Electrochemical power source diaphragm and preparation method thereof, and electrochemical cell or capacitor

An electrochemical and diaphragm technology, applied in the field of electrochemistry, can solve the problems of poor electrolyte wetting performance, uneven distribution, low heat resistance temperature, etc., to meet the packaging and cycle performance, overcome uneven distribution, and high film breaking temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A preparation method of an electrochemical power separator, comprising the following steps:

[0029] (1) Anhydrous aluminum chloride is dissolved in deionized water to prepare an aluminum chloride solution with a mass concentration of 20%;

[0030] (2) After immersing the PET non-woven fabric with a thickness of 15 μm in the aluminum chloride solution in (1) for 1 hour, take it out to obtain the PET non-woven fabric with the aluminum chloride solution attached to the surface;

[0031] (3) Arrange the above-mentioned PET nonwoven with aluminum chloride solution in an ammonia environment for 1 hour, take it out after the reaction of aluminum chloride is complete, wash it with deionized water until the pH test is neutral, and then place it at 80 ℃ drying oven for 24 hours and then take it out to obtain a PET non-woven electrochemical power separator coated with aluminum hydroxide.

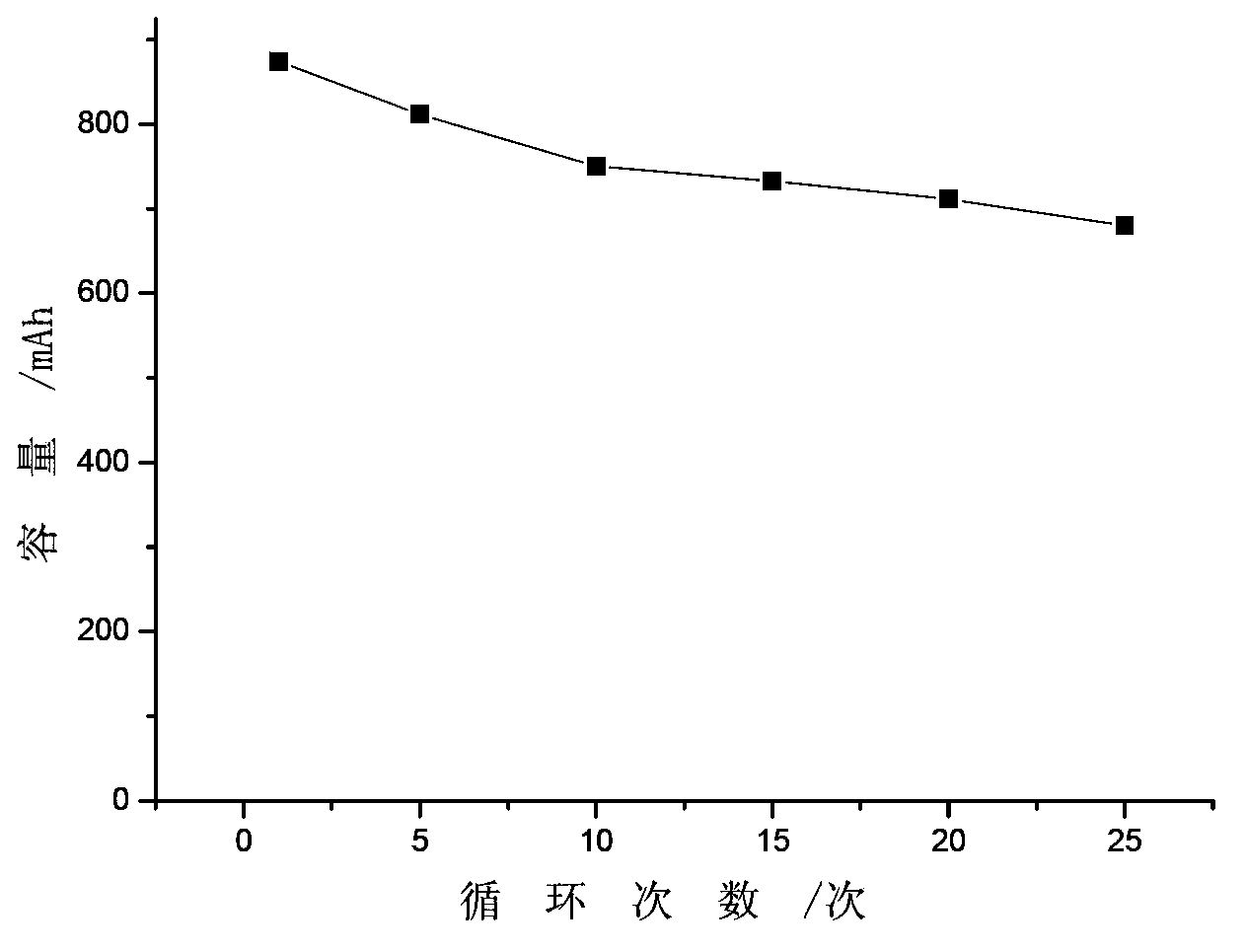

[0032] The electrochemical power supply separator prepared in this embodiment was measured...

Embodiment 2

[0034] A preparation method of an electrochemical power separator, comprising the following steps:

[0035] (1) Anhydrous aluminum chloride is dissolved in ethanol to prepare an aluminum chloride ethanol solution with a mass concentration of 25%;

[0036] (2) Immerse the PAN non-woven fabric with a thickness of 20 μm in the aluminum chloride ethanol solution in (1) for 2 hours, take it out, and obtain the PAN non-woven fabric with the aluminum chloride solution attached to the surface;

[0037] (3) Arrange the above-mentioned nonwoven with aluminum chloride solution in an ammonia atmosphere for 2 hours, take it out after the aluminum chloride has completely reacted, wash it with deionized water until the pH test is neutral, and then place it at 100°C Take it out after drying in a drying oven for 16 hours to obtain a non-woven electrochemical power separator coated with aluminum hydroxide.

[0038] The electrochemical power supply separator prepared in this embodiment was meas...

Embodiment 3

[0040] A preparation method of an electrochemical power separator, comprising the following steps:

[0041] (1) Anhydrous aluminum chloride is dissolved in ether to prepare an aluminum chloride ether solution with a mass concentration of 50%;

[0042] (2) Immerse the PAN non-woven fabric with a thickness of 10 μm in the aluminum chloride solution in (1) for 2 hours, take it out, and obtain the PAN non-woven fabric with the aluminum chloride solution attached to the surface;

[0043] (3) Arrange the above-mentioned PAN non-woven with aluminum chloride solution in an ammonia environment for 2 hours, take it out after the reaction of aluminum chloride is complete, wash it with deionized water until the pH test is neutral, and then place it at 70 ℃ drying oven for 20 hours and then take it out to obtain a PAN non-woven electrochemical power separator coated with aluminum hydroxide.

[0044] The electrochemical power supply separator prepared in this embodiment was measured for po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com