A method for ion-exchanging monolithically integrated magneto-optical waveguides using magnetic nanomaterials

An ion-exchange, monolithic integration technology, applied in optical waveguides, light guides, nonlinear optics, etc., can solve the problems of large absorption of magnetic film optical windows, optical waveguides without magneto-optical performance, and inability to guarantee optical performance, etc. The preparation method is simple and fast, the transmission efficiency of the waveguide is improved, and the effect of avoiding additional loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

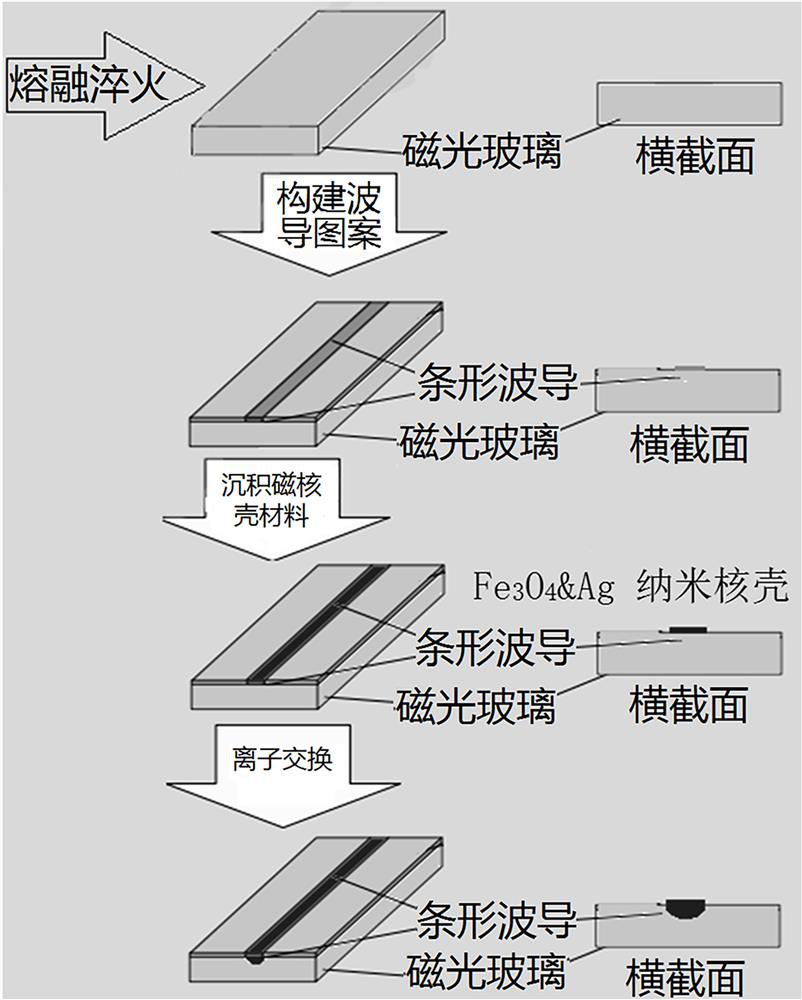

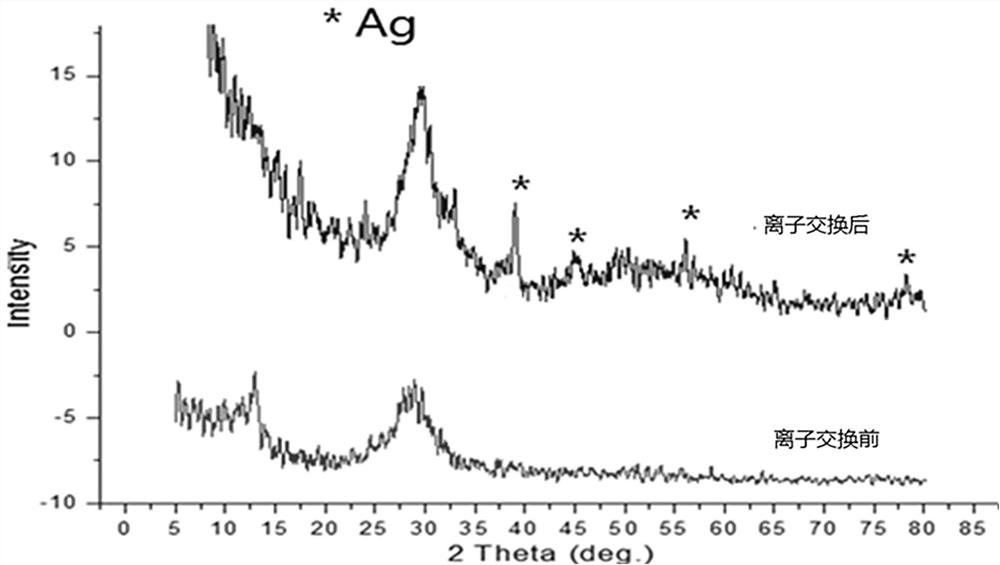

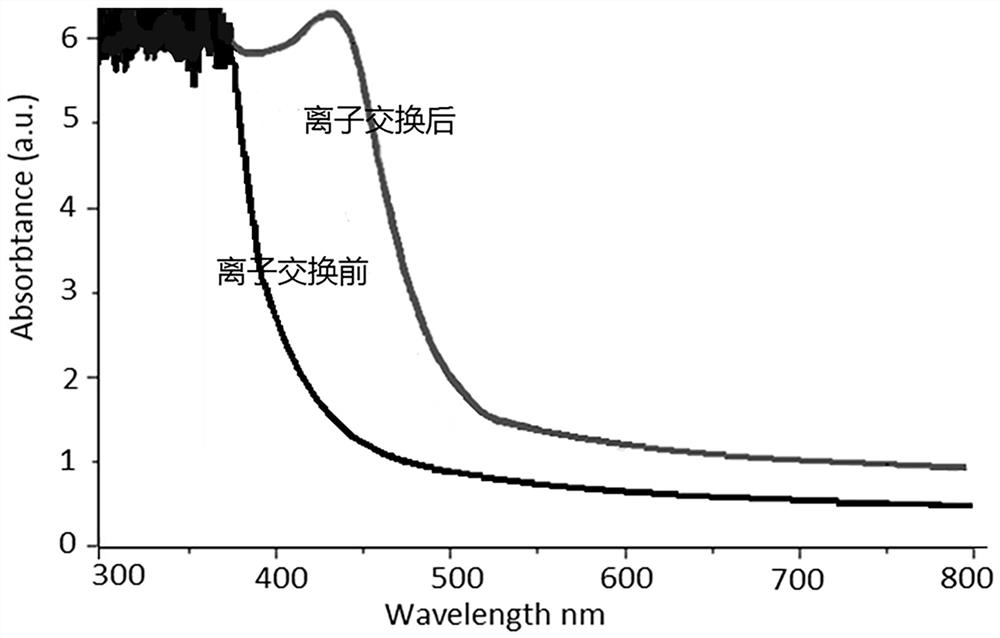

[0022] 1) Generate Fe 3 o 4 &Ag nano core shell material: 0.5gFeSO 4 .7H 2 O, 0.16g FeCl 3 .6H 2 O, and 0.1g PEG were mixed in 20mL of water and stirred continuously, and 10 mL of NaOH aqueous solution (10 mmol) was continuously added dropwise. Fe 3+ and Fe 2+ The molar ratio is controlled at 1.8:1, and 15 milliliters of Ag(NH 3 ) 2+ Aqueous solution (1 mg / mL) was directly added to the reaction solution at room temperature and kept stirring. After centrifugation (4000 rpm), a black to brown precipitate was slowly formed, and the excess reactant was repeatedly washed with water and acetone solution to obtain Fe 3 o 4 &Ag nano core-shell material. 