Two-layer adhesive-free double-sided flexible copper-clad plate and preparation method thereof

A flexible copper clad laminate, double-sided technology, used in chemical instruments and methods, lamination, coating and other directions, can solve the problems of low heat resistance, low peel strength, large dimensional stability shrinkage of copper clad laminates, etc. Improve work efficiency, high peel strength and dimensional stability, reduce the effect of chemical reagents and labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

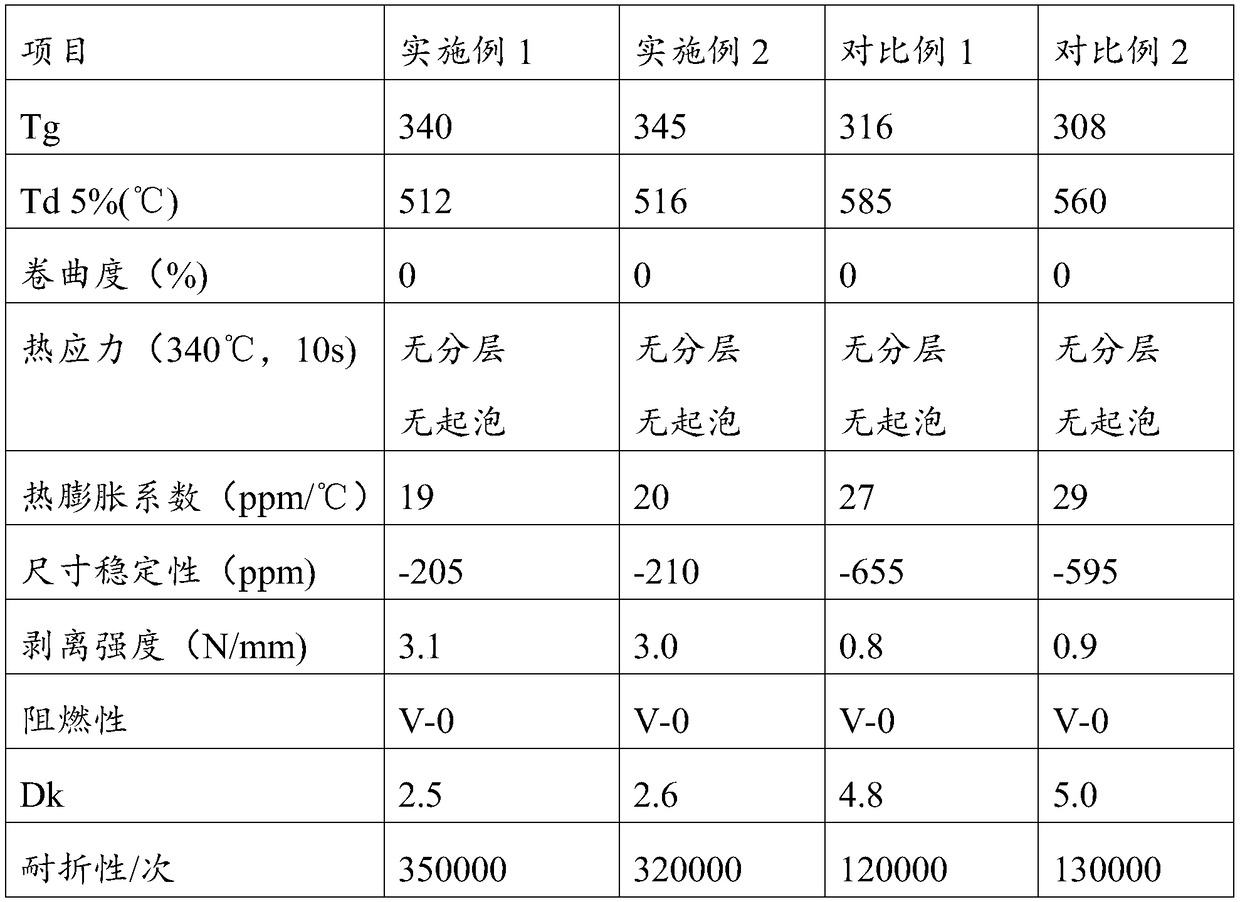

Examples

Embodiment 1

[0030] A two-layer adhesive-free double-sided flexible copper-clad laminate, including two upper and lower copper foil layers and an insulating layer sandwiched between the two copper foil layers, the insulating layer includes a polytetrafluoroethylene film in the middle and a polytetrafluoroethylene film positioned between polytetrafluoroethylene PBS / PLA film on the upper and lower sides of the vinyl fluoride film.

[0031] Wherein, the copper foil is a rolled copper foil with a thickness of 12-35 μm, a polytetrafluoroethylene film with a thickness of 20-35 μm, a PBS / PLA film with a thickness of 6-20 μm, and a weight ratio of PBS and PLA of 3 : 1, the number average molecular weight of PBS is 1-300,000, and the number-average molecular weight of PLA is 1-500,000.

[0032] The preparation method of the above-mentioned double-sided flexible copper clad laminate is as follows:

[0033] 1) Stir the PBS and PLA raw materials, heat and dry them, and transport them to the storage b...

Embodiment 2

[0038] A two-layer adhesive-free double-sided flexible copper-clad laminate, including two upper and lower copper foil layers and an insulating layer sandwiched between the two copper foil layers, the insulating layer includes a polytetrafluoroethylene film in the middle and a polytetrafluoroethylene film positioned between polytetrafluoroethylene PBS / PLA film on the upper and lower sides of the vinyl fluoride film.

[0039] Wherein, the copper foil is an electrolytic copper foil with a thickness of 12-70 μm, a polytetrafluoroethylene film with a thickness of 15-20 μm, a PBS / PLA film with a thickness of 6-20 μm, and a weight ratio of PBS and PLA of 5 1. The number average molecular weight of PBS is 300,000 to 500,000, and the number average molecular weight of PLA is 500,000 to 1,000,000.

[0040] The preparation method of the above-mentioned double-sided flexible copper clad laminate is as follows:

[0041] 1) Stir the PBS and PLA raw materials, heat and dry them, and transpor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com