Servo motor control method and device

A technology of servo motor and control method, applied in adaptive control, general control system, control/regulation system, etc., can solve the problems of reduced robustness and stability, no suppression of external strong interference, and impact on system control performance. , to improve the robustness and stability, shorten the adjustment time, and improve the control performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

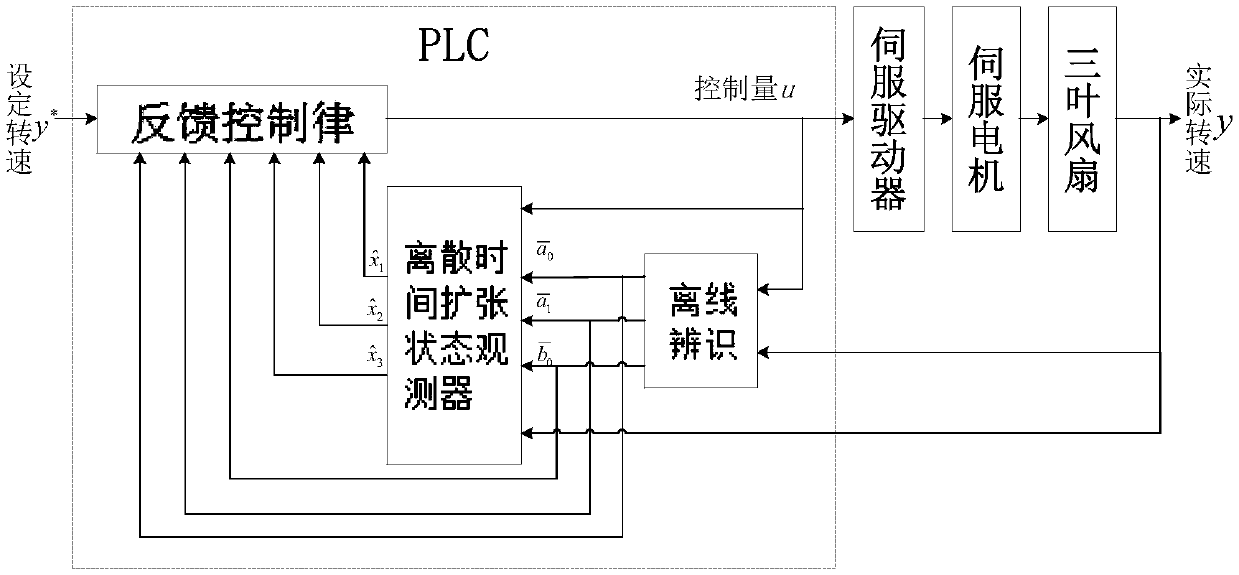

[0048] The embodiment of the present invention provides a servo motor control method, which can be applied to a servo drive system. As a high-end product of transmission technology in the field of motion control, the servo drive system has powerful functions, small size and outstanding control effect, and is widely used in industrial production. middle. However, due to the limitations of most control methods, they do not have the ability to suppress strong external disturbances. The servo drive system in the embodiment of the present invention is such as figure 1 As shown, the whole system includes: servo controller, servo motor and three-bladed fan driven by the servo motor.

