Stainless steel water meter shell blank and machining method thereof, stainless steel water meter shell and water meter

A processing method and stainless steel technology are applied in the field of stainless steel water meter shell blanks and processing, and can solve the problems of energy consumption, unfavorable use and life of water meters, and expensive equipment costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

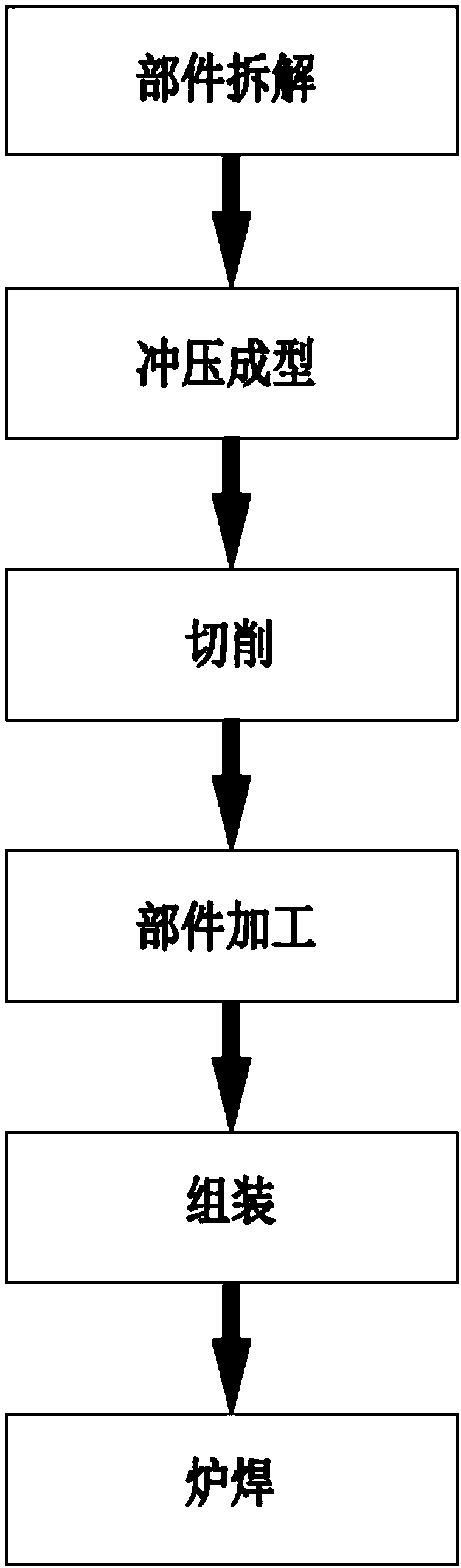

Method used

Image

Examples

Embodiment 1

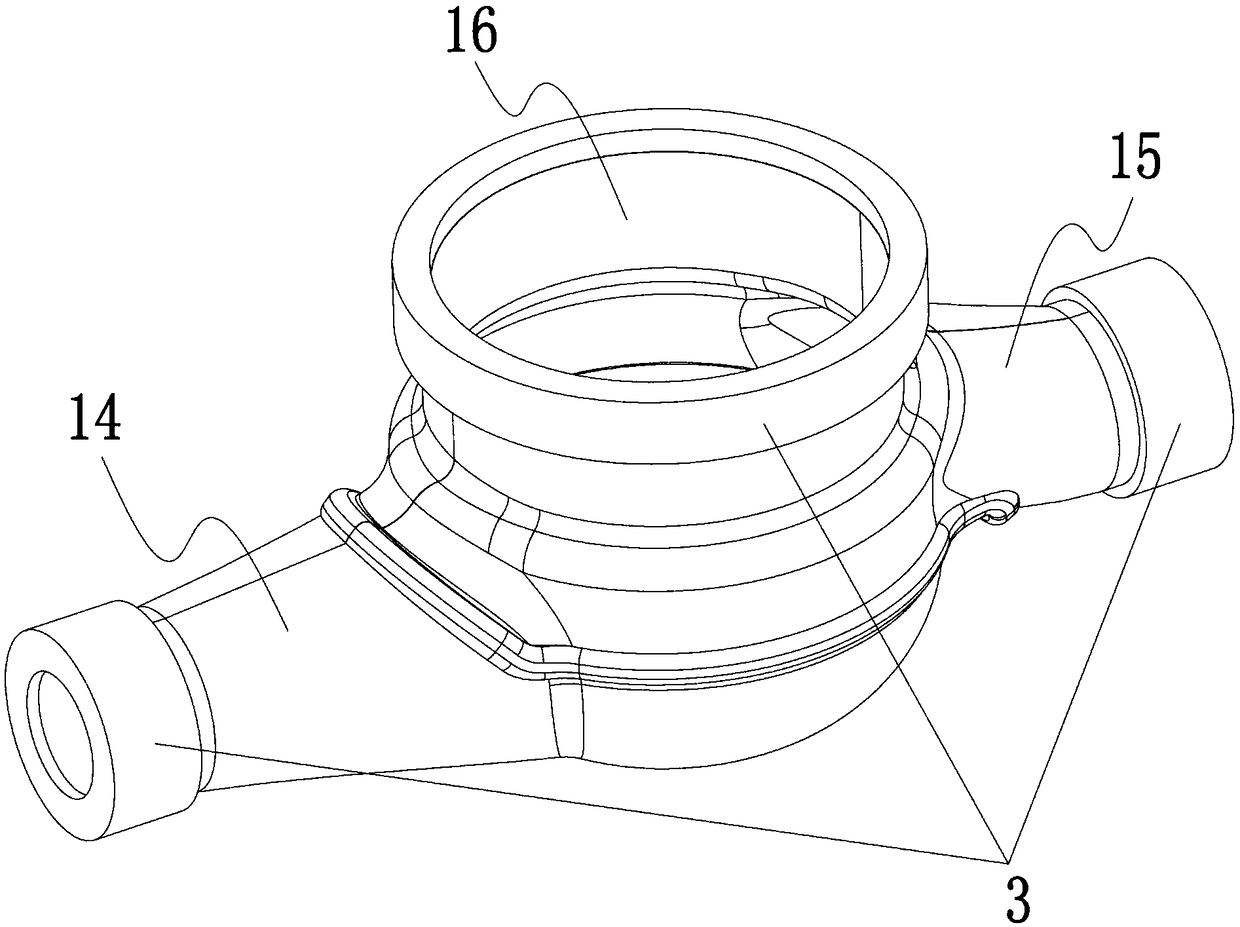

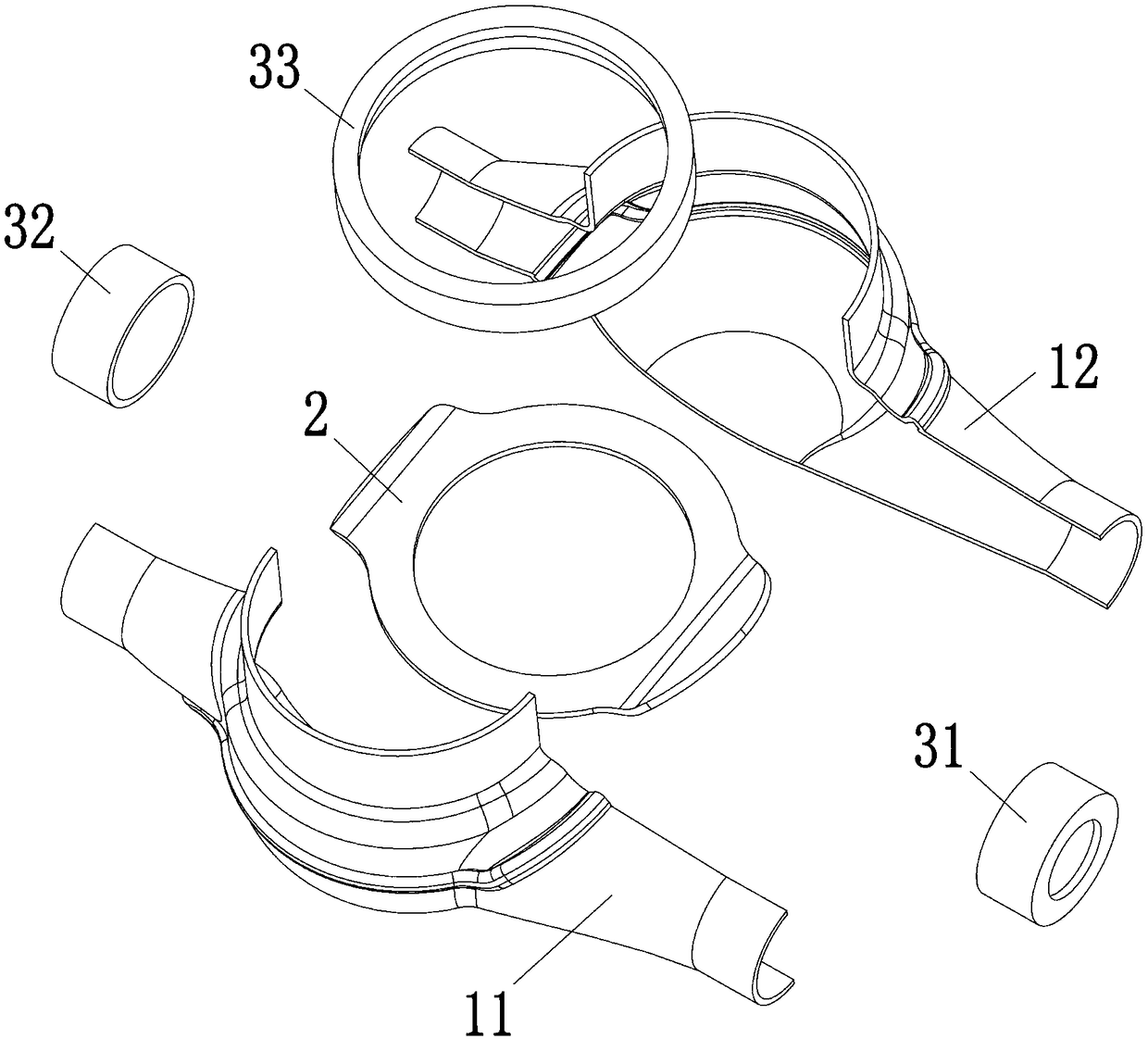

[0070] A stainless steel water meter shell blank structure, which is mainly composed of a shell male piece 11, a shell female piece 12, an inner ring 2 and a brace 3, the brace 3 includes an inlet brace 31, an outlet brace 32 and a case mouth brace 33; The housing male piece 11 and the housing female piece 12 are plane-symmetrical mirror images, and the two cooperate to form the inner cavity structure of the water meter housing, and the junction of the two is a planar structure; the inner cavity includes a cavity 13 , the water inlet channel 14 and the water outlet channel 15, the water inlet channel 14 and the