Durable porcelain and production technology thereof

A production process and a technology of strengthening porcelain, which is applied in the production of ceramic materials, other household appliances, applications, etc., can solve the problems of impact resistance, low impact resistance, cracking, glaze smoothness and gloss, and improve quality , Improve adhesion, improve gloss and feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

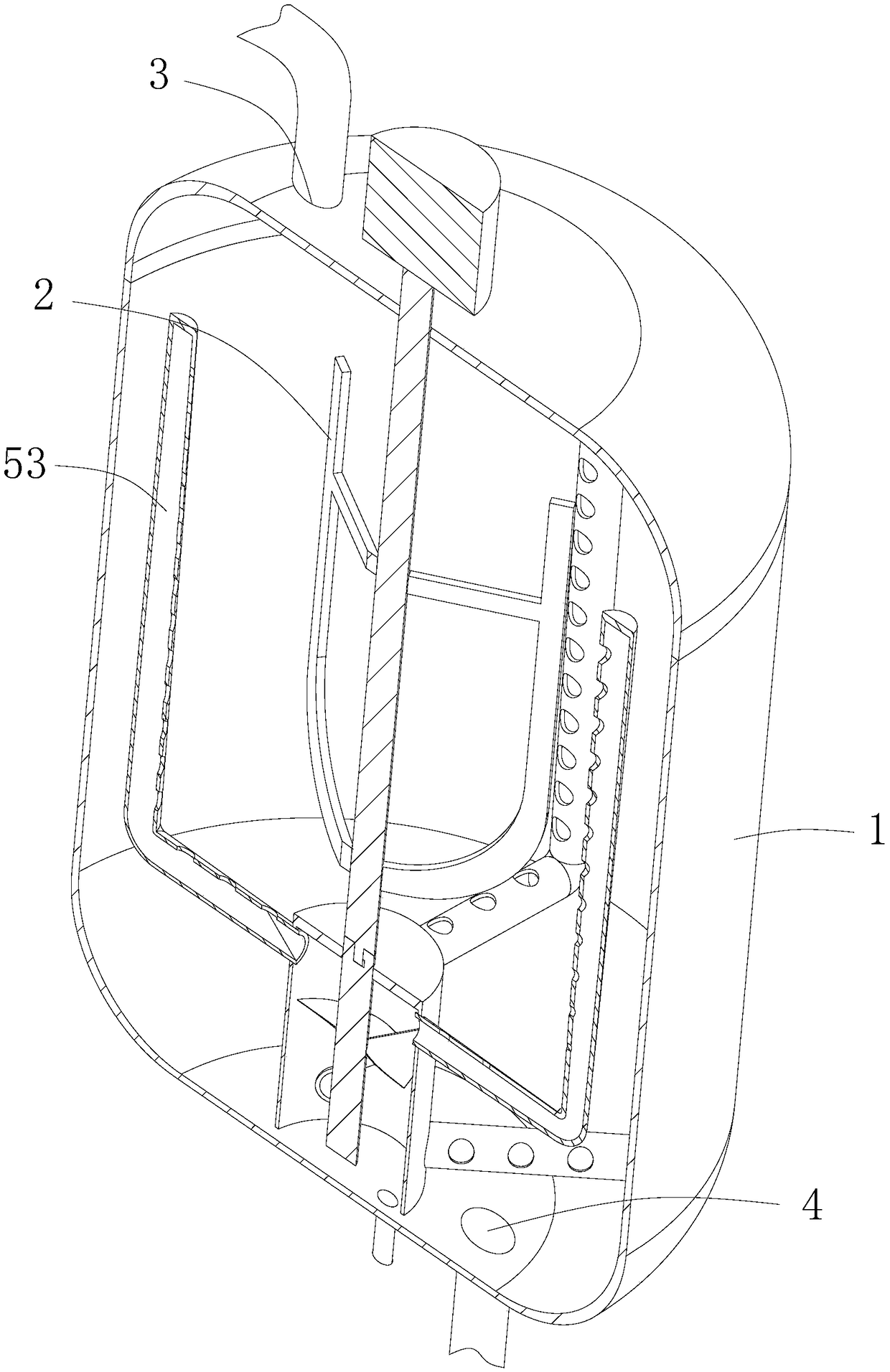

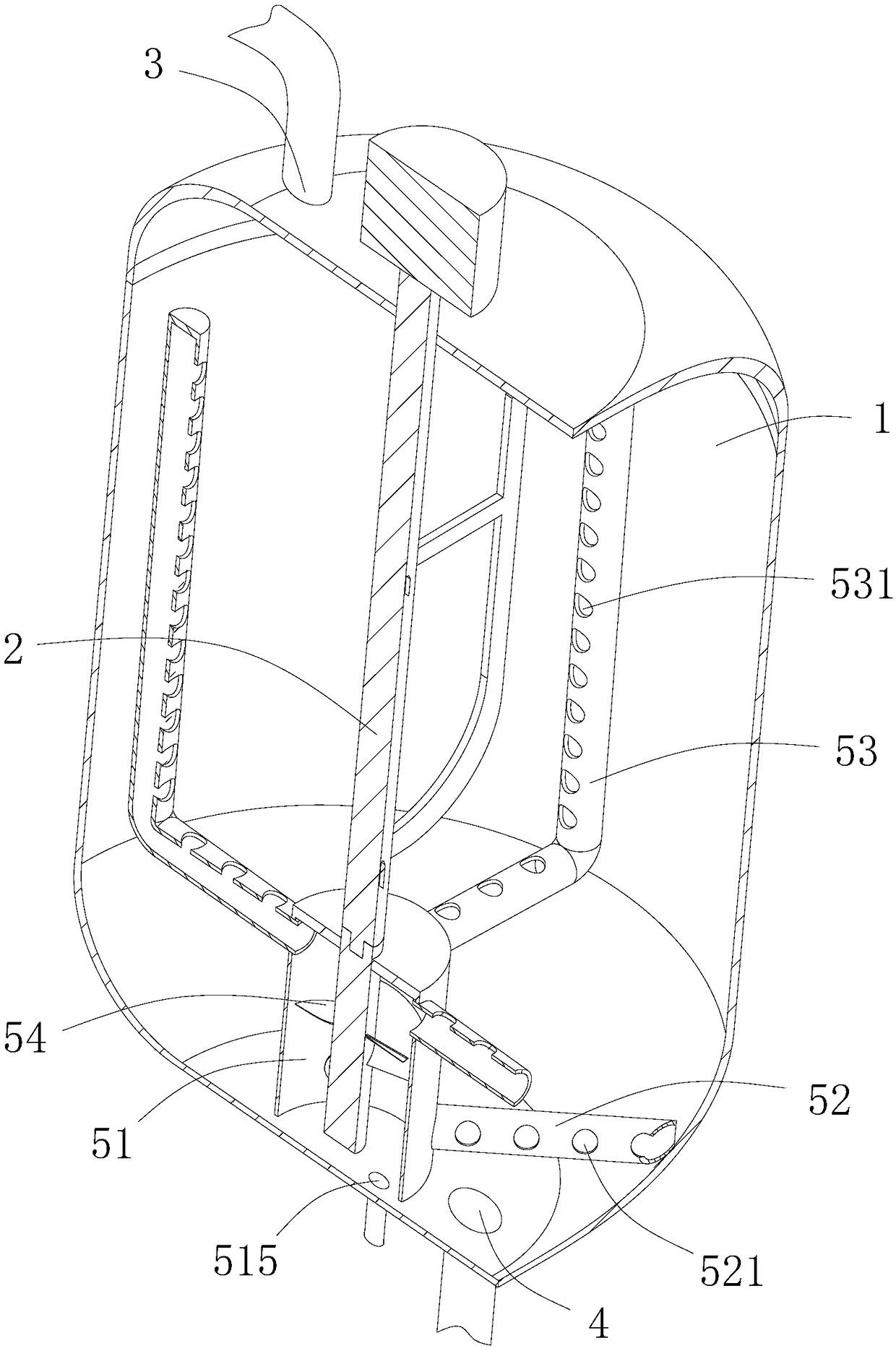

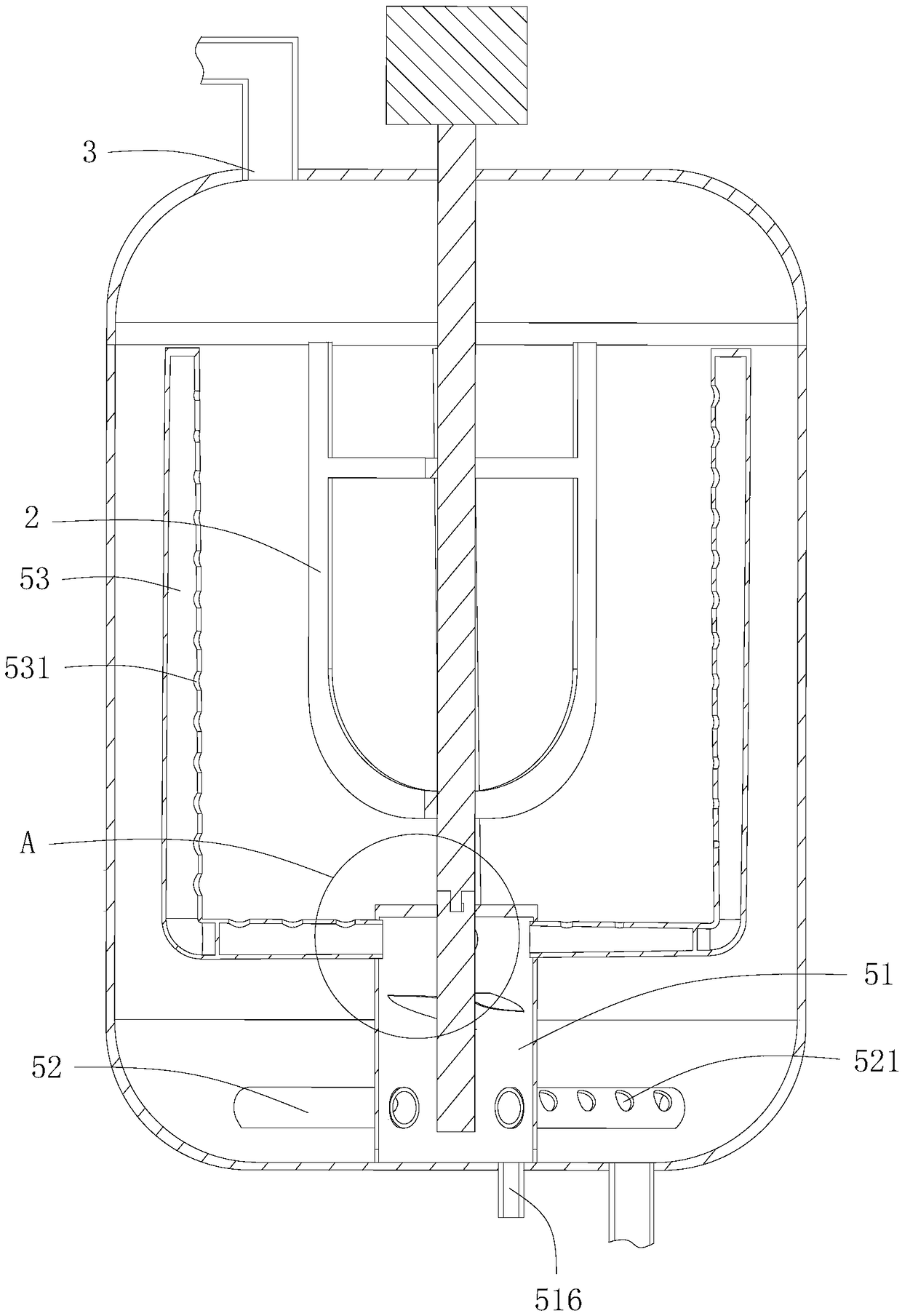

Image

Examples

Embodiment 1

[0039] A reinforced porcelain and its production process. The blank of the reinforced porcelain comprises the following components in parts by weight: 50 parts of magnesia stone powder, 30 parts of feldspar powder, 35 parts of Xiaomei Gaojitou porcelain clay, 32 parts of Anfu porcelain clay, and 26 parts of waste ceramic powder Parts, 24 parts of waste glass powder, 12 parts of dolomite, 6 parts of barium carbonate; the glaze includes the following components in parts by weight: 60 parts of glaze fruit, 25 parts of kaolin, 20 parts of dolomite, 8 parts of penetrating feldspar , 3 parts of boric acid; wherein the particle size of the waste ceramic powder is 20um, and the particle size of the waste glass is 25um.

