Corn straw fermented feed for fattening pigs

A technology for corn stalks and pig feed, which is applied in animal feed and other directions, can solve the problems of shortage of protein feed resources and insufficient supply, and achieve the effects of saving grain feed raw materials, relieving supply pressure and improving utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

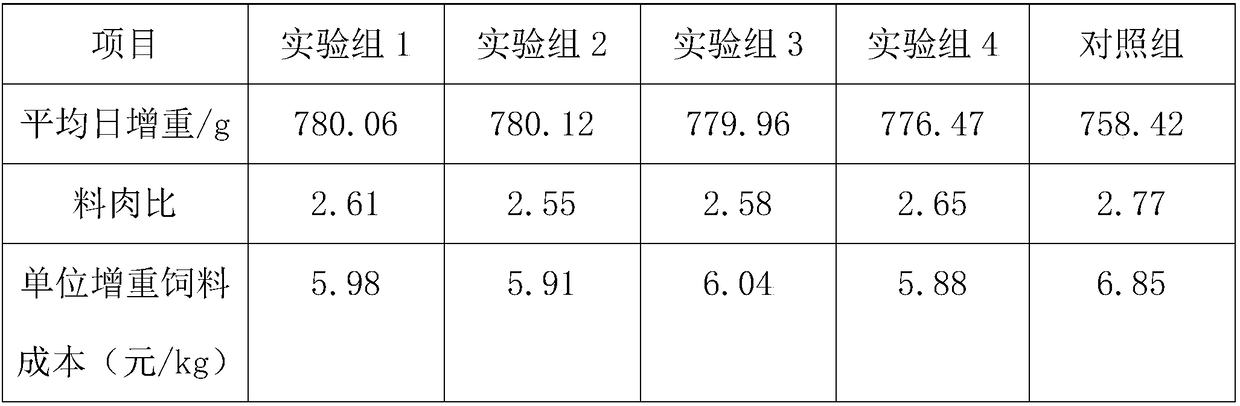

Examples

Embodiment 1

[0017] A feed for fattening pigs fermented with corn stalks, comprising the following components by weight: 30 parts of white lentil grass powder, 100 parts of fermented material, 35 parts of rice bran, 50 parts of subflour, 25 parts of bran, 25 parts of puffed corn, puffed soybean 5 parts, 30 parts of wheat, 15 parts of peeled soybean meal, 6 parts of fish meal, 1 part of stone powder, 2 parts of calcium hydrogen phosphate, 0.2 part of multivitamin, 0.6 part of compound trace element;

[0018] The preparation of the fermented material: mix the raw material corn stalks, grape pomace, rice bran, soybean meal, etc. according to the mass ratio of 25:10:15:18, add water according to the material-to-water ratio of 1:0.3, steam sterilize, after cooling, add compound Enzyme, at a temperature of 55°C, enzymatically hydrolyze for 2 days, inoculate complex bacteria, ferment at a temperature of 30°C for 5 days, and obtain a fermented material after drying; the complex enzyme is composed o...

Embodiment 2

[0020] A feed for fattening pigs fermented with corn stalks, characterized in that it comprises the following components in parts by weight: 50 parts of white lentil grass powder, 80 parts of fermented material, 45 parts of rice bran, 35 parts of subflour, 40 parts of bran, and 15 parts of puffed corn 8 parts of puffed soybean, 15 parts of wheat, 30 parts of peeled soybean meal, 2 parts of fish meal, 3 parts of stone powder, 0.5 part of calcium hydrogen phosphate, 1 part of multivitamin, 0.2 part of compound trace element;

[0021] The preparation of the fermented material: mix the raw material corn stalks, grape pomace, rice bran, soybean meal, etc. according to the mass ratio of 45:4:25:10, add water according to the material-to-water ratio of 1:1.2, steam sterilize, after cooling, add compound Enzyme, at a temperature of 45°C, enzymolysis for 5 days, inoculating complex bacteria, fermenting at a temperature of 25°C for 10 days, and drying to obtain a fermented material; the ...

Embodiment 3

[0023] A feed for fattening pigs fermented with corn stalks, comprising the following components by weight: 35 parts of white lentil grass powder, 95 parts of fermented material, 37 parts of rice bran, 45 parts of subflour, 30 parts of bran, 22 parts of puffed corn, puffed soybean 6 parts, 25 parts of wheat, 18 parts of peeled soybean meal, 5 parts of fish meal, 1 part of stone powder, 1.7 parts of calcium hydrogen phosphate, 0.4 parts of multivitamins, 0.5 parts of compound trace elements;

[0024] The preparation of the fermented material: mix the raw material corn stalks, grape pomace, rice bran, soybean meal, etc. according to the mass ratio of 25:10:15:18, add water according to the material-to-water ratio of 1:0.3, steam sterilize, after cooling, add compound Enzyme, at a temperature of 55°C, enzymatically hydrolyze for 2 days, inoculate complex bacteria, ferment at a temperature of 30°C for 5 days, and obtain a fermented material after drying; the complex enzyme is compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com