Seamless tunnel structure adopting ECC concrete post-cast strips and construction method of seamless tunnel structure

A technology of tunnel structure and post-casting zone, applied in tunnels, tunnel linings, earthwork drilling, etc., can solve the problems of easy cracking of the secondary lining of the tunnel, easy cracking and corrosion of the water stop belt, etc., so as to solve the problem of water leakage. , to avoid cracking, to avoid the effect of large cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

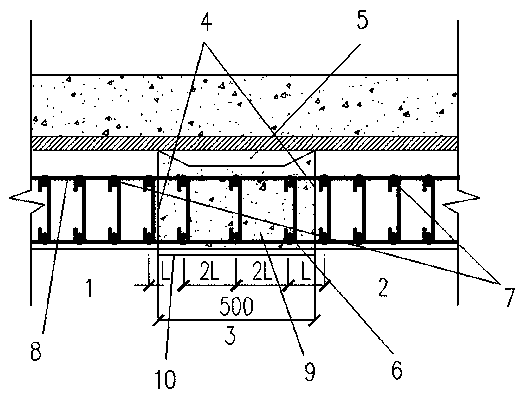

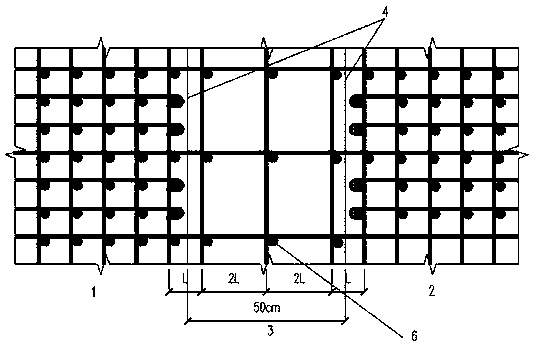

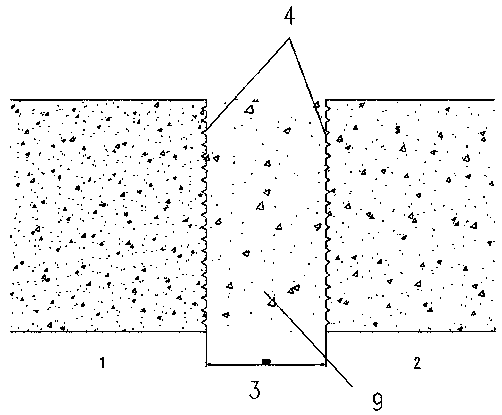

[0038] Embodiment 1: as Figure 1-9As shown, the seamless tunnel structure using the ECC concrete post-cast belt includes the secondary lining poured in stages in advance, the post-cast belt 3, the circumferential blind ditch 5, the post-cast belt reinforcement 6, the pre-cast secondary lining concrete Reinforcement 7, connecting main reinforcement 8, ECC concrete 9; when performing the secondary lining 1 of the previous section and the secondary lining 2 of the subsequent section, the concrete poured in advance shall be reinforced according to the design requirements, and at the same time, pre-poured The connecting main reinforcement 8 is reserved, and the density of the reserved connecting main reinforcement 8 is lower than that of the secondary lining concrete reinforcement 7 poured in advance; after the final setting of the secondary lining in the front and rear sections of the previous segmental pouring is completed, the ECC concrete and ordinary concrete The interface 4 ...

Embodiment 2

[0052] Embodiment 2: as Figure 1-9 As shown, the seamless tunnel structure and its construction method using ECC concrete post-casting belt, this embodiment is the same as embodiment 1, wherein,

[0053] Further, the sub-section length of the former secondary lining 1 and the rear secondary lining 2 is 8m, and the post-casting tape 3 is reserved between two adjacent secondary linings, and the width of the post-casting tape 3 is 80cm.

Embodiment 3

[0054] Embodiment 3: as Figure 1-9 As shown, the seamless tunnel structure and its construction method using ECC concrete post-casting belt, this embodiment is the same as embodiment 1, wherein,

[0055] Further, the sub-section length of the former secondary lining 1 and the rear secondary lining 2 is 6m, and the post-casting tape 3 is reserved between two adjacent secondary linings, and the width of the post-casting tape 3 is 60cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com