Paste composition for removing formaldehyde and preparation method thereof

The technology of a paste composition and a preparation method, which is applied in the field of daily necessities, can solve problems such as limited adsorption capacity, and achieve the effects of simple and controllable operation and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

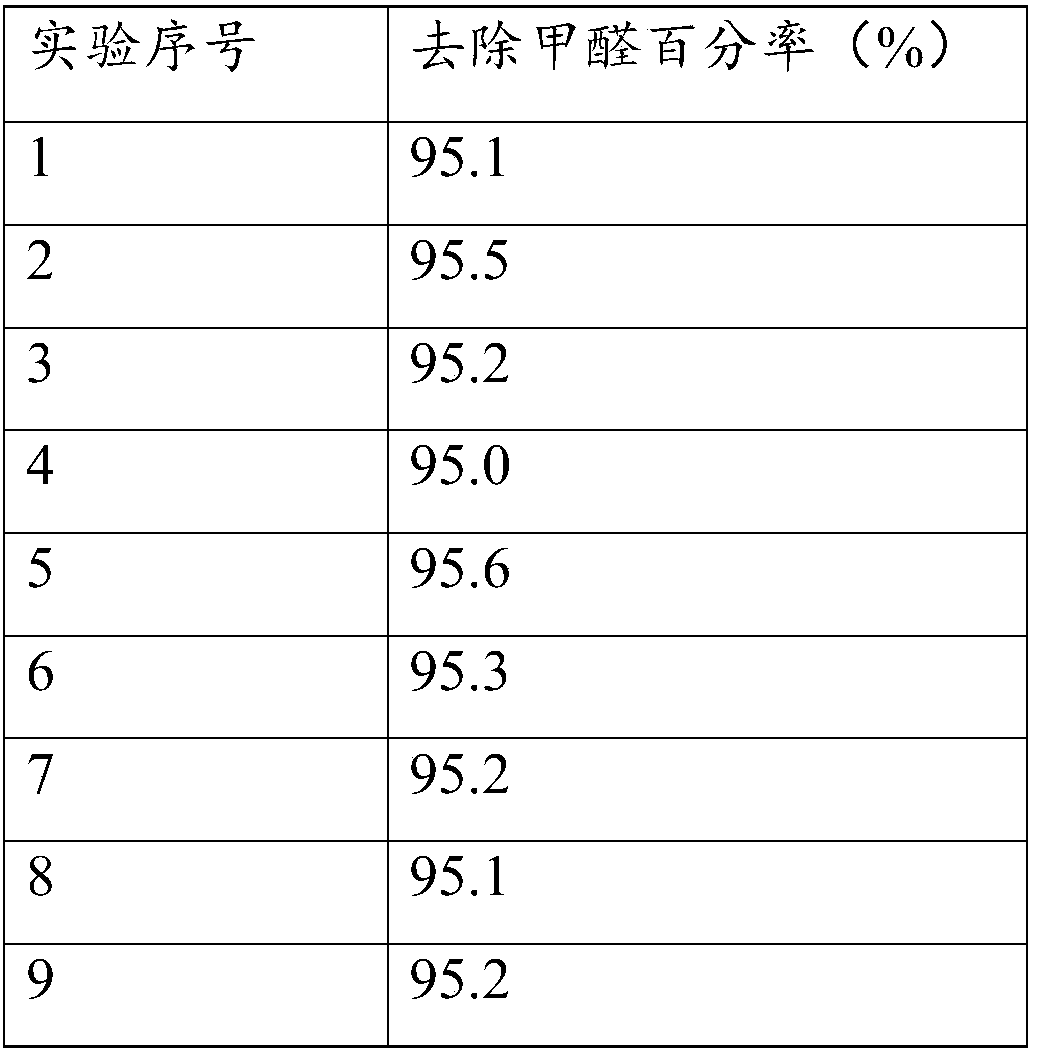

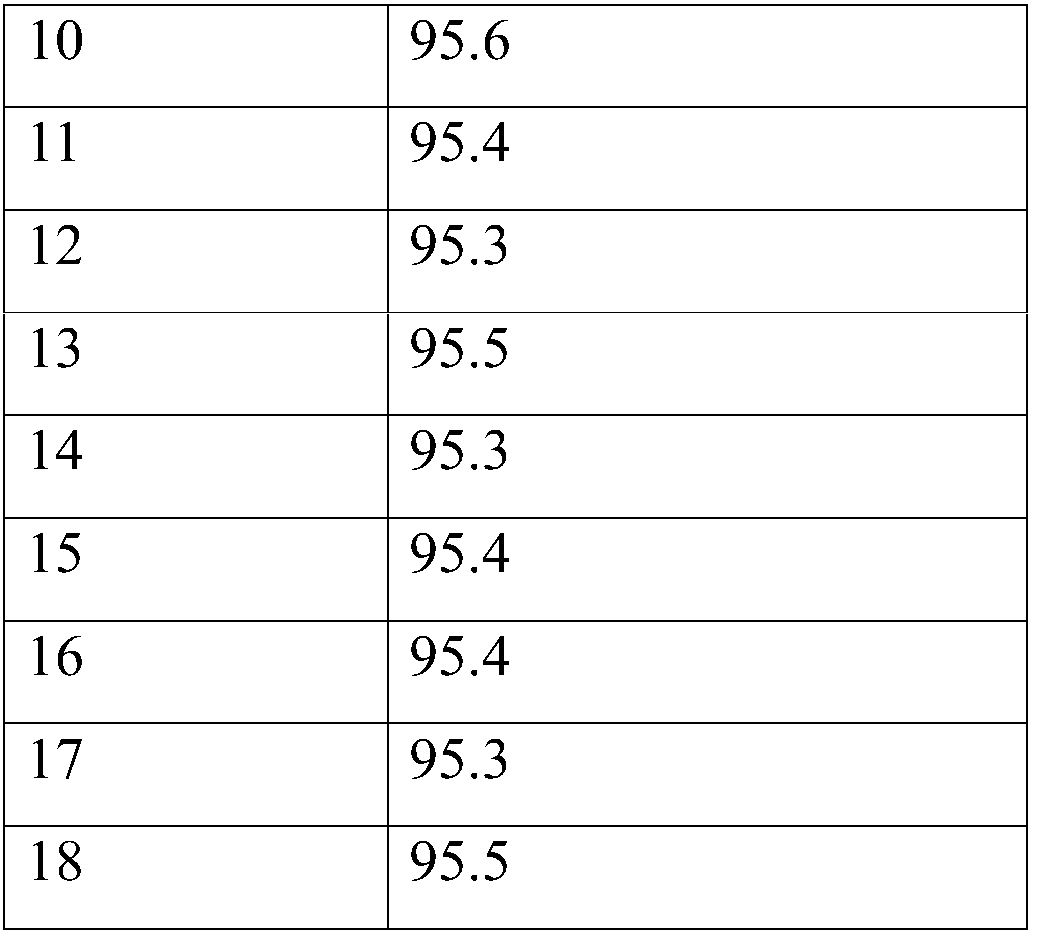

Examples

Embodiment 1

[0052] A paste-like composition for removing formaldehyde, which includes a paste-like substrate and carbon powder, and the carbon powder is dispersed on the surface of the substrate in contact with the air. The pasty composition for removing formaldehyde is made by the following method:

[0053] S1. Configure raw materials.

[0054] In terms of mass percentage, the raw materials of the paste composition include:

[0055] Formaldehyde removal component 8.1%, oil phase component 30.1%, water phase additive 4.01%, sodium oxide 0.4%, auxiliary component 2.0%, and water balance.

[0056] Wherein, the formaldehyde-removing component is calculated by mass percent of the paste composition, including:

[0057] Titanium Dioxide 0.7%, Diatomaceous Earth 4.7%, Cactus Stem Extract 1.1%, Dragon Head Bamboo Extract 1.1%, and Charcoal Powder 0.5%.

[0058] The formaldehyde removal component is based on the mass percentage of the paste composition, including: 14.6% stearic acid, 3% ozokeri...

Embodiment 2

[0063] A paste-like composition for removing formaldehyde, which includes a paste-like substrate and carbon powder, and the carbon powder is dispersed on the surface of the substrate in contact with the air. The pasty composition for removing formaldehyde is made by the following method:

