Device and method for correcting secondary harmonic waveform of photoacoustic system and increasing precision

A second harmonic, photoacoustic technology, applied in measurement devices, color/spectral property measurement, material analysis by optical means, etc. Improve signal-to-noise ratio, low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

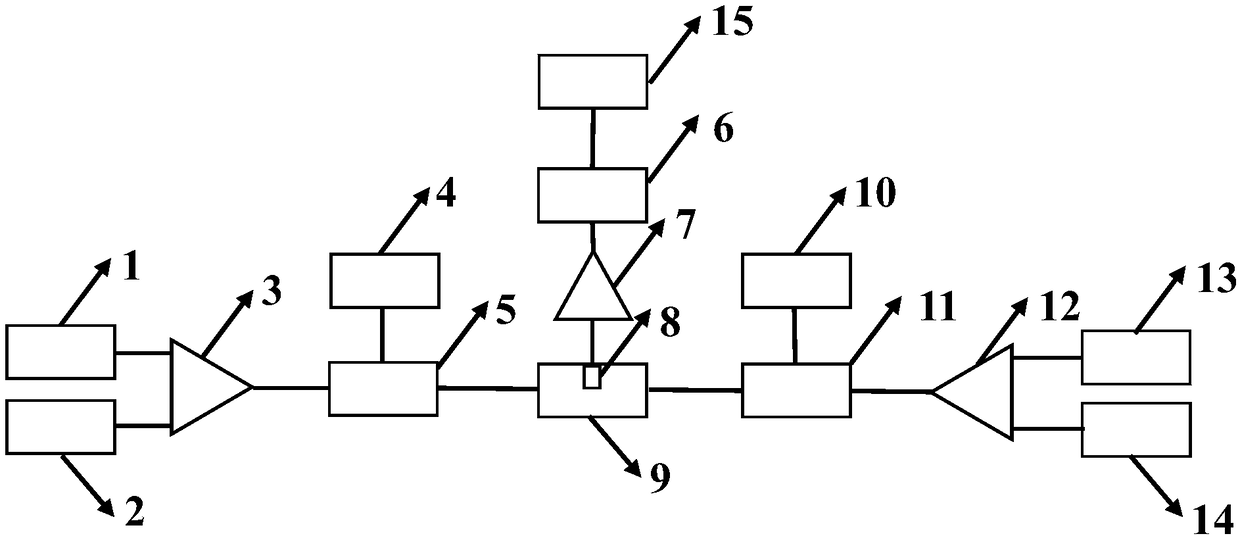

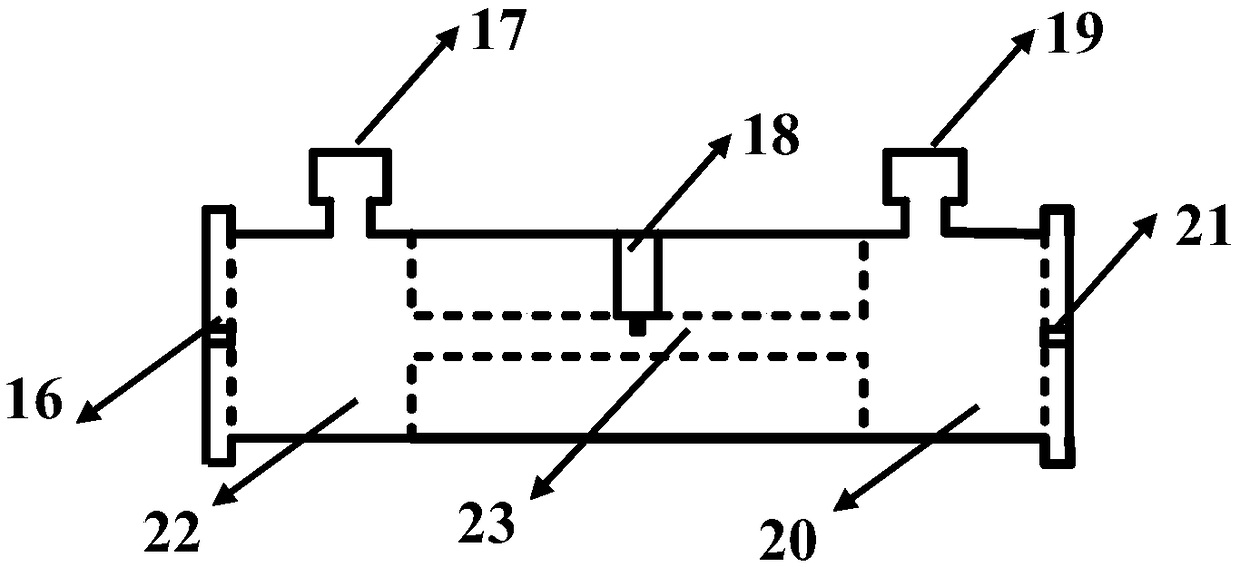

[0029] A device for correcting the second harmonic waveform of a photoacoustic system and improving accuracy, such as figure 1 As shown, it includes microcontroller a1, signal generator a2, adder a3, temperature control module a4, DFB laser a5, lock-in amplifier 6, preamplifier 7, microphone 8, photoacoustic pool 9, temperature control module b10, DFB laser b11, adder b12, single-chip microcomputer b13, signal generator b14 and computer 15, the output terminals of single-chip microcomputer a1 and signal generator a2 are respectively connected to the two input terminals of adder a4, the output of adder a3 and temperature control module a4 terminals are respectively connected to the DFB laser a5; the output terminals of the single chip microcomputer b13 and the signal generator b14 are respectively connected to the two input terminals of the adder b12, and the output terminals of the adder b12 and the temperature control module b10 are respectively connected to the DFB laser b11;...

