the liquid phase produced by cold decomposition of carnallite, which is KCl, NaCl, MgCl 2 The three-phase total saturated solution (may also contain other trace elements).

[0024] (2) Preparation of artificial carnallite by evaporation and crystallization: continue heating the carnallite decomposition mother liquor II obtained in step (1) to boiling, and control the amount of evaporated w...

Embodiment 2

[0030] This embodiment includes the following steps:

[0031] (1) Preheating: Preheat the carnallite decomposition mother liquor to 78℃, and divide the preheated carnallite decomposition mother liquor into carnallite decomposition mother liquor I and carnallite decomposition mother liquor II, and the carnallite decomposition mother liquor I accounts for light 26.5% of the total mass of the carnallite decomposition mother liquor, and the carnallite decomposition mother liquor II accounts for 73.5% of the total mass of the carnallite decomposition mother liquor;

[0032] The mother liquor of carnallite decomposition is the liquid phase produced by cold decomposition of carnallite, which is KCl, NaCl, MgCl 2 The three-phase total saturated solution (may also contain other trace elements).

[0033] (2) Preparation of artificial carnallite by evaporation and crystallization: continue heating the carnallite decomposition mother liquor II obtained in step (1) to boiling, and control the amo...

Embodiment 3

[0039] This embodiment includes the following steps:

[0040] (1) Preheating: preheat the carnallite decomposition mother liquor to 72℃, and divide the preheated carnallite decomposition mother liquor into carnallite decomposition mother liquor I and carnallite decomposition mother liquor II, and the carnallite decomposition mother liquor I accounts for light 30% of the total mass of the carnallite decomposition mother liquor, and the carnallite decomposition mother liquor II accounts for 70% of the total mass of the carnallite decomposition mother liquor;

[0041] The mother liquor of carnallite decomposition is the liquid phase produced by cold decomposition of carnallite, which is KCl, NaCl, MgCl 2 The three-phase total saturated solution (may also contain other trace elements).

[0042] (2) Preparation of artificial carnallite by evaporation and crystallization: continue heating the carnallite decomposition mother liquor II obtained in step (1) to boiling, and control the amount ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com