Flexible piezoelectric composite film and preparation method thereof

A composite film, flexible piezoelectric technology, applied in the direction of coating, etc., to achieve uniform and stable stretching, uniform force, and reduce the chance of damage and wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

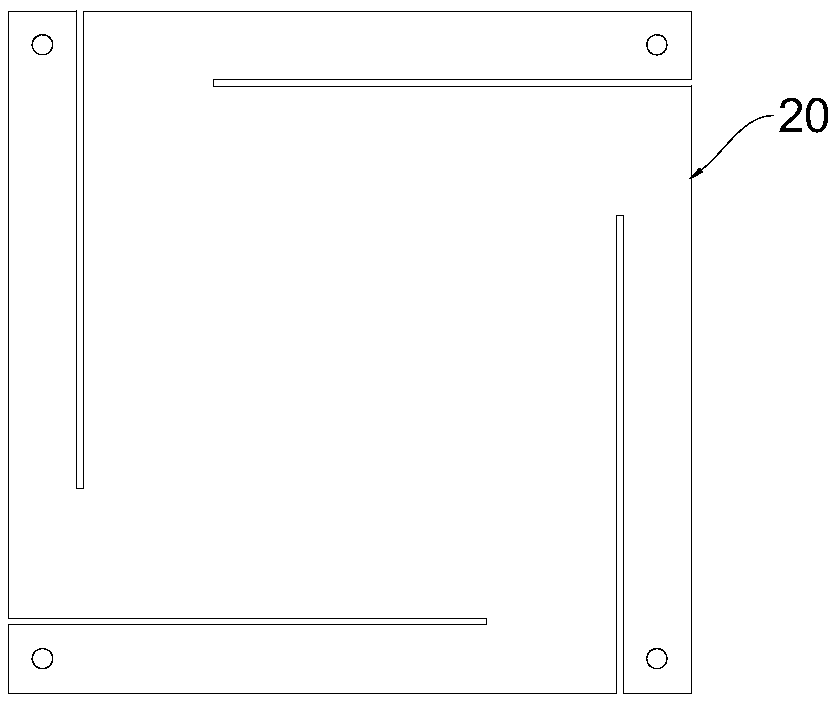

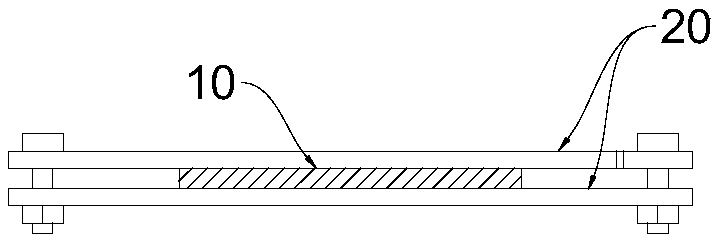

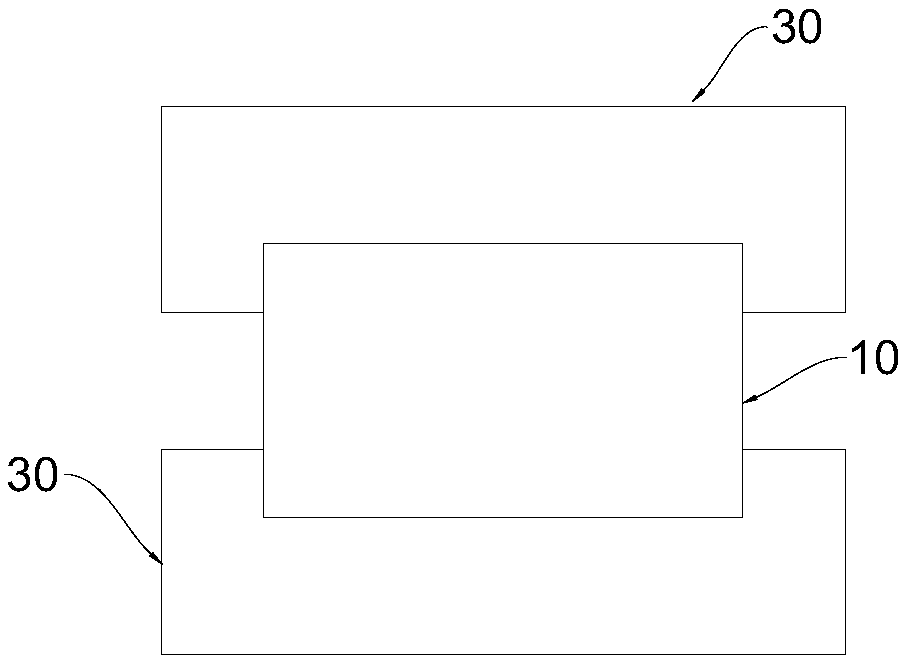

Method used

Image

Examples

Embodiment 1

[0039] The preparation method of the flexible piezoelectric composite film of this embodiment includes:

[0040] (1) Nano-SiO 2 The particles were dissolved in DMF solvent and dispersed ultrasonically, then added PVDF powder and mechanically stirred evenly to obtain SiO 2 / PVDF mixed solution; wherein, the mass ratio of PVDF powder to DMF solvent is 1:5, nano-SiO 2 Particles account for 1% of the mass of PVDF powder;

[0041] Preferably, the power of ultrasonic dispersion is 700W, and the time of ultrasonic dispersion is 40min; the stirring speed of mechanical stirring is 1800rpm, and the stirring time is 40min.

[0042] (2) SiO obtained in step (1) 2 The / PVDF mixed solution is subjected to defoaming treatment, then poured into a mold and placed in a ventilated environment on a constant temperature platform at 75°C for 3 hours to obtain the first composite film;

[0043] (3) The first composite film is taken out from the mold and subjected to hot-pressing treatment. The h...

Embodiment 2

[0052] The preparation method of the flexible piezoelectric composite film of this embodiment includes:

[0053] (1) Nano-SiO 2 The particles were dissolved in DMF solvent and dispersed ultrasonically, then added PVDF powder and mechanically stirred evenly to obtain SiO 2 / PVDF mixed solution; wherein, the mass ratio of PVDF powder to DMF solvent is 1:8, nano-SiO 2 The particles account for 10% of the PVDF powder mass;