[0040] The production process of the above-mentioned strengthened porcelain includes the following steps: (1) Weighing the raw materials: weighing magnesia stone, feldspar, Xiaomei Gaojitou porcelain clay, Anfu porcelain clay, waste ceramics, waste glass according to the ...

Embodiment 2

[0052] A reinforced porcelain and its production process. The blank of the reinforced porcelain includes the following components in parts by weight: 30 parts of magnesium stone powder, 25 parts of feldspar powder, 28 parts of Xiaomei Gaojitou porcelain clay, 26 parts of Anfu porcelain clay, and 22 parts of waste ceramic powder Parts, 16 parts of waste glass powder, 5 parts of dolomite, 3 parts of barium carbonate; the glaze includes the following components in parts by weight: 30 parts of glaze fruit, 20 parts of kaolin, 10 parts of dolomite, 5 parts of permeable feldspar , 6 parts of boric acid; wherein the particle size of the waste ceramic powder is 10um, and the particle size of the waste glass is 15um.

[0053] The production process of the above-mentioned reinforced porcelain includes the following steps: (1) Weighing the raw materials: weighing magnesia stone, feldspar, Xiaomei Gaojitou porcelain clay, Anfu porcelain clay, waste ceramics, and waste glass according to the w...

Embodiment 3

[0056] A reinforced porcelain and its production process. The blank of the reinforced porcelain includes the following components in parts by weight: 50 parts of magnesia stone powder, 30 parts of feldspar powder, 35 parts of Xiaomei Gaojitou porcelain clay, 28 parts of Anfu porcelain clay, and 24 parts of waste ceramic powder Parts, 18 parts of waste glass powder, 8 parts of dolomite, 3 parts of barium carbonate; the glaze includes the following parts by weight: 50 parts of glaze fruit, 20 parts of kaolin, 15 parts of quartz, 10 parts of dolomite, lithium permeable 8 parts of feldspar and 3 parts of boric acid; wherein the particle size of the waste ceramic powder is 15um, and the particle size of the waste glass is 18um.

[0057] The production process of the above-mentioned strengthened porcelain includes the following steps: (1) Weighing the raw materials: weighing magnesia stone, feldspar, Xiaomei Gaojitou porcelain clay, Anfu porcelain clay, waste ceramics, waste glass accor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com