Embodiment 2

[0032] A kind of method that utilizes above-mentioned device to work, the steps are as follows:

[0033] 1) Connect the above devices, turn on the single-chip microcomputer a2, the signal generator a3, the single-chip microcomputer b13, the signal generator b14 and the power supply of the computer 15, and inject the gas to be measured containing acetylene in the photoacoustic cell 9;

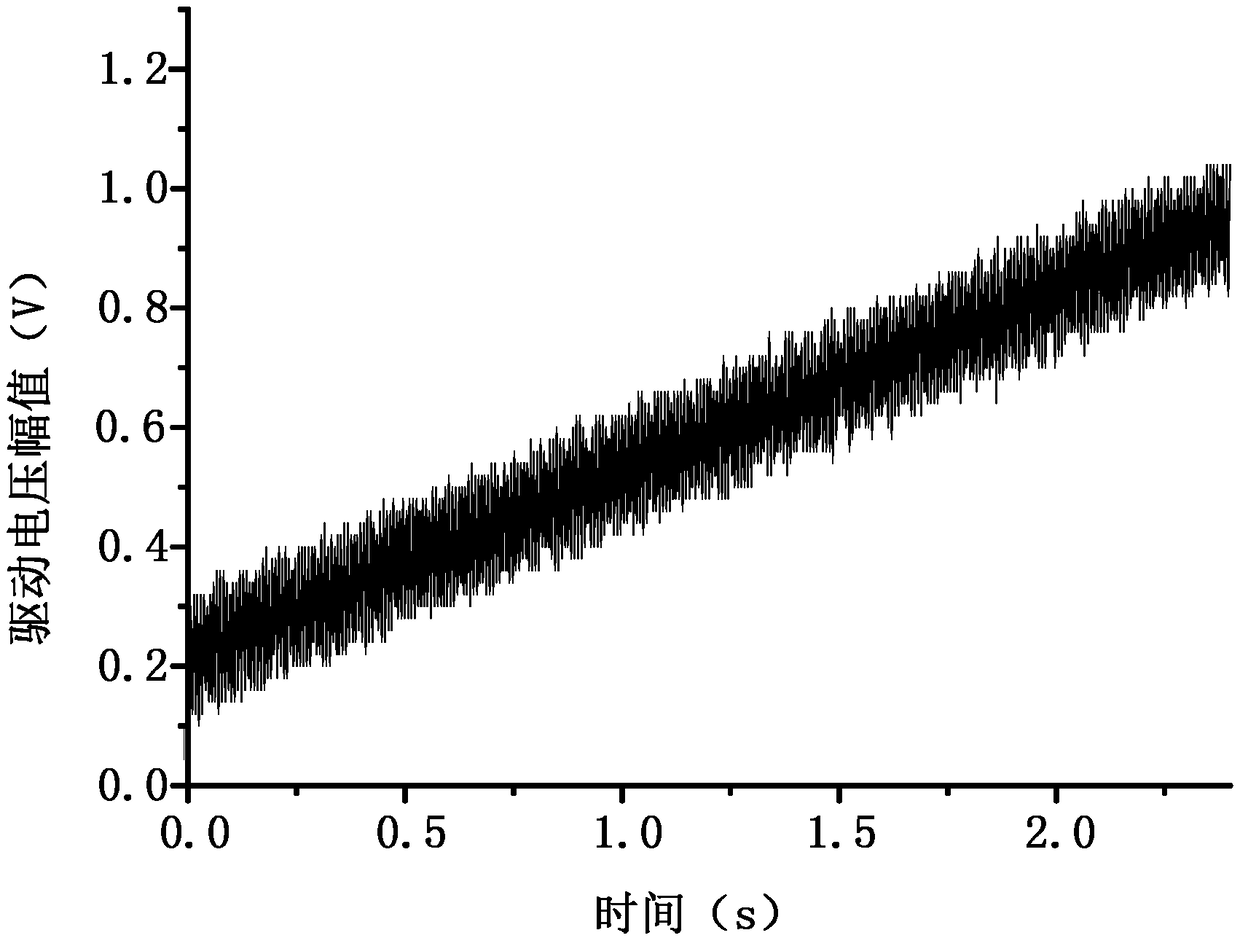

[0034] 2) Let the single-chip microcomputer a2 generate a sawtooth wave as a low-frequency scanning signal, and the single-chip microcomputer b13 generate an anti-sawtooth wave as a low-frequency scanning signal, and the signal generator a2 and the signal generator b14 generate a high-frequency modulation signal that is half the resonant frequency of the photoacoustic cell 9. After The adder a4 and the adder b12 add the scanning signal and the modulation signal as the driving signal, such as image 3 and 4 not;

[0035] 3) Turn on the power supply of the DFB laser a5, observe the position of t...

Embodiment 3

[0040] Same as Example 2, except that the gas to be measured is the gas to be measured containing water vapor, and the central wavelength of the DFB laser corresponds to the absorption peak of water vapor at 1368.597 nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com