Self-cleaning glass shower door and production method thereof

A production method and shower door technology, applied in the field of shower doors, can solve the problems of late users knowing the shower room, easy to ignore, slipping and other problems, and achieve the effects of reducing time, cost and water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

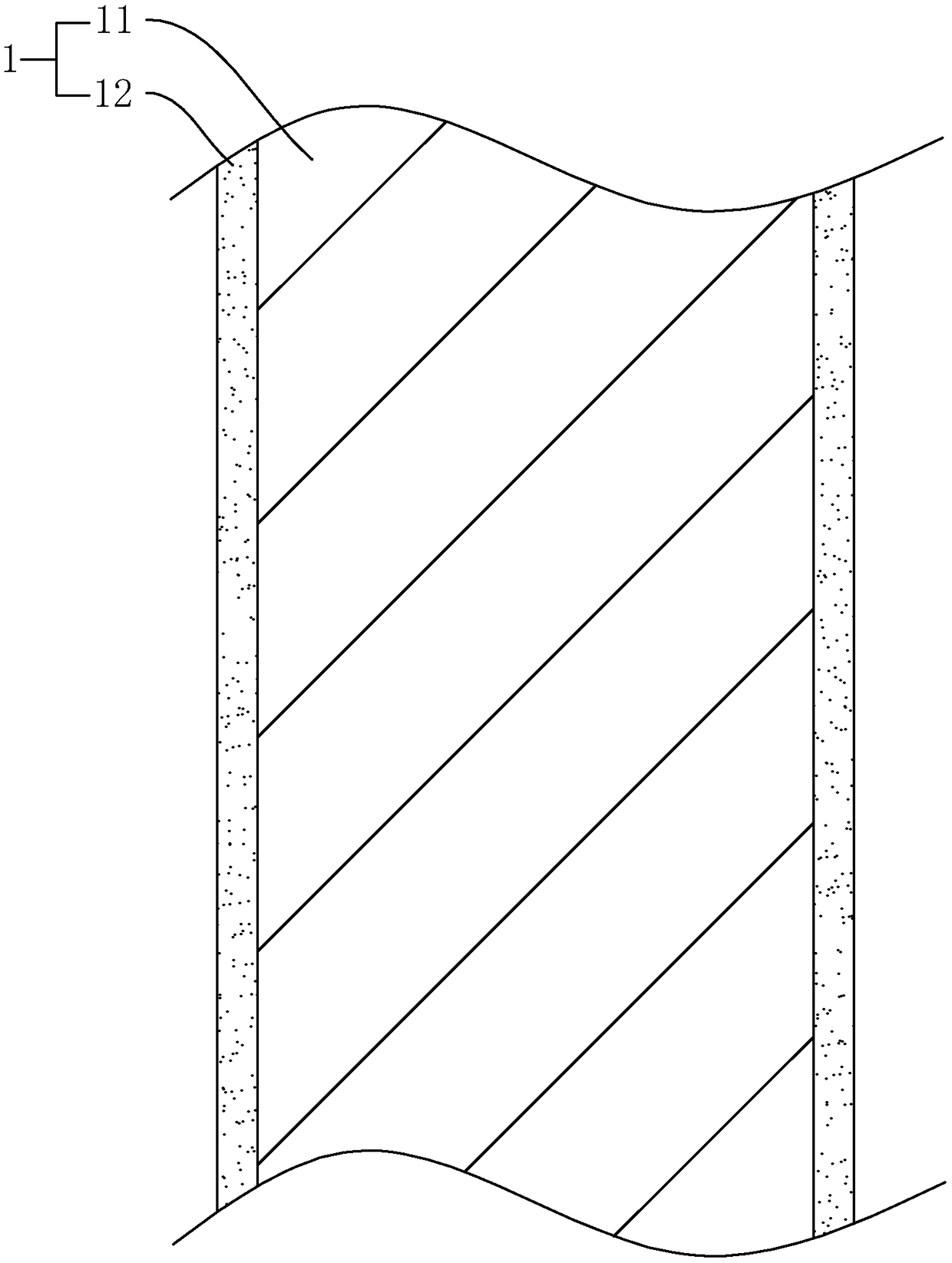

[0074] A method for producing a self-cleaning glass shower door, comprising the steps of,

