A method for treating alcohol waste liquid discharged from molasses alcohol factory

A technology of alcohol waste liquid and molasses alcohol, which is applied in the chemical industry, can solve the problems of high cost, complex process of processing molasses alcohol waste liquid, and ineffective utilization of recyclables, so as to achieve the effect of energy saving, cost reduction and processing cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

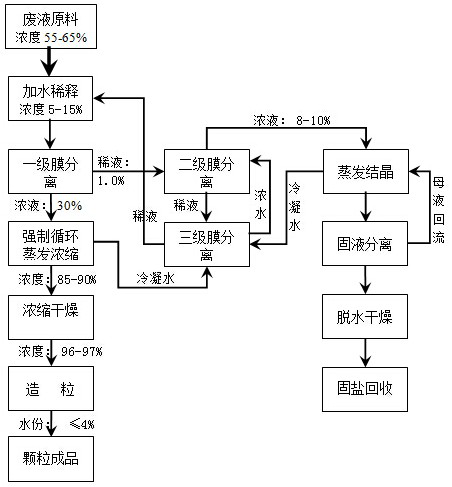

[0024] Such as figure 1 Shown, the invention provides a kind of method for processing the alcohol waste liquid that molasses alcohol factory discharges, comprises the steps:

[0025] 1) Dilute the alcohol waste liquid discharged from the molasses alcohol factory with water, and the concentration of the diluted alcohol waste liquid is 5-15%;

[0026] 2) The alcohol waste liquid diluted in step 1) is separated by a primary membrane device;

[0027] 3) The concentrated liquid separated by the primary membrane device is concentrated to a concentration of 85-90% by a forced circulation evaporator, and then concentrated and dried by a vacuum concentration dryer so that the concentration of the concentrated liquid is between 96 and 97%. The granulator makes solid granules with moisture ≤ 4%;

[0028] 4) The dilute liquid separated by the first-stage membrane device is separated by the second-stage membrane device, and the dilute liquid separated by the second-stage membrane device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com