Low-loss single-mode optical fiber and wiredrawing process thereof

A single-mode fiber, low-loss technology, used in clad fibers, glass fibers, multi-layer core/clad fibers, etc., can solve the problems of low strength, low internal stress, and high strength of single-mode fibers, and avoid heat The effect of rapid loss, elimination of residual internal stress and low loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

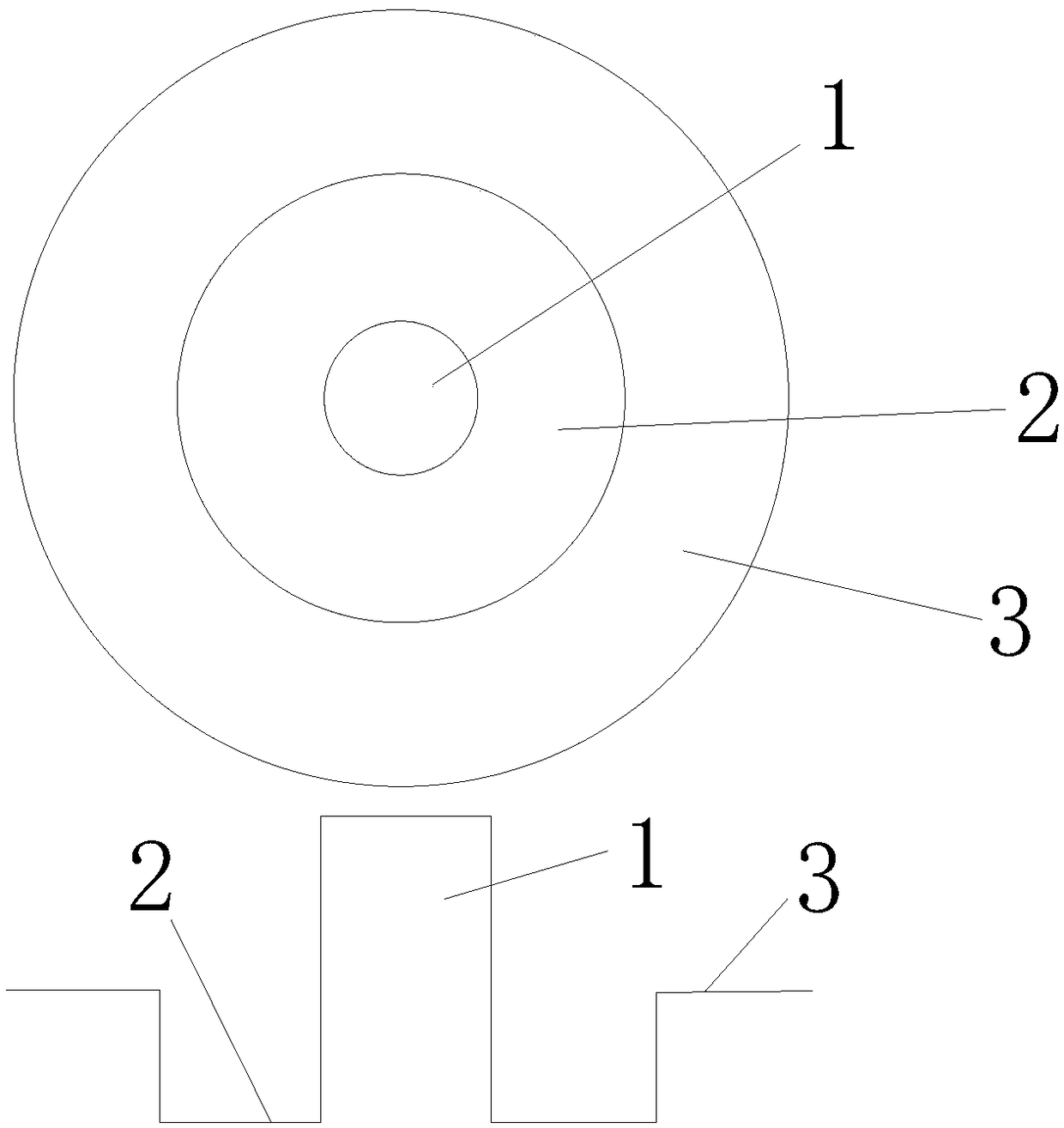

[0029] See figure 1 , this embodiment discloses a low-loss single-mode optical fiber, including a core layer 1, an inner cladding layer 2 and an outer cladding layer 3 arranged in sequence from the inside to the outside, the diameter of the core layer 1 is 7 μm to 8 μm, and the inner cladding layer 2 has a diameter of 15 μm to 25 μm, the core layer 1 is silicon dioxide doped with germanium, the mass fraction of germanium doped in the core layer 1 is 0.05wt% to 0.08wt%, and the refractive index of the core layer 1 is no 1 =1.463~1.467, the positive refractive index difference of the core layer 1 is Δn=﹢0.2%~0.3%, the inner cladding layer 2 is made of fluorine-doped silica, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com