water outlet channel 15 are respectively connected with the cavity 13 to form a water flow channel, the water inlet channel 14 and the water outlet channel 15 are arranged in a straight line, the inlet mouthpiece 31 and the outlet mouthpiece 32 Fitted with the ends of the water inlet channel 14 and the water outlet channel 15 respectively; the cavity 13 is provided with ...

Embodiment 2

[0075] An IC stainless steel water meter casing blank structure, its main structure is the same as the casing blank in Embodiment 1, the difference is that the IC stainless steel water meter casing blank structure also includes a connecting rod valve bracket 4 and a plastic bracket 5 .

[0076] The connecting rod valve bracket 4 is arranged on the water outlet channel 15. At the same time, the valve hole for the connecting rod valve bracket 4 is reserved on the corresponding positions on the housing male piece 11 and the housing female piece 12 during stamping and forming. 18 for the connecting rod valve bracket 4 to pass through the water outlet channel 15. Moreover, a valve locking groove 17 is also provided at a corresponding position on the inner wall of the water outlet channel 15, so that the connecting rod valve can be well fixed in the water outlet channel 15; more preferably, the valve locking groove 17 is also a It is formed by protruding outward during stamping and ...

Embodiment 3

[0080] A vertical stainless steel water meter shell blank structure, its main structure is the same as that of the shell blank in Embodiment 1, the difference is that the water inlet and outlet channels of the shell blank are changed from horizontal to vertical; at the same time, the inner ring 2 is a planar structure as a whole. The specific structure of the vertical stainless steel water meter shell blank is:

[0081] The vertical stainless steel water meter shell blank is composed of a shell male piece 11, a shell female piece 12, an inner ring 2 and a brace 3, and the brace 3 includes an inlet brace 31, an outlet brace 32 and a housing mouth brace 33; the shell The body male piece 11 and the shell female piece 12 are symmetrical mirror images, and the two cooperate to form the inner cavity structure of the water meter housing, and the junction of the two is a planar structure; the inner cavity includes a cavity body 13, a water inlet The channel 14 and the water outlet ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com