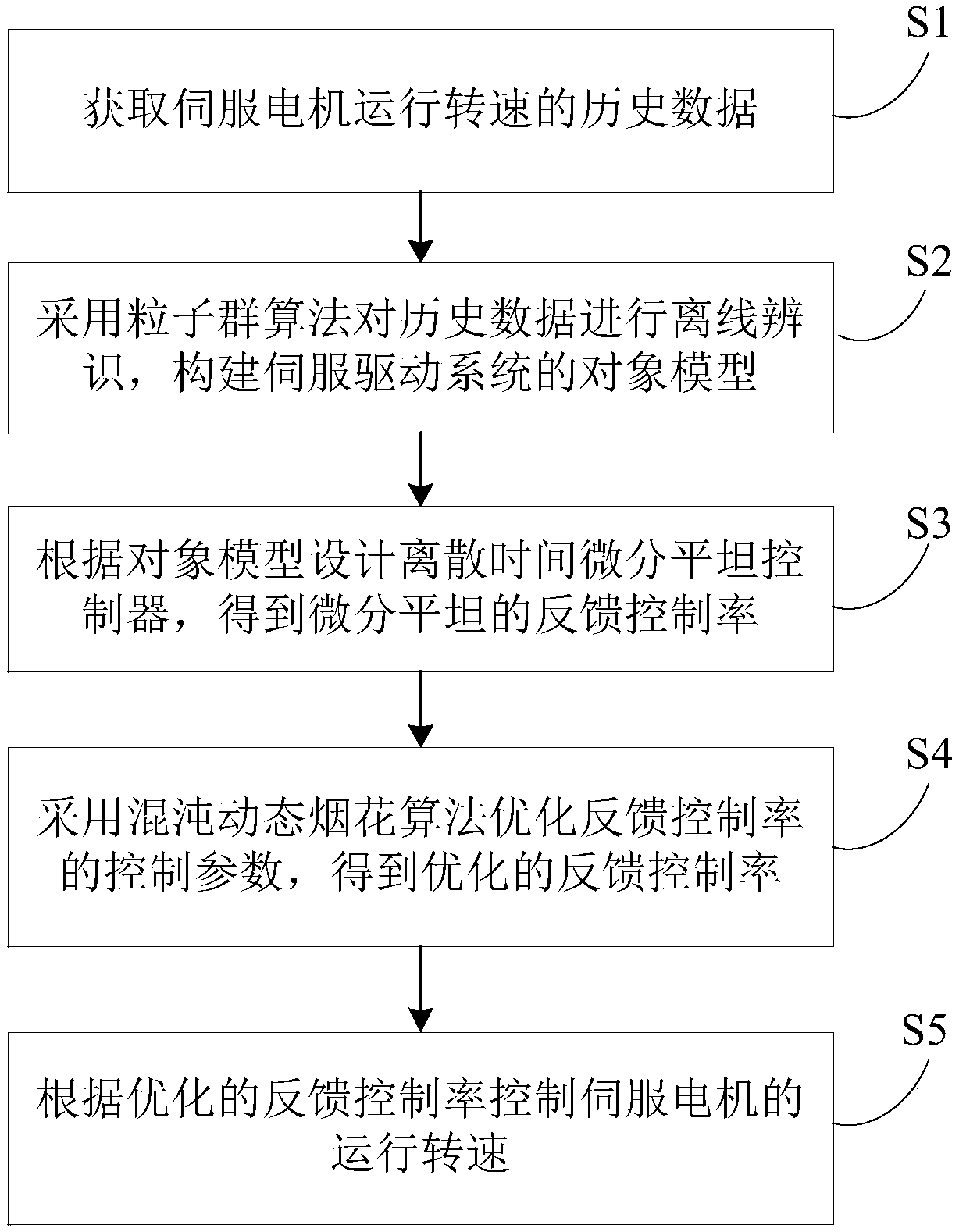

[0049] Such as figure 2 As shown, the method includes the following steps:

[0050] Step S1: Obtain the historical data of the running speed of the servo motor.

[0051] In the embodiment of the present invention, PLC equipment is used to realize the above servo motor control method, such as figur...

Embodiment 2

[0102] An embodiment of the present invention provides a servo motor control device, such as Figure 8 As shown, the servo motor control device includes: a historical data acquisition module 1, configured to acquire historical data of the operating speed of the servo motor in the servo drive system. For details, refer to step S1 in Embodiment 1.

[0103] The object model building module 2 is used for offline identification of historical data by using particle swarm optimization algorithm, and constructing the object model of the servo drive system. For details, refer to step S2 in Embodiment 1.

[0104] The feedback control law building block 3 is used to design a discrete-time differential flat controller according to the object model to obtain a differential flat feedback control law. For details, refer to step S3 in Embodiment 1.

[0105] The feedback control law optimization module 4 is used to optimize the control parameters of the feedback control law by using the cha...

Embodiment 3

[0108] An embodiment of the present invention provides a non-transitory computer storage medium, the computer storage medium stores computer-executable instructions, and the computer-executable instructions can execute the servo motor control method in any of the first embodiments above. Wherein, the above-mentioned storage medium may be a magnetic disk, an optical disk, a read-only memory (Read-Only Memory, ROM), a random access memory (Random Access Memory, RAM), a flash memory (Flash Memory), a hard disk (Hard Disk Drive, abbreviation: HDD) or a solid-state drive (Solid-State Drive, SSD), etc.; the storage medium may also include a combination of the above types of memories.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com