Preparation method of graphite-ball-enhanced aluminium-based composite material with high heat-conductivity isotropy

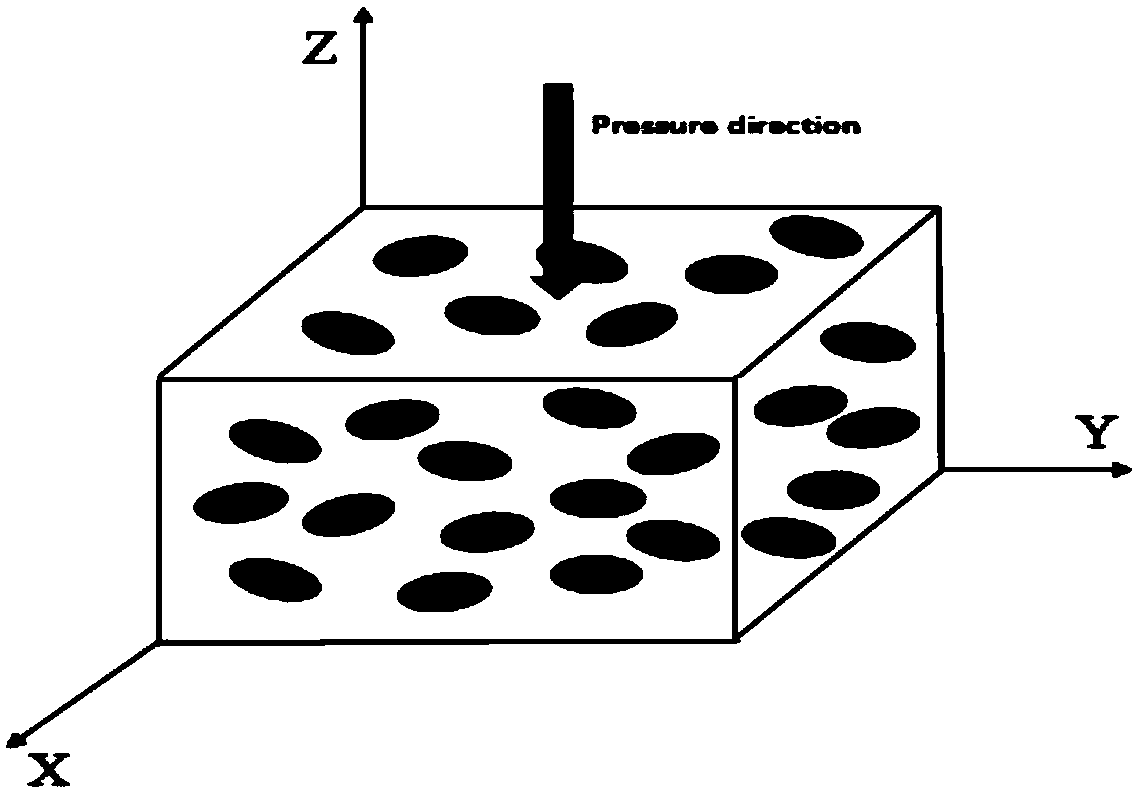

An aluminum-based composite material and a composite material technology are applied in the field of graphite ball-aluminum-based composite materials and their preparation, which can solve the problems of high anisotropy of thermal conductivity, achieve low thermal expansion performance, simple and reliable preparation method, and thermal conductivity. Good rate isotropy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1: Preparation of graphite ball-aluminum matrix composite material at 450 °C

