Diesel engine vibration impact source identification method based on multi-measuring-point information fusion

An identification method, diesel engine technology, applied in measuring devices, internal combustion engine testing, measuring ultrasonic/sonic/infrasonic waves, etc., can solve the problems of low accuracy, low efficiency of identification methods, high diagnostic level requirements, etc., to achieve the effect of improving practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

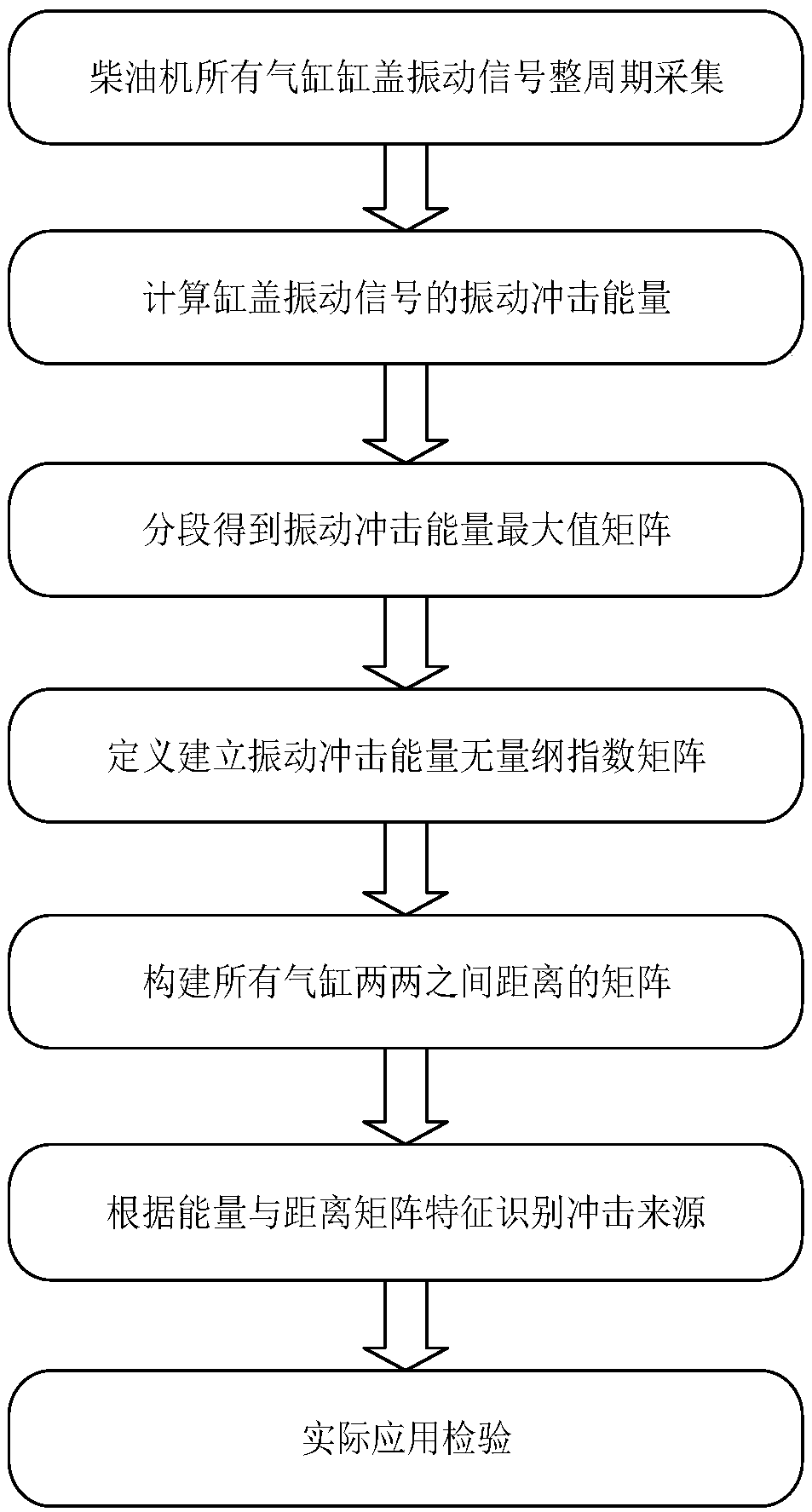

[0054] like figure 1 Shown, flow process of the present invention mainly comprises:

[0055] (1) The vibration signals of all cylinder heads of the diesel engine are collected throughout the cycle;