[0064] S1. Configure raw materials.

[0065] In terms of mass percentage, the raw materials of the paste composition include:

[0066] Formaldehyde removal component 21.6%, oil phase component 20.1%, water phase additive 8.055%, sodium oxide 0.25%, auxiliary component 2.0%, and water balance.

[0067] Wherein, the formaldehyde-removing component is calculated by mass percent of the paste composition, including:

[0068] Titanium Dioxide 1.85%, Diatomaceous Earth 10.8%, Cactus Stem Extract 3.1%, Dragon Head Bamboo Extract 3.1%, and Charcoal Powder 2.75%.

[0069] The formaldehyde removal component is based on the mass percentage of the paste composition, including: stearic acid 8.85%, ozok...

Embodiment 3

[0074] A paste-like composition for removing formaldehyde, which includes a paste-like substrate and carbon powder, and the carbon powder is dispersed on the surface of the substrate in contact with the air. The pasty composition for removing formaldehyde is made by the following method:

[0075] S1. Configure raw materials.

[0076] In terms of mass percentage, the raw materials of the paste composition include:

[0077] Formaldehyde removal component 35.1%, oil phase component 10.1%, water phase additive 12.1%, sodium oxide 0.1%, auxiliary component 2.0%, and water balance.

[0078] Wherein, the formaldehyde-removing component is calculated by mass percent of the paste composition, including:

[0079] Titanium dioxide 3.0%, diatomaceous earth 16.9%, cactus stem extract 5.1%, dragon head bamboo extract 5.1%, and charcoal powder 5.0%.

[0080] The formaldehyde removal component is based on the mass percentage of the paste composition, including: 3.1% stearic acid, 1.0% ozok...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com