Wood-color-like 3D printing wire material based on illegal cooking oil, and preparation and printing methods of wire material

A 3D printing and gutter oil technology, applied in the direction of additive processing, etc., can solve the problems of low toughness and high cost, and achieve the effects of good toughness, reduced production cost, good market prospects and social value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

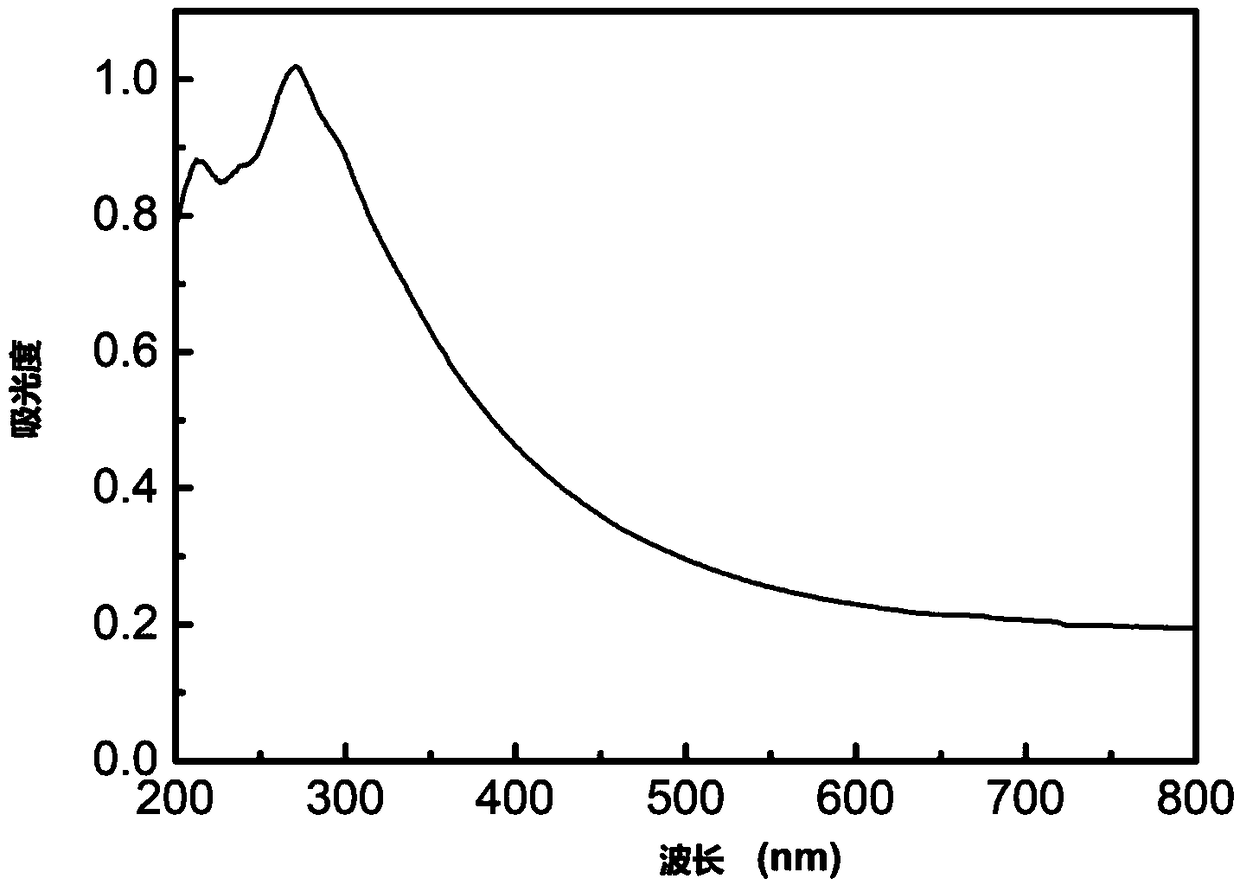

[0035] 1. Collect 100g of gutter oil obtained from the simple processing of swill from fast food restaurants. Get 62g of hydrogen peroxide (30% hydrogen peroxide aqueous solution), 16g of glacial acetic acid, 0.4g of concentrated sulfuric acid, and 0.4g of urea, mix them, and react in the dark at 40°C for 12 hours in the dark to obtain an epoxidation reagent. Then, in a glass reactor with a stirrer, add the obtained waste oil, heat to 40°C, slowly add the epoxidation reagent dropwise under stirring, after the dropwise addition, raise the temperature to 70°C, heat and stir for 3 hours, then cool and stand , separate the oil layer, wash 3 times with 5% sodium bicarbonate solution, then wash 6 times with 60°C deionized water, collect the oil layer, and vacuum rotary evaporation at 70°C for 1 hour until it becomes clear and anhydrous A pale yellow, liquid epoxy gutter oil product is obtained.

[0036] 2. Weigh 50g of epoxy waste oil and 0.05g of hydroquinone obtained in the previ...

Embodiment 2

[0040] 1. Collect 100g of gutter oil obtained from the simple processing of swill from fast food restaurants. Get 93g of hydrogen peroxide (30% hydrogen peroxide aqueous solution), 16g of glacial acetic acid, 0.4g of concentrated sulfuric acid, and 0.4g of urea, mix them, and react in the dark at 40°C for 12 hours in the dark to obtain an epoxidation reagent. Then, in a glass reactor with a stirrer, add the obtained waste oil, heat to 40°C, slowly add the epoxidation reagent dropwise under stirring, after the dropwise addition, raise the temperature to 70°C, heat and stir for 3 hours, then cool and stand , separate the oil layer, wash 3 times with 5% sodium bicarbonate solution, then wash 6 times with 60°C deionized water, collect the oil layer, and vacuum rotary evaporation at 70°C for 1 hour until it becomes clear and anhydrous A pale yellow, liquid epoxy gutter oil product is obtained.

[0041] 2. Weigh 50g of epoxy waste oil and 0.05g of hydroquinone obtained in the previ...

Embodiment 3

[0045] 1. Collect 100g of gutter oil obtained from the simple processing of swill from fast food restaurants. Get 155g of hydrogen peroxide (30% hydrogen peroxide aqueous solution), 16g of glacial acetic acid, 0.4g of concentrated sulfuric acid, and 0.4g of urea, mix them, and react in the dark at 40°C for 12 hours in the dark to obtain an epoxidation reagent. Then, in a glass reactor with a stirrer, add the obtained waste oil, heat to 40°C, slowly add the epoxidation reagent dropwise under stirring, after the dropwise addition, raise the temperature to 70°C, heat and stir for 3 hours, then cool and stand , separate the oil layer, wash 3 times with 5% sodium bicarbonate solution, then wash 6 times with 60°C deionized water, collect the oil layer, and vacuum rotary evaporation at 70°C for 1 hour until it becomes clear and anhydrous A pale yellow, liquid epoxy gutter oil product is obtained.

[0046] 2. Weigh 50g of epoxy waste oil and 0.05g of hydroquinone obtained in the prev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com