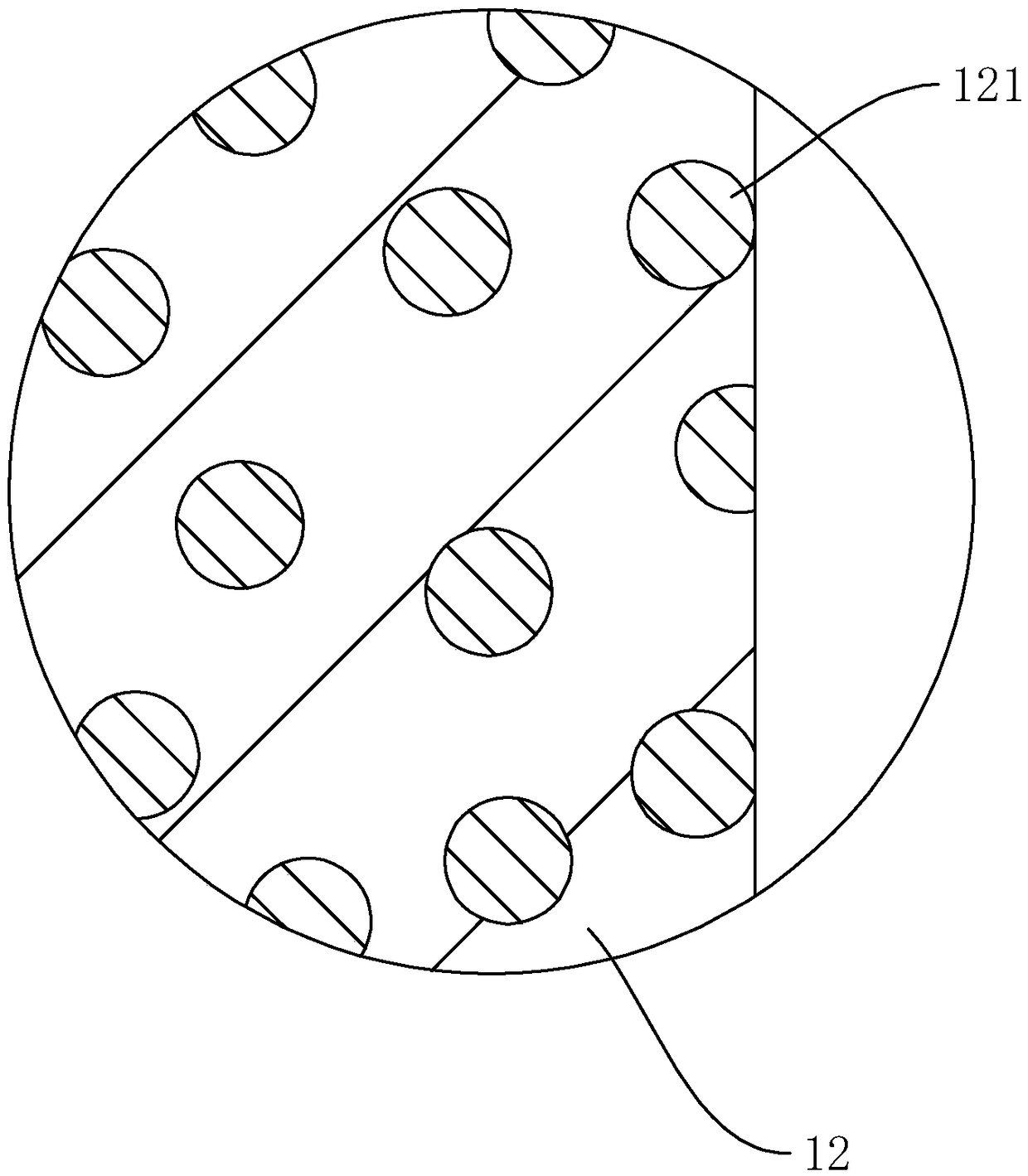

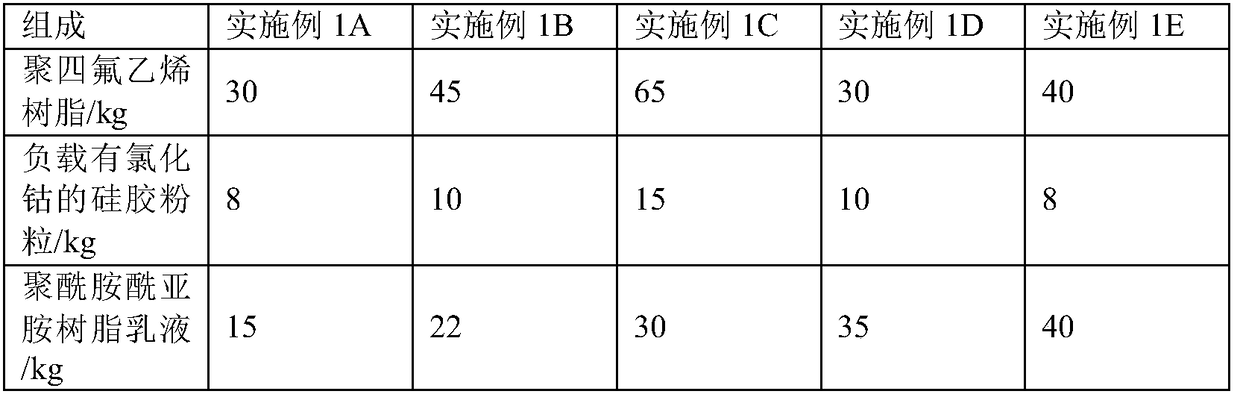

[0075] S1: Weigh polytetrafluoroethylene resin emulsion containing 30-65 parts of polytetrafluoroethylene resin, 8-15 parts of silica gel powder loaded with cobalt chloride, and 15-50 parts of polyamide-imide resin in parts by mass. Parts of polyamideimide resin emulsion and mixed, to obtain self-cleaning paint after mixing;

[0076] S2: Cut the glass plate, and perform surface treatment operations such as grinding and pickling on the surface of the glass plate to obtain the plate body;

[0077] S3: spraying the self-cleaning paint obtained in S1 evenly on the surface of the panel to obtain a prefabricated door panel;

[0078] S4: After the coating is cured, install handles, door frames and other components on the prefabricated door panel to obtain the finished glass shower door.

[0079] According to the production method of the above-mentioned self-cleaning glass shower door, embodi...

Embodiment 2

[0091] A method for producing a self-cleaning glass shower door, based on the first embodiment, the difference is that S1 is divided into the following steps,

[0092] S1.1: Weigh 18-30 parts of ethanol in parts by mass and dilute with deionized water to prepare 30-50 parts of an aqueous solution, wherein the proportion of ethanol in the aqueous solution is 60wt%;

[0093] S1.2: Weigh 20-45 parts of water-based acrylic resin and 5-8 parts of sodium dodecylbenzenesulfonate in parts by mass, add them to the aqueous solution and mix to obtain a premix;

[0094] S1.3: Weigh the polytetrafluoroethylene resin emulsion containing 30-65 parts of polytetrafluoroethylene resin, 8-15 parts of silica gel powder loaded with cobalt chloride, and 15 parts of polyamide-imide resin in parts by mass. -50 parts of polyamideimide resin emulsion is added to the premix and mixed to obtain a self-cleaning coating;

[0095] Steps S2, S3 and S4 are the same as those in Embodiment 1.

[0096] Accordi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| Brookfield viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com