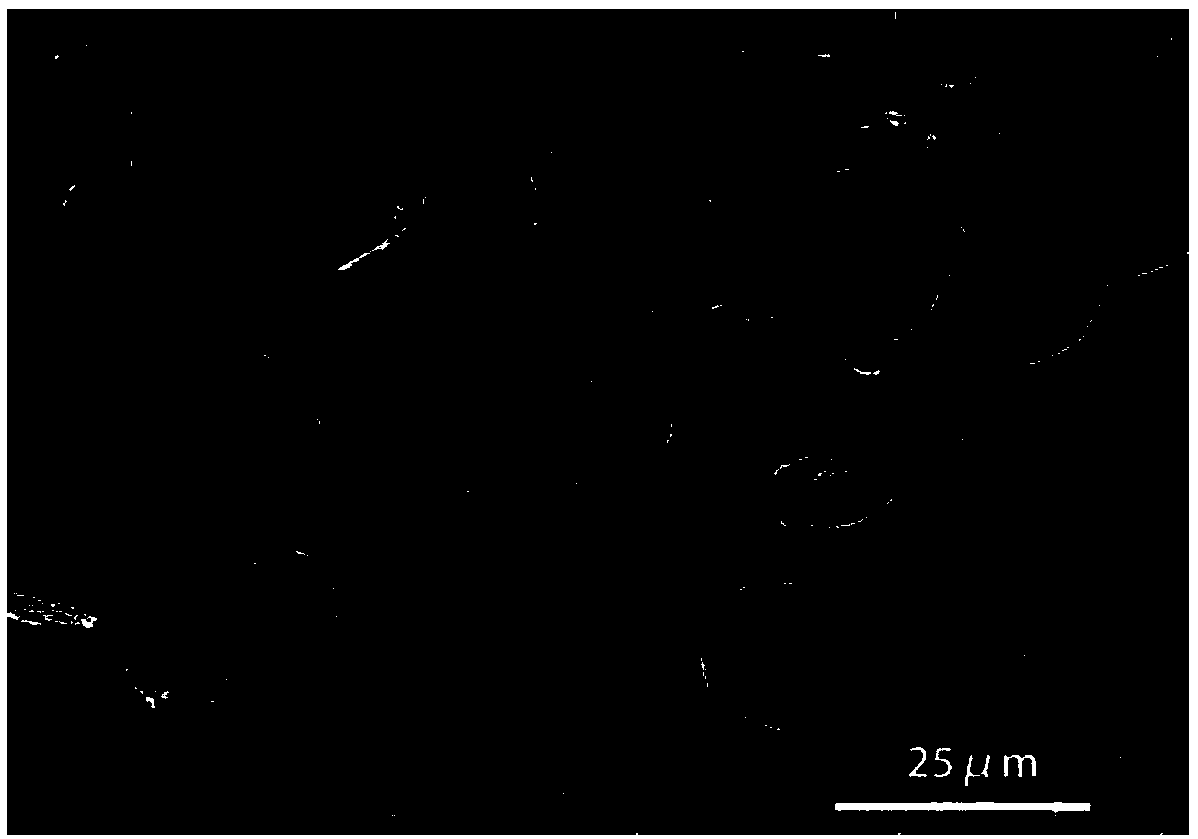

[0019] The graphite balls with an average particle size of 50 μm and the aluminum powder with an average particle size of 48 μm were mechanically mixed according to the set volume ratio, and mixed on a mixer for 6 hours.

[0020] The mechanically mixed powder is loaded into a Φ10mm graphite mold for spark plasma sintering, the sintering pressure is 30MPa, the temperature is raised to 200°C for 5-10 minutes, and the graphite ball-aluminum matrix composite material is obtained by cooling to room temperature with water cooling in the furnace.

Embodiment 2

[0021] Example 2: Preparation of graphite ball-aluminum matrix composite material at 500 °C

[0022] Graphite balls with an average particle size of 50 μm and pure aluminum powders with an average particle size of 48 μm were mechanically mixed according to the set volume ratio, and mixed on a mixer for 6 hours.

[0023] The mechanically mixed powder is loaded into a Φ10mm graphite mold for spark plasma sintering, the sintering pressure is 30MPa, the temperature is raised to 350°C for 5-10 minutes, and the graphite ball-aluminum matrix composite material is obtained by cooling to room temperature with water cooling in the furnace.

Embodiment 3

[0024] Example 3: Preparation of graphite ball-aluminum matrix composite material at 550 °C

[0025] Graphite balls with an average particle size of 50 μm and pure aluminum powders with an average particle size of 48 μm were mechanically mixed according to the set volume ratio, and mixed on a mixer for 6 hours.

[0026] The mechanically mixed powder is loaded into a Φ10mm graphite mold for spark plasma sintering, the sintering pressure is 30MPa, the temperature is raised to 400°C for 5-10 minutes, and the graphite ball-aluminum matrix composite material is obtained by cooling to room temperature with water cooling in the furnace.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com