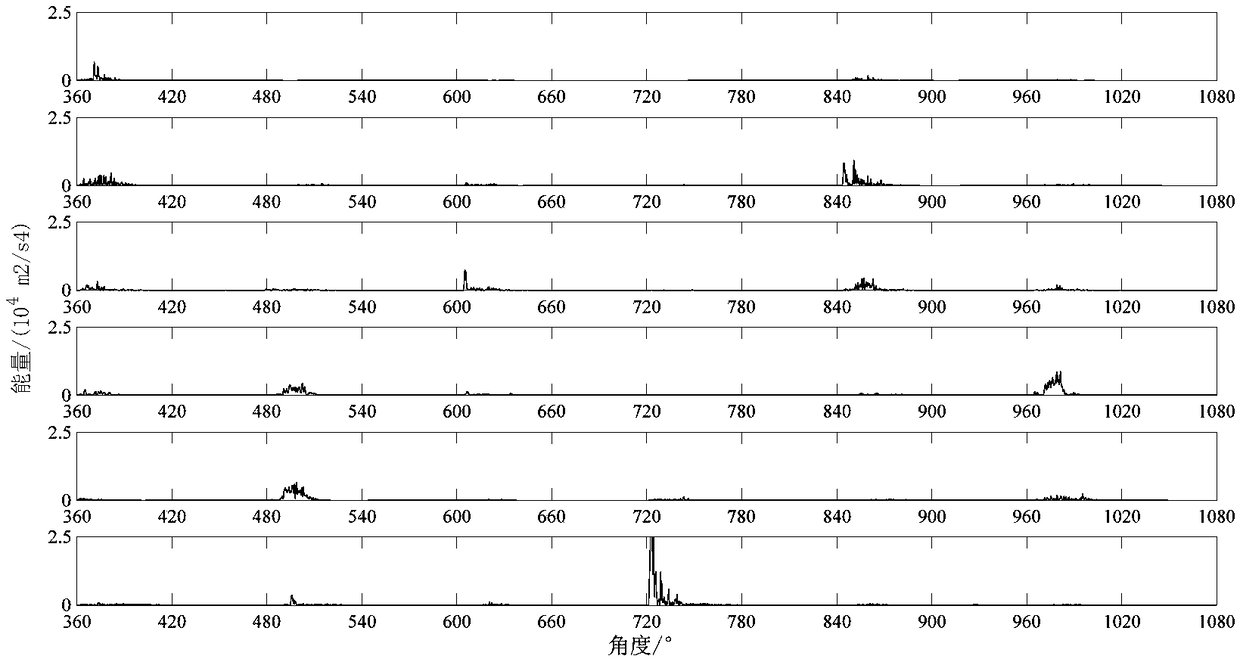

[0056] (2) Calculate the vibration impact energy of the cylinder head vibration signal;

[0057] (3) Obtain the maximum value matrix of vibration impact energy in sections;

[0058] (4) Define and establish the dimensionless index matrix of vibration impact energy;

[0059] (5) construct the matrix of the distance between all cylinders;

[0060] (6) Identify the source of the impact according to the characteristics of the energy and distance matrix;

[0061] (7) Practical application test.

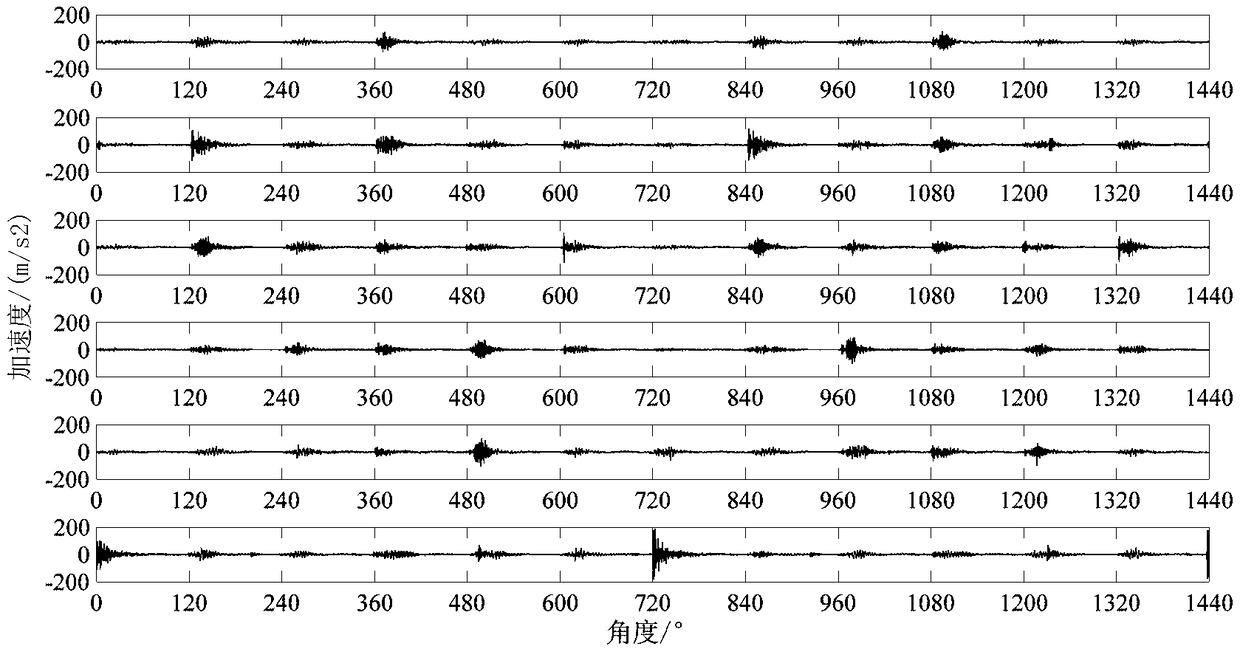

[0062] The present invention selects a 6-cylinder, 4-stroke Weichai WP10.270N diesel engine as the application object, and tests the actual use effect of the present invention.

[0063] 1. Case 1 identifies the source of vibration and shock in the signal under the normal state of the app...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com