[0054] Preferably, the power of ultrasonic dispersion is 800W, and the time of ultrasonic dispersion is 20min; the stirring speed of mechanical stirring is 2200rpm, and the stirring time is 20min.

[0055] (2) SiO obtained in step (1) 2 The / PVDF mixed solution is subjected to defoaming treatment, then poured into a mold and placed in a ventilated environment on a constant temperature platform at 85°C for 2 hours to obtain the first composite film;

[0056] (3) The first composite film is taken out from the mold and subjected to hot-pressing treatment. The...

Embodiment 3

[0065] The preparation method of the flexible piezoelectric composite film of this embodiment includes:

[0066] (1) Nano-SiO 2 The particles were dissolved in DMF solvent and dispersed ultrasonically, then added PVDF powder and mechanically stirred evenly to obtain SiO 2 / PVDF mixed solution; wherein, the mass ratio of PVDF powder to DMF solvent is 1:6, nano-SiO 2 The particles account for 5% of the PVDF powder mass;

[0067] Preferably, the power of ultrasonic dispersion is 750W, and the time of ultrasonic dispersion is 30min; the stirring speed of mechanical stirring is 2000rpm, and the stirring time is 30min.

[0068] (2) SiO obtained in step (1) 2 / PVDF mixed solution is subjected to defoaming treatment, then poured into a mold and placed in a ventilated environment on a constant temperature platform at 80°C for 2.5 hours to obtain the first composite film;

[0069] (3) The first composite film is taken out from the mold and subjected to hot-pressing treatment. The ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com