Large-scale honeycomb ceramic assembly and preparation method thereof

A honeycomb ceramic body and technology of honeycomb ceramics, applied in ceramic products, other household appliances, applications, etc., can solve the problems of mold hole wall deformation, incomplete molding, and honeycomb hole blockage, so as to achieve low equipment requirements and improve assembly efficiency , high-strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

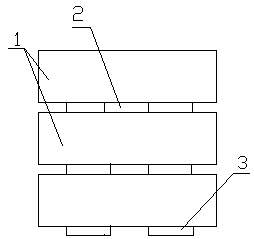

[0023] Embodiment 1: as figure 1 and figure 2 As shown, according to the following method steps, the traditional small honeycomb ceramic bodies 1 with different heights and the same shape are superimposed and combined into a regular large honeycomb ceramic body with a pressure-reducing channel: the traditional small honeycomb ceramic body has a boss 3, and the traditional small honeycomb ceramic body The honeycomb ceramic bodies 1 are superimposed on each other to form a pressure-reducing channel A2

[0024] a. Prepare the traditional small honeycomb ceramic body 1 with different heights and the same shape by integral extrusion molding;

[0025] b. Preparation of adhesive: Prepare adhesive A according to the ratio of silica sol: alumina powder = 1:5, which is used for combination bonding of small honeycomb ceramic body 1; according to the ratio of silica sol: alumina powder = 5:1 Prepare binder B for bonding between the combined honeycomb body and inorganic fiber cotton (gl...

Embodiment 2

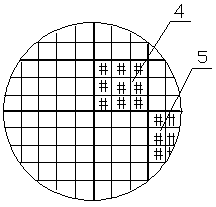

[0027] Embodiment 2: according to the following method steps, as image 3 As shown, the regular small honeycomb ceramic body 4 and the special-shaped small honeycomb ceramic body 5 with different heights and the same shape are combined into a regular large honeycomb ceramic body with a pressure-reducing channel:

[0028] a. Prepare the small honeycomb ceramic body 4 and the special-shaped small honeycomb ceramic body 5 made by integral extrusion molding;

[0029] b. Preparation of adhesive: prepare adhesive A according to the ratio of alumina sol: alumina powder = 1:3, which is used for combined bonding of small honeycomb ceramic bodies; prepare according to the ratio of silica sol: alumina powder = 3:1 Adhesive B, used for bonding between the combined honeycomb body and glass fiber wool;

[0030] c. Apply adhesive A evenly and evenly on the outer wall surface of the traditional small honeycomb ceramics that needs to be bonded. The coating amount of adhesive A per square mete...

Embodiment 3

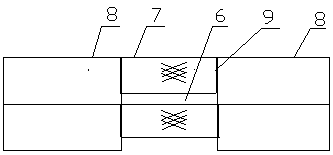

[0031] Embodiment 3: according to the following method steps, as Figure 4 As shown, the small honeycomb ceramic body I7 for combination and the small honeycomb ceramic body II8 for combination with different heights and shapes are combined into a special-shaped large honeycomb ceramic body with a pressure-reducing channel B6:

[0032] a. Prepare small honeycomb ceramic bodies Ⅰ7 and Ⅱ8 for assembly with different heights and shapes made by integral extrusion;

[0033] b. Preparation of adhesive: Prepare adhesive A according to the ratio of aluminum phosphate glue: ceramic blank tire powder = 1:3, which is used for combined bonding of small honeycomb ceramic bodies; according to aluminum phosphate glue: ceramic blank tire powder = 3: The ratio of 1 is used to prepare binder B, which is used for bonding between the combined honeycomb body and inorganic fiber cotton 10 (ceramic);

[0034] c. Apply adhesive A evenly and evenly on the outer wall surface of the small honeycomb cer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com