2) Preparation of magneto-optical glass: PbO, Bi 2 o 3 , B 2 o 3 and Na 2 O oxide is used as the raw material to calculate, weigh and stir evenly according to the molar ratio of 45%, 45%, 8% and 2%, then add 100% Al 2 o 3 Melt in the crucible at 900 degrees Celsius for 1 hour, then quickly pour it onto a copper plat...

Embodiment 2

[0026] 1) Generate Fe 3 o 4 &Ag nano core shell material: 0.5gFeSO 4 .7H 2 O, 0.16g FeCl 3 .6H 2 O, and 0.1g PEG were mixed in 20mL of water and stirred continuously, and 10 mL of NaOH aqueous solution (10 mmol) was continuously added dropwise. Fe 3+ and Fe 2+ The molar ratio is controlled at 1.8:1, and 15 milliliters of Ag(NH 3 ) 2+ Aqueous solution (1 mg / mL) was directly added to the reaction solution at room temperature and kept stirring. After centrifugation (4000 rpm), a black to brown precipitate was slowly formed, and the excess reactant was repeatedly washed with water and acetone solution to obtain Fe 3 o 4 &Ag nano core-shell material. 2) Preparation of magneto-optical glass: PbO, Bi 2 o 3 , B 2 o 3 and Na 2 O oxide is used as the raw material to calculate, weigh and stir evenly according to the molar ratio of 45%, 45%, 8% and 2%, then add 100% Al 2 o 3 Melt in the crucible at 900 degrees Celsius for 1 hour, then quickly pour it onto a copper plat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com