Industrial robot in mechanical manufacturing workshop and using method of industrial robot

A technology of industrial robots and production workshops, applied in the field of robotics, can solve problems that are difficult to solve manually, achieve the effect of improving precision, improving work efficiency and precision, and avoiding difficulties and hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

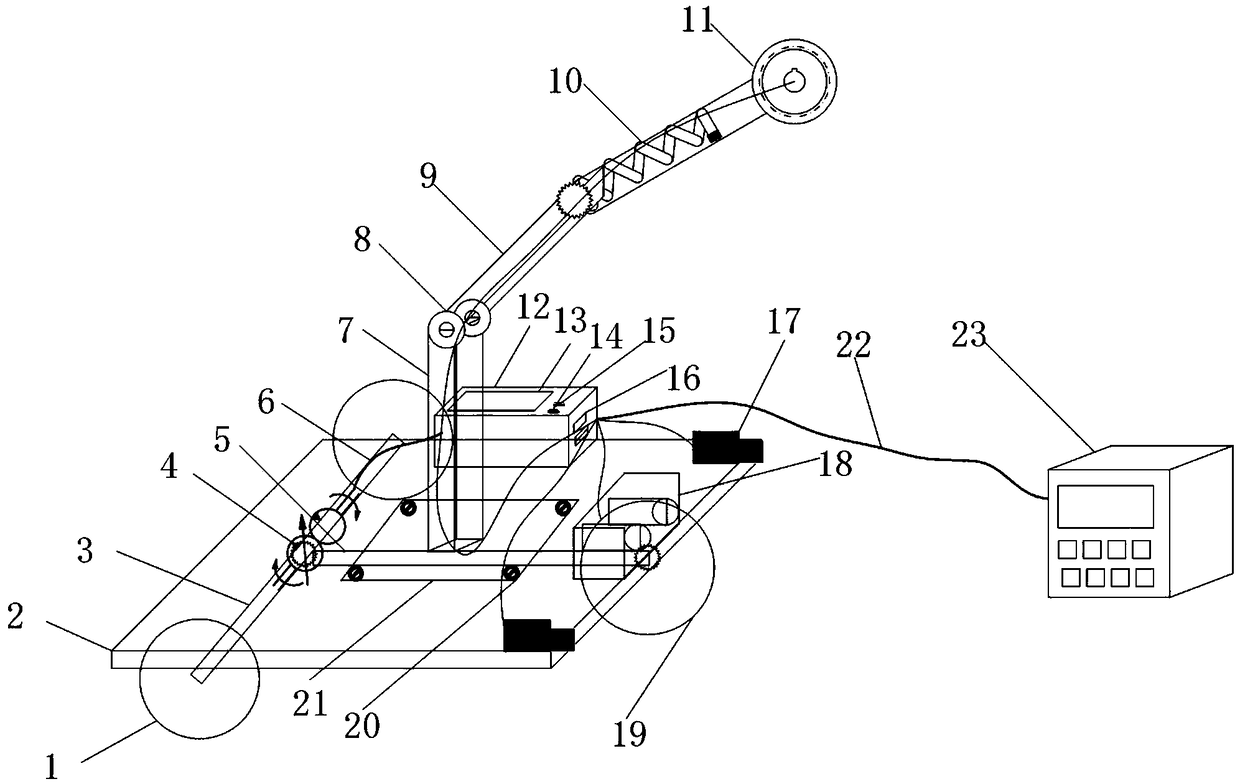

[0024] Such as figure 1 The industrial robot used in a mechanical production workshop includes a rear drive rubber wheel 1, an acrylic base plate 2, a rear drive shaft 3, a drive shaft 4, a shaft coupling 5, a drive signal line 6, a support frame 7, a bearing 8, One-word bracket 9, telescopic bracket 10, cutting wheel 11, controller 12, display screen 13, switch 14, button 15, data port 16, infrared pair tube 17, CCD camera 18, front drive rubber wheel 19, positioning screw 20, support Board 21, transmission line 22, PC terminal 23, characterized in that the acrylic base plate 2 is a square base plate made of acrylic, the rear drive rubber wheel 1 is rotationally connected with the rear drive shaft 3, and the rear drive shaft 3 The formed axisymm...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap