Broadband perfect absorber based on metallic film-core shell plasma structure

A plasma and perfect absorption technology, which is applied in the field of perfect absorption materials and its preparation, can solve the problems of high cost and cumbersome process, and achieve the effects of low production cost, controllable area and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] In order to achieve the above object, the present invention also provides a method for manufacturing a broadband perfect absorber based on a metal thin film-core-shell plasma structure. Preferably, the preparation method specifically includes:

[0044] Prepare a chromium film layer on the base ITO;

[0045] Physically depositing a gold film layer on the chromium film layer;

[0046] Deposit a layer of Au@Cu on the upper surface of the gold film layer by liquid-liquid self-assembly method 2 O granular layer;

[0047] Deposit a layer of Au@Cu on the upper surface of the gold film layer by liquid-liquid self-assembly method 2 O granular layer.

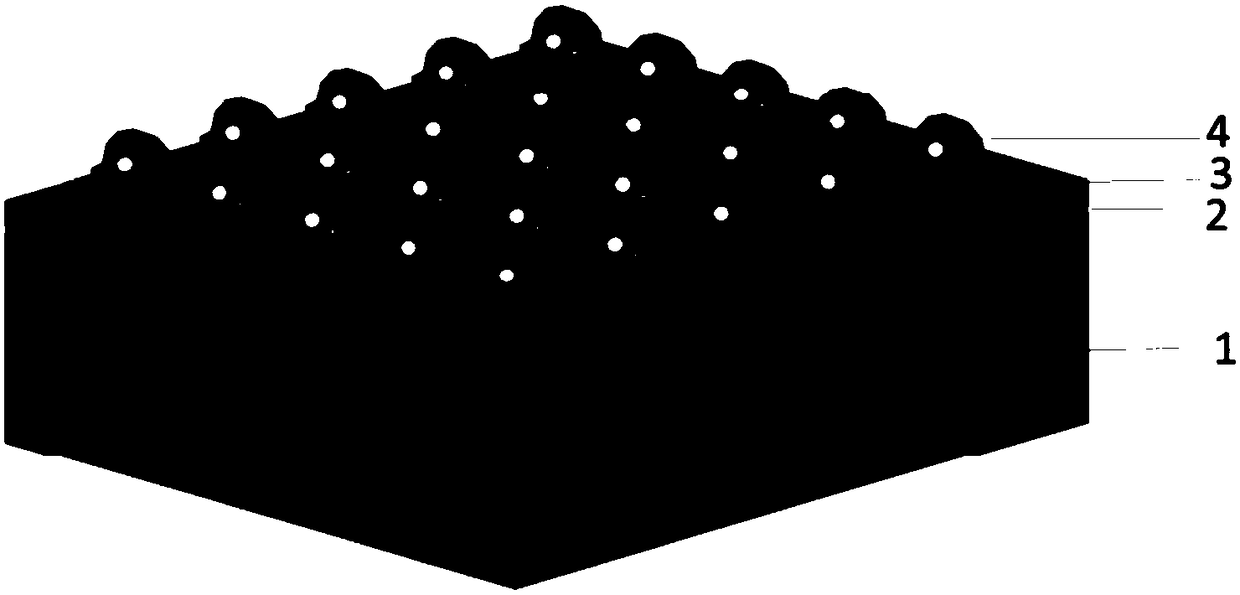

Embodiment 1

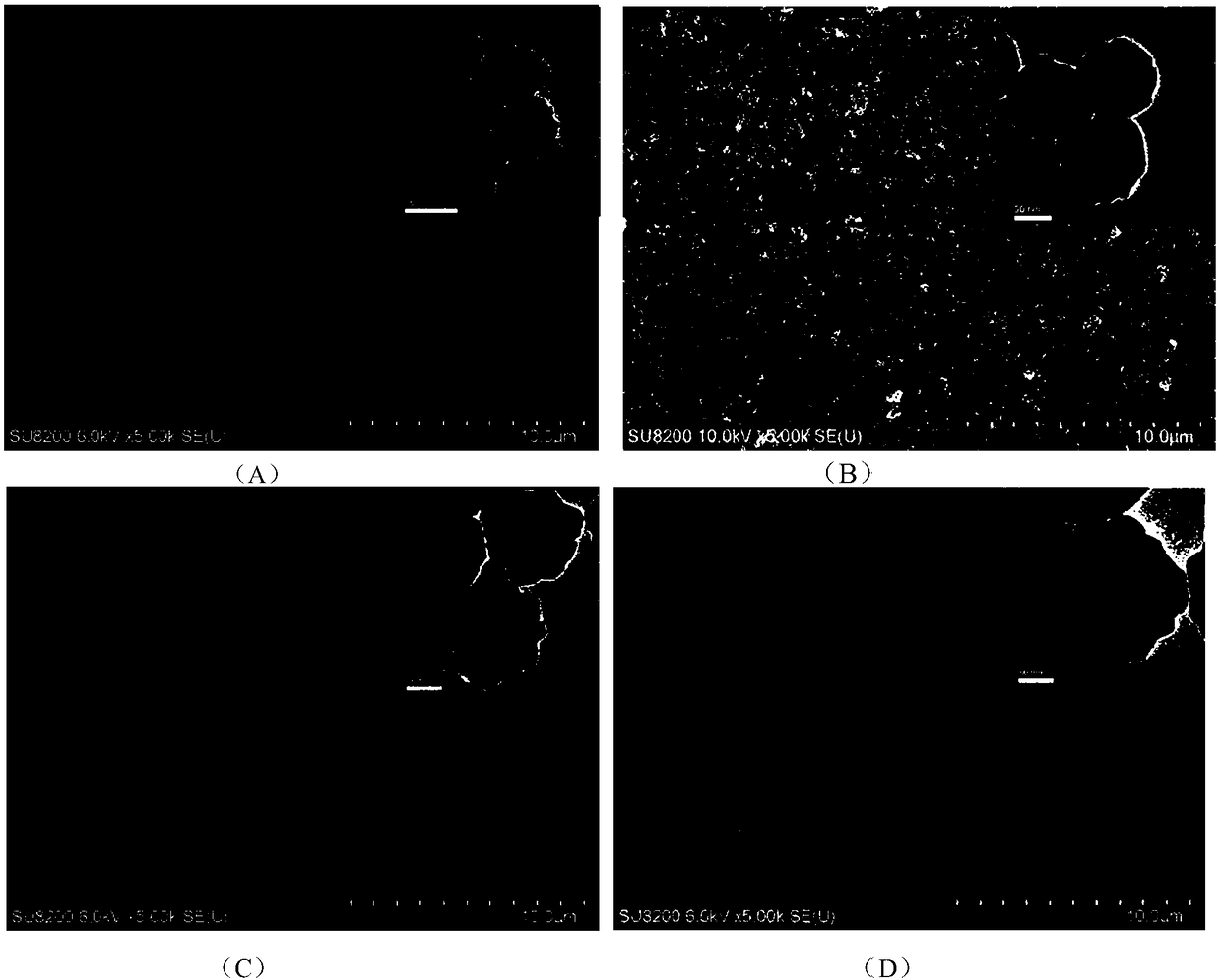

[0050] A broadband perfect absorber based on a metal thin film-core-shell plasma structure, including a substrate, the material of the substrate is ITO, and the substrate 1 is sequentially provided with a chromium film layer, a gold film layer and Au@Cu 2 O structural layer. In this embodiment, the diameter of the core of the core-shell structure is 20 nanometers, and the diameter of the core-shell structure is 50 nanometers (see figure 2 (A)), the core-shell structure film layer is a single layer of Au@Cu 2 O plasmonic nanoparticle core-shell structure particle composition.

