Improved indoor environment-friendly coating

A technology for environmentally friendly coatings and raw materials, applied in the field of chemistry, can solve problems such as environmental pollution, and achieve the effects of obvious technological progress, enhanced strength, and reduced pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The invention provides an improved indoor environmental protection coating, which is prepared from the following raw materials in parts by weight:

[0038] Tailings powder 40~60;

[0039] Photocatalyst 0.2~1.5;

[0040] Filling 7~8;

[0041] Auxiliary 5~10;

[0042] Water 30-40.

[0043] Further, the additives include pigments, and the pigments include but not limited to titanium dioxide, iron red, chrome yellow and other inorganic pigments.

[0044] Further, the filler includes but not limited to any one of barite or calcium carbonate.

[0045] Further, the auxiliary agent includes any one or a combination of two or more of a leveling agent, a flocculant, a diluent, a drier, a plasticizer, a dispersant, and an anti-sedimentation agent.

[0046] Further, in the auxiliary agent, the number of parts by weight of the pigment is 2-4.

[0047] Further, in the above-mentioned auxiliary agent, the weight portion of the flattening agent is 1-2.

[0048] Further, in the a...

Embodiment 2

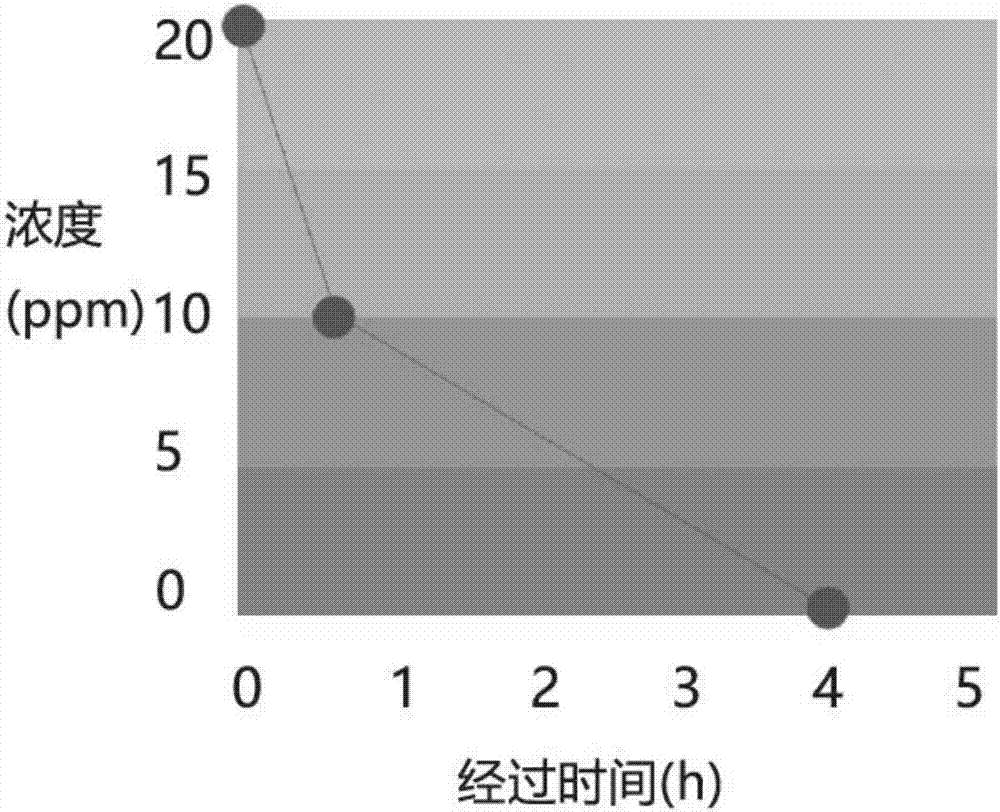

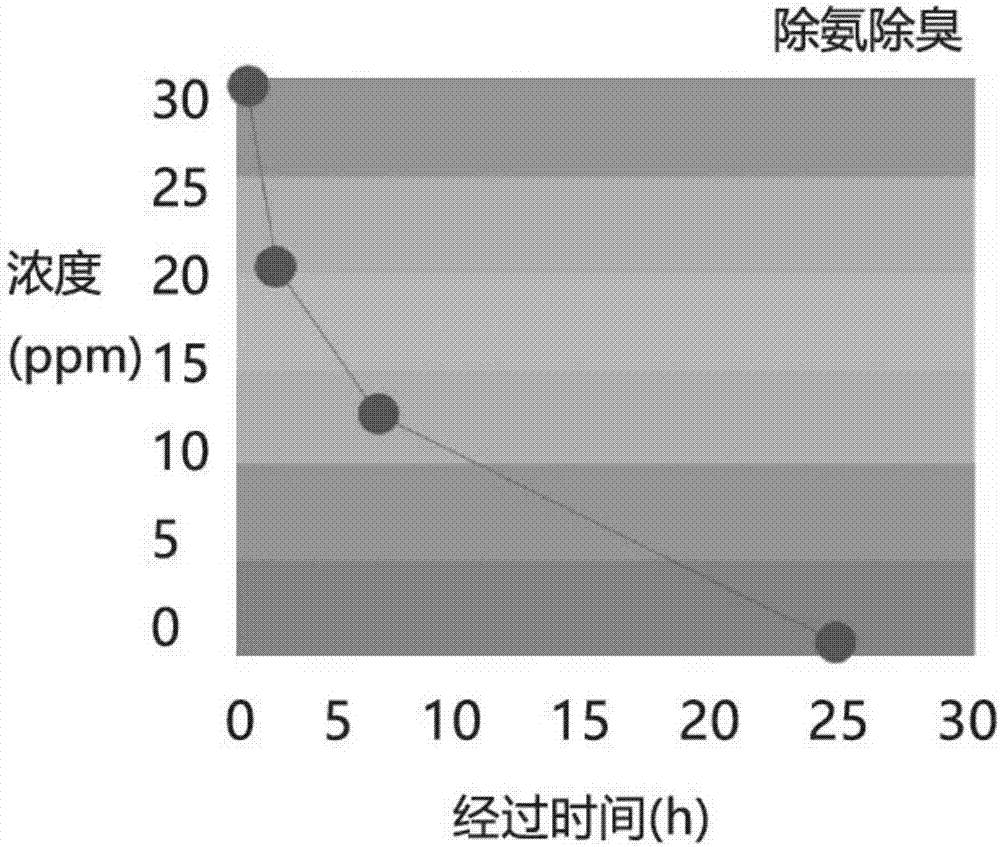

[0053] Such as figure 1 and figure 2 As shown, the improved indoor environmental protection paint of the present invention can decompose formaldehyde and ammonia.

[0054] Detection object: formaldehyde and ammonia;

[0055] Detection method: GasPark gas bag method B;

[0056] Detection light intensity: UV intensity 0.1mw / cm 2 .

Embodiment 3

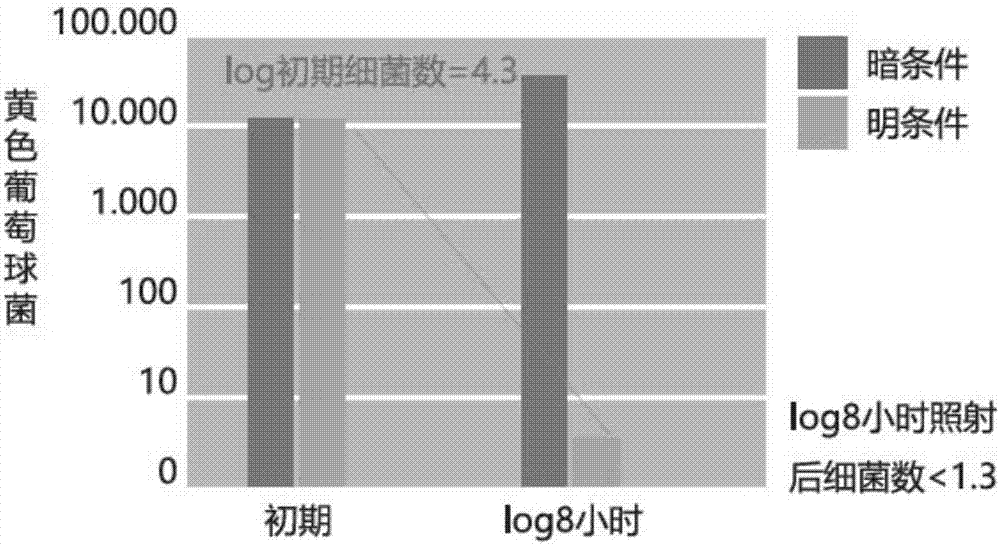

[0058] Such as image 3 and Figure 4 Shown, the improved indoor environmental protection coating of the present invention can kill Staphylococcus aureus, Klebsiella pneumoniae in the air.

[0059] Detection objects: Staphylococcus aureus, Klebsiella pneumoniae;

[0060] Detection method: JIS R 1702: 2121;

[0061] Detection light intensity: UV intensity 0.1mw / cm 2

[0062] Detection light time: 8 hours;

[0063] The preservation number of the bacteria used in the experiment: Staphylococcus aureus NBRC12732; Klebsiella pneumoniae NBRC13277.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com