Visible light responsive photocatalyst and preparation method thereof

A photocatalyst and visible light technology, which is applied in the field of photocatalysis, can solve the problems of high cost, poor stability of photosensitizer, and low photocatalytic efficiency, and achieve the effects of low cost, simple and easy preparation method, and good photocatalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

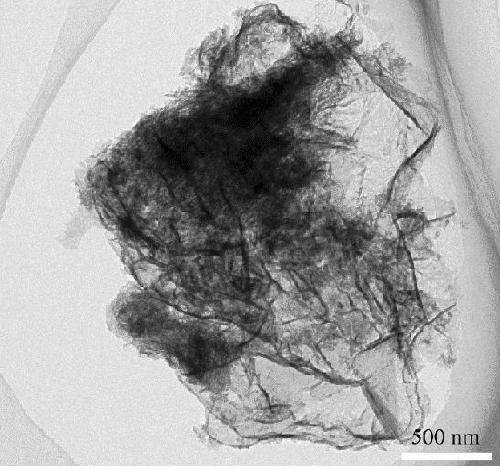

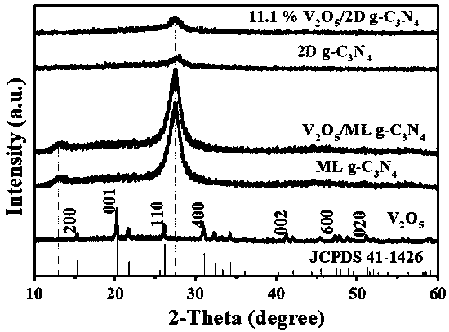

[0018] A visible light-responsive photocatalyst consisting of two-dimensional thin-layer V with a mass ratio of 1.71:100 2 o 5 and two-dimensional thin-layer g-C 3 N 4 Composite, the specific preparation method includes the following steps:

[0019] (1) First, the bulk V 2 o 5 Put it into a muffle furnace for calcination to 600°C, then quickly transfer it to liquid nitrogen, and rapidly cool it to obtain V 2 o 5 nanosheet, the V 2 o 5 Nanosheets were added to isopropanol, ultrasonicated for 30 min, stirred for 50 min to make it evenly mixed, and a suspension with a concentration of 0.01 mg / L was prepared;

[0020] (2) Add 1 mL of the suspension obtained in step (1) to melamine, stir for 40 min, and make it mix evenly;

[0021] (3) Move the evenly stirred mixture to a crucible, put it into a muffle furnace for secondary calcination, the heating rate of the first calcination is 2°C / min, keep it at 550°C for 240 min, and the heating rate of the second calcination is 10°C...

Embodiment 2

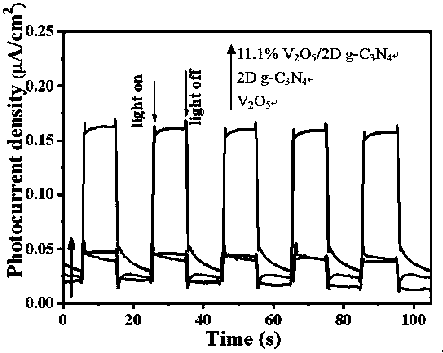

[0024] A visible-light-responsive photocatalyst consisting of two-dimensional thin-layer V with a mass ratio of 11.1:100 2 o 5 and two-dimensional thin-layer g-C 3 N 4 Composite, the specific preparation method includes the following steps:

[0025] (1) First, the bulk V 2 o 5 Put it into a muffle furnace for calcination to 800°C, then quickly transfer it to liquid nitrogen, and rapidly cool it to obtain V2 o 5 For nanosheets, add vanadium pentoxide nanosheets to isopropanol, sonicate for 30 minutes, and stir for 50 minutes to make it evenly mixed, and prepare a suspension with a concentration of 0.04 mg / L;

[0026] (2) Add 5 mL of the suspension obtained above into melamine, stir for 40 min, and make it evenly mixed;

[0027] (3) Move the evenly stirred mixture to a crucible, put it into a muffle furnace for secondary calcination, the heating rate of the primary calcination is 2 °C / min, keep it at 550 °C for 240 min, and the heating rate of the second calcination is 10 ...

Embodiment 3

[0030] A visible-light-responsive photocatalyst consisting of two-dimensional thin-layer V with a mass ratio of 35.4:100 2 o 5 and two-dimensional thin-layer g-C 3 N 4 Composite, the specific preparation method includes the following steps:

[0031] (1) First, the bulk V 2 o 5 Calcined to 600-900 ° C, then quickly transferred to liquid nitrogen, rapid cooling to obtain V 2 o 5 For nanosheets, add vanadium pentoxide nanosheets to isopropanol, sonicate for 30 minutes, and stir for 50 minutes to make it evenly mixed, and prepare a suspension with a concentration of 0.01 mg / L;

[0032] (2) Add 5 mL of the suspension obtained above into melamine, stir for 40 min, and make it mix evenly;

[0033] (3) Move the evenly stirred mixture to a crucible, put it into a muffle furnace for secondary calcination, the heating rate of the first calcination is 2°C / min, keep it at 550°C for 240 min, and the heating rate of the second calcination is 10°C / min min, kept at 530°C for 90 min, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com