Organic silicon flame-retardant pressure-sensitive adhesive tape and preparation method thereof

A technology of pressure-sensitive adhesive tape and silicone, applied in adhesives, pressure-sensitive films/sheets, film/sheet-shaped adhesives, etc., can solve the problems of by-products polluting the environment, few varieties, and low safety. Achieve the effects of improving the effect of flame retardancy and smoke suppression, convenient preparation steps, and reducing the propagation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

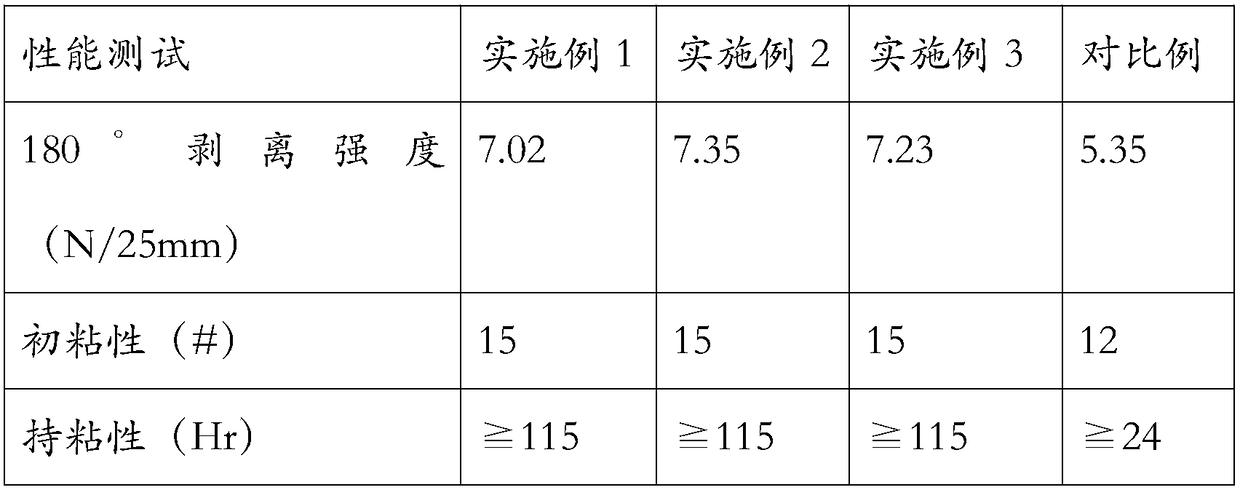

Examples

preparation example Construction

[0038] The preparation method of the above-mentioned organosilicon flame-retardant pressure-sensitive adhesive tape includes,

[0039] Step (1) taking a piece of release paper, pre-coating the adhesive on the release paper to obtain the first release paper with the adhesive;

[0040] Step (2) Dry the first release paper with adhesive through an electric blast drying oven set at 120°C for 10 minutes, take it out and cool it to room temperature;

[0041] Step (3) transferring the cooled first release paper to one side of the substrate layer, and peeling off the release paper simultaneously;

[0042] Step (4) Take another piece of release paper, repeat step (1) and step (2) to obtain the second release paper with adhesive, and then paste the pre-coated on the second release paper on the The other side of the substrate layer is rolled together with the release paper to obtain a silicone flame-retardant pressure-sensitive adhesive tape.

Embodiment 1

[0045] A silicone flame-retardant pressure-sensitive adhesive tape comprises a base material layer, an adhesive layer and a release layer.

[0046] The flame retardant filler is prepared from the following components in parts by weight: 30 parts of modified plant fibers, 8 parts of asbestos powder, 6 parts of flame retardant fibers, 3 parts of nano aluminum hydroxide, and 10 parts of vegetable glue.

[0047] The modified plant fiber is made by modifying the plant fiber, further, the modified plant fiber is made by modifying the plant fiber, the plant fiber is taken from the plant stem, and the plant fiber is preferably sisal fiber .

[0048] The modification method of the modified plant fiber is as follows: in parts by weight, add 8 parts of anhydrous acetone, 8 parts of divinyltetramethyldisiloxane, and 4 parts of nano-magnesium hydroxide in the dispersion tank successively, stir, heat up to 45-55°C, placed in an ultrasonic stirring instrument with a power above 60KW, and st...

Embodiment 2

[0061] A silicone flame-retardant pressure-sensitive adhesive tape comprises a base material layer, an adhesive layer and a release layer.

[0062] The flame retardant filler is prepared from the following components in parts by weight: 40 parts of modified plant fibers, 9 parts of asbestos powder, 7 parts of flame retardant fibers, 4 parts of nano aluminum hydroxide, and 16 parts of vegetable glue.

[0063] Modified plant fibers are obtained by modifying plant fibers. Further, the modified plant fibers are obtained by modifying plant fibers. The plant fibers are obtained from plant stems, and the plant fibers are preferably abaca fiber.

[0064] The modification method of the modified plant fiber is as follows: in parts by weight, add 10 parts of anhydrous acetone, 10 parts of divinyltetramethyldisiloxane, and 5 parts of nano-magnesium hydroxide in the dispersion tank successively, stir and heat up to 45-55°C, placed in an ultrasonic stirring instrument with a power above 60...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com