[0051] The preparation method of this perfect absorber is:

[0052] A chromium film layer is prepared by vapor deposition on the base ITO, with a thickness of 10 nanometers;

[0053] Physically deposit a gold film layer on the chromium film layer with a thickness of 100 nanometers;

[0054] Deposit a layer of Au@Cu on the upper surface of the gold film layer by liquid-liquid self-assembly method 2 ...

Embodiment 2

[0061] A broadband perfect absorber based on a metal thin film-core-shell plasma structure, including a substrate, the material of the substrate is ITO, and the substrate 1 is sequentially provided with a chromium film layer, a gold film layer and Au@Cu 2 O structural layer. In this embodiment, the diameter of the core of the core-shell structure is 35 nanometers, and the diameter of the core-shell structure is 50-100 nanometers (see figure 2 (B)), the core-shell structure thin film layer is a single layer of Au@Cu 2 O plasmonic nanoparticle core-shell structure particle composition. The preparation process is:

[0062] Preparation of 35nm gold particles: Add 28mL of 20nm gold particles (preparation method is the same as in Example 1) into 75mL of water as gold seed sol, under vigorous stirring, add 0.56mL of 0.2mol / L hydroxylamine hydrochloride solution, and finally add 1mL of 1% Chlorauric acid solution, continue to stir for 30min.

[0063] Au@Cu 2 Preparation of O: 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com