A new type of inorganic heat insulation flame retardant material and its preparation method

A technology of heat insulation and flame retardant materials, which is applied in the field of heat insulation and flame retardant materials, can solve the problems of low heat resistance temperature, high cost, and long cycle, and achieve the effect of good compression resistance and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

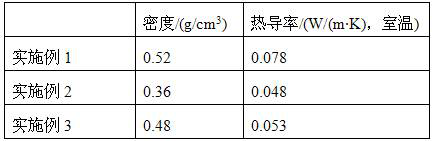

Examples

Embodiment 1

[0021] A new type of inorganic thermal insulation and flame retardant material is made of the following raw materials in parts by weight:

[0022] 18 parts of unsaturated resin, 0.09 parts of initiator, 2 parts of coupling agent, 30 parts of fiber material, 100 parts of hollow glass microspheres;

[0023] Wherein, the unsaturated resin is unsaturated polyester resin 191#; the initiator is a mixture of methyl ethyl ketone peroxide and cobalt naphthenate, and 0.05 part of methyl ethyl ketone peroxide and 0.04 part of cobalt naphthenate; Coupling agent is KH-560; Described fiber material is glass fiber; Described hollow glass microsphere is K20 product of 3M Company, and its density is 0.20 g / cm 3 .

[0024] Preparation method, the steps are as follows:

[0025] (1) Stir and mix the unsaturated resin, initiator, coupling agent, fiber material, and hollow glass microspheres evenly in a sealable metal container according to the weight parts to obtain a slurry;

[0026] (2) After...

Embodiment 2

[0029] A new type of inorganic thermal insulation and flame retardant material is made of the following raw materials in parts by weight:

[0030] 20 parts of unsaturated resin, 0.03 parts of initiator, 3 parts of coupling agent, 25 parts of fiber material, 100 parts of hollow glass microspheres;

[0031] Wherein, the unsaturated resin is vinyl resin VER-2; the initiator is BPO; the coupling agent is KH-560; the fiber material is basalt fiber; the hollow glass microsphere is 3M company XLD3000 product whose density is 0.23g / cm 3 .

[0032] Preparation method, the steps are as follows:

[0033] (1) Stir and mix the unsaturated resin, initiator, coupling agent, fiber material, and hollow glass microspheres evenly in a sealable metal container according to the weight parts to obtain a slurry;

[0034] (2) After sealing the sealable metal container, place it in a drying oven, and cure it according to the curing process of first holding at 20 ℃ for 3 hours, and then at 40 ℃ for ...

Embodiment 3

[0037] A new type of inorganic thermal insulation and flame retardant material is made of the following raw materials in parts by weight:

[0038] 15 parts of unsaturated resin, 0.04 part of initiator, 1 part of coupling agent, 20 parts of fiber material, 100 parts of hollow glass microspheres;

[0039] Wherein, the unsaturated resin is a mixture of unsaturated polyester resin 191# and vinyl ester resin MFE-2, and 10 parts of unsaturated polyester resin 191#, 5 parts of vinyl ester resin MFE-2; Described initiator is AIBN; Described coupling agent is KH-560; Described fiber material is carbon fiber; Described hollow glass microsphere is 3M Company VS5500 product, and its density is 0.38 g / cm 3 .

[0040] Preparation method, the steps are as follows:

[0041] (1) Stir and mix the unsaturated resin, initiator, coupling agent, fiber material, and hollow glass microspheres evenly in a sealable metal container according to the weight parts to obtain a slurry;

[0